Automotive brake pad with high graphite content and high friction property and stability and preparation method

A technology with high friction and stability, applied in the field of materials science, can solve the problems of poor friction resistance and stability of brake pads, and achieve the effects of excellent stability of friction performance, simple and easy-to-master process, and low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

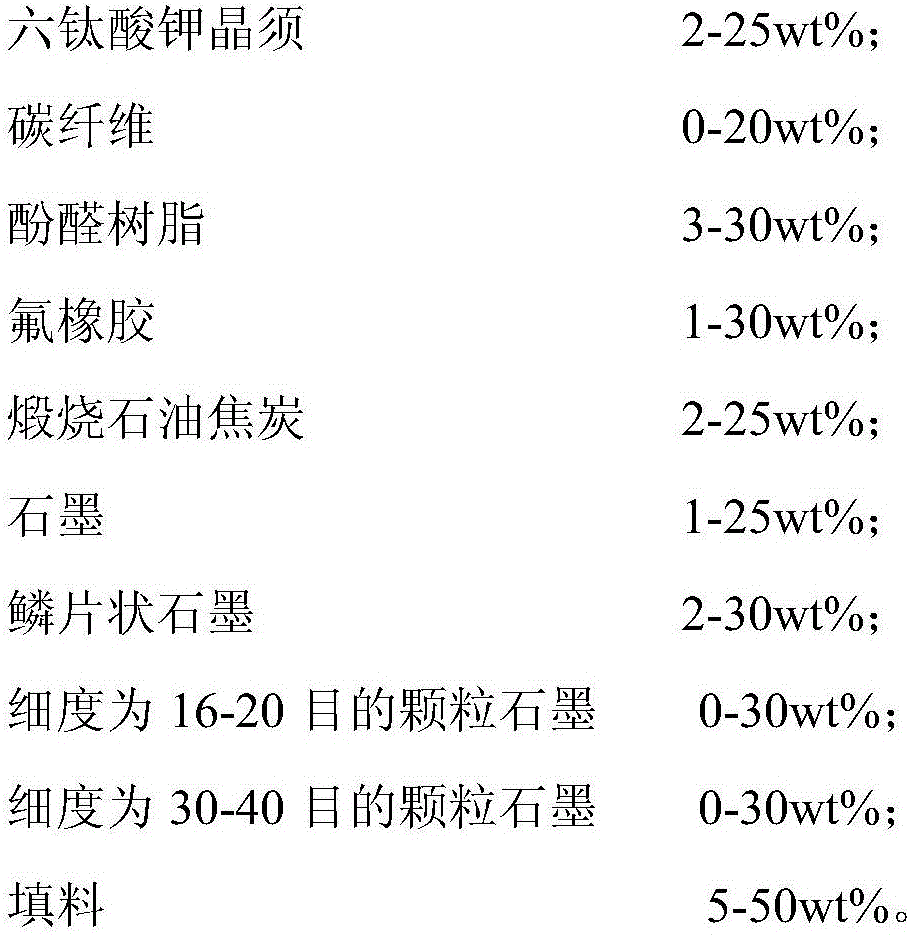

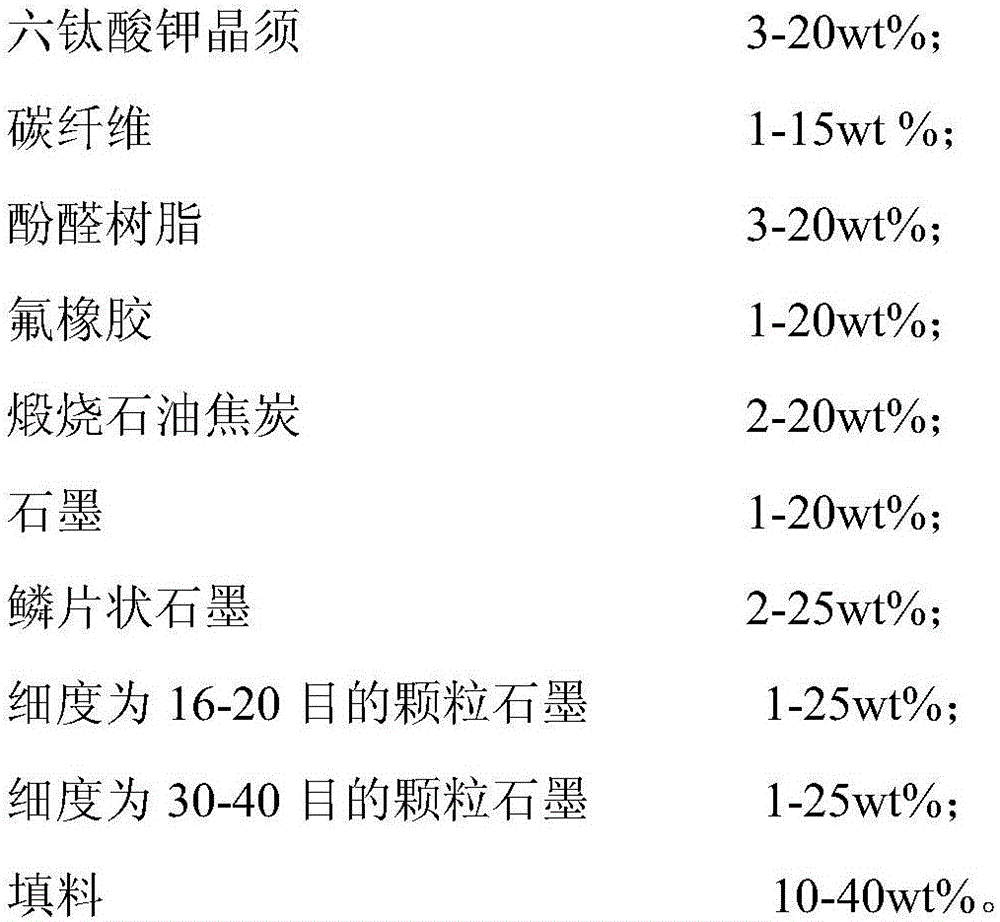

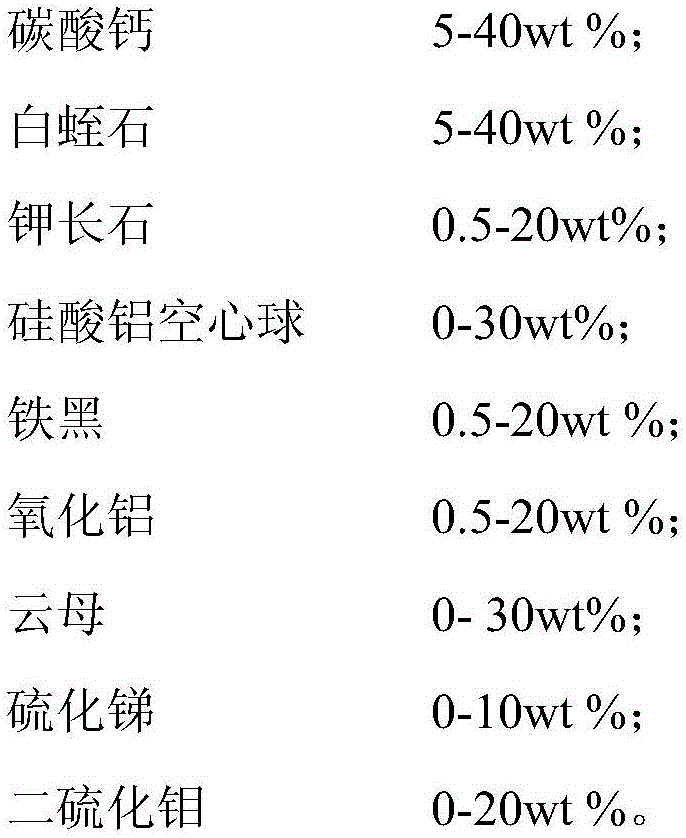

Method used

Image

Examples

Embodiment 1

[0042] Table 1 Embodiment 1 formula (18-3)

[0043] material name weight percentage Potassium hexatitanate whiskers 8 carbon fiber 4 Phenolic Resin 7 fluororubber 6 Calcined Petroleum Coke 6 graphite 10 flake graphite 5 Granular graphite with a fineness of 16-20 mesh 10 Granular graphite with a fineness of 30-40 mesh 11 calcium carbonate 8 white vermiculite 8.5 Potassium feldspar 3 Aluminum silicate hollow ball 4 iron black 3 Aluminum oxide 1.5 Mica 2 Antimony sulfide 1 Molybdenum disulfide 2

Embodiment 2

[0044] Table 2 embodiment 2 formula (18-4)

[0045]

[0046]

Embodiment 3

[0047] Table 3 Embodiment 3 formula (17-2)

[0048]

[0049]

[0050] Table 4 embodiment 4 formula (17-4)

[0051] material name weight percentage Potassium hexatitanate whiskers 8 carbon fiber 4 Phenolic Resin 7 fluororubber 4 Calcined Petroleum Coke 6 graphite 10 flake graphite 5 Granular graphite with a fineness of 16-20 mesh 9 Granular graphite with a fineness of 30-40 mesh 12 calcium carbonate 11 white vermiculite 11 Potassium feldspar 3 Aluminum silicate hollow ball 0 iron black 3 Aluminum oxide 2 Mica 2 Antimony sulfide 1 Molybdenum disulfide 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com