A kind of brake pad with high friction coefficient and preparation method thereof

A technology of high friction coefficient and brake pads, which is applied in the direction of friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of large wear and attenuation of friction coefficient, and achieve low wear and small fluctuation of friction coefficient , the effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

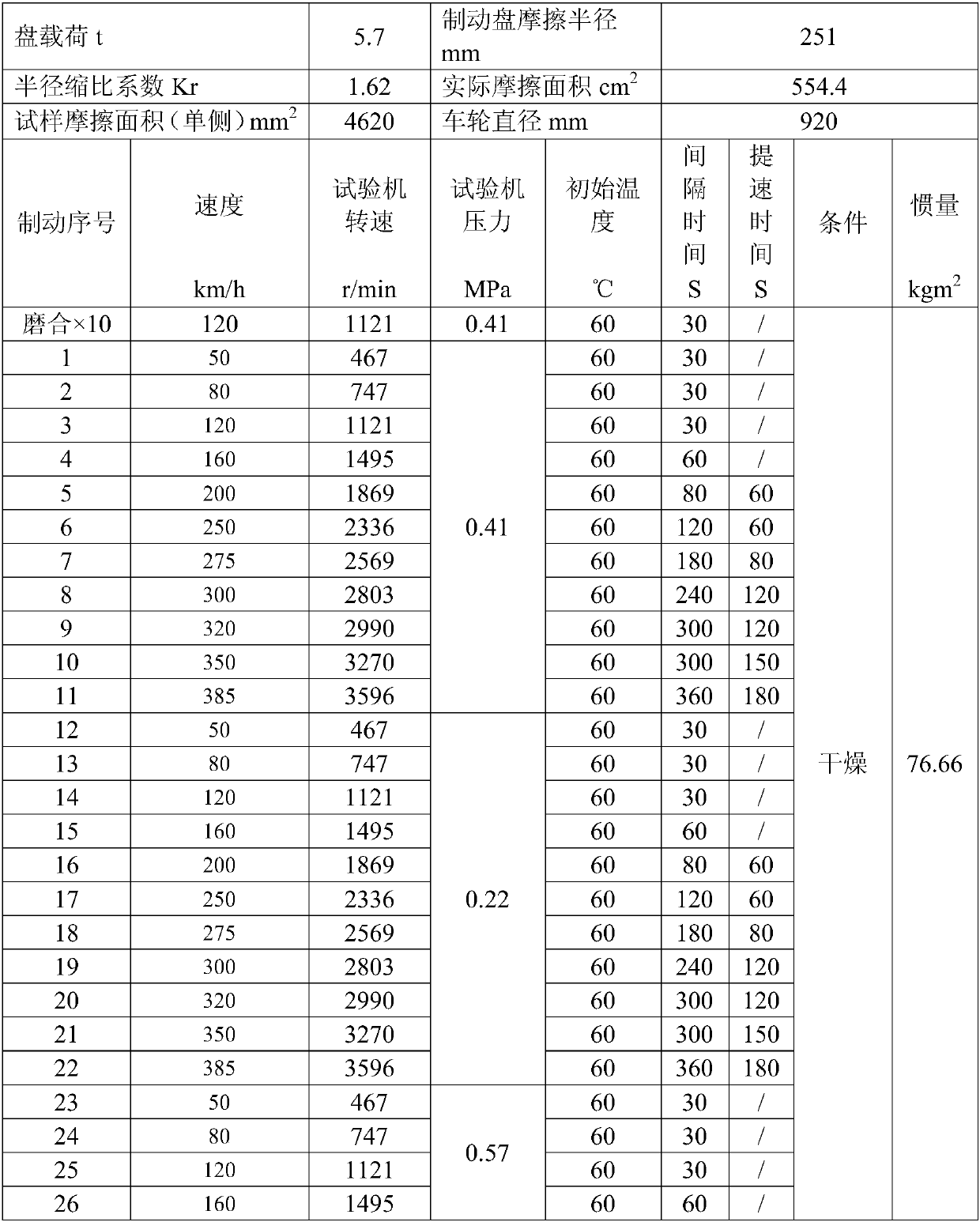

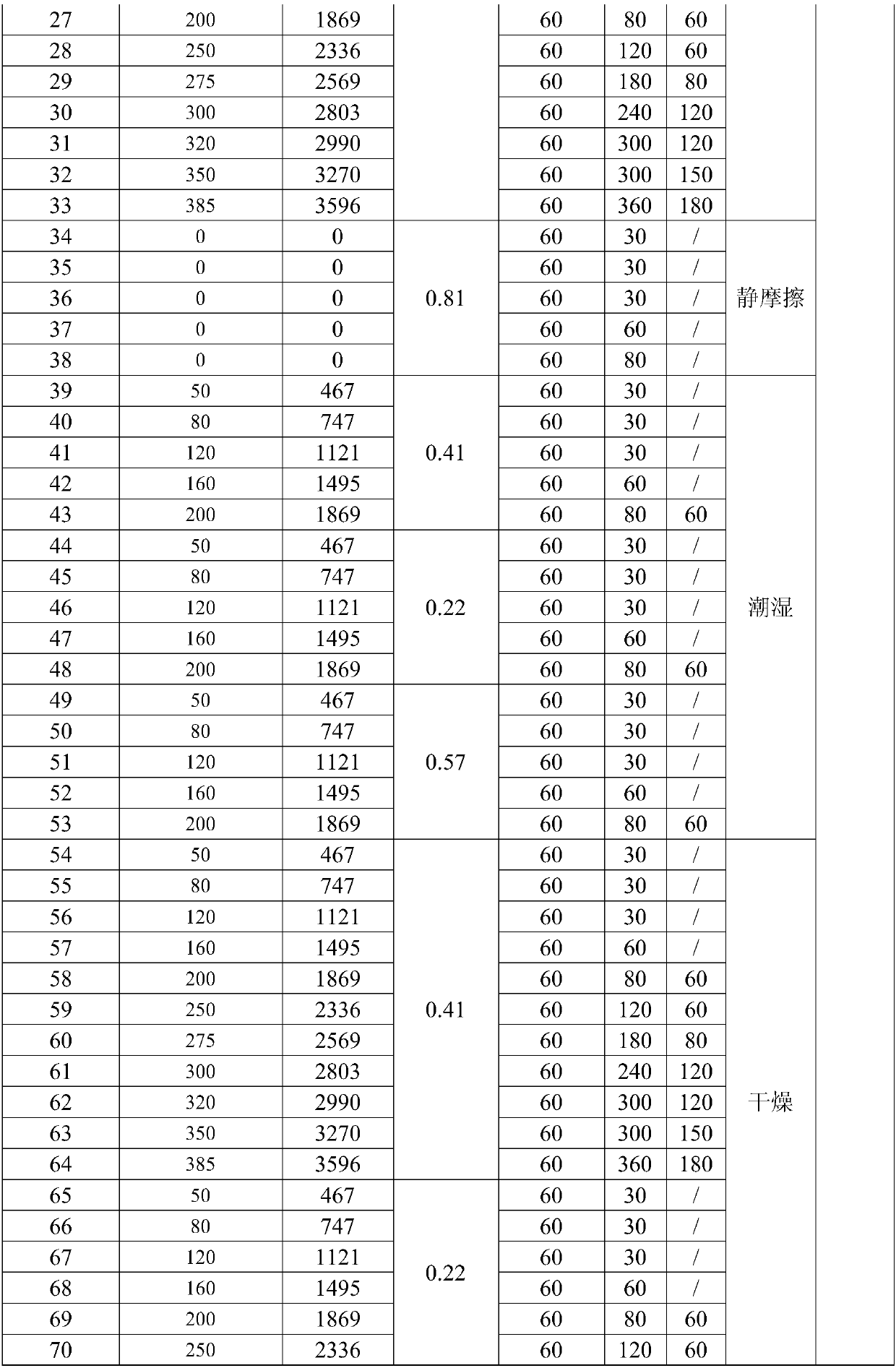

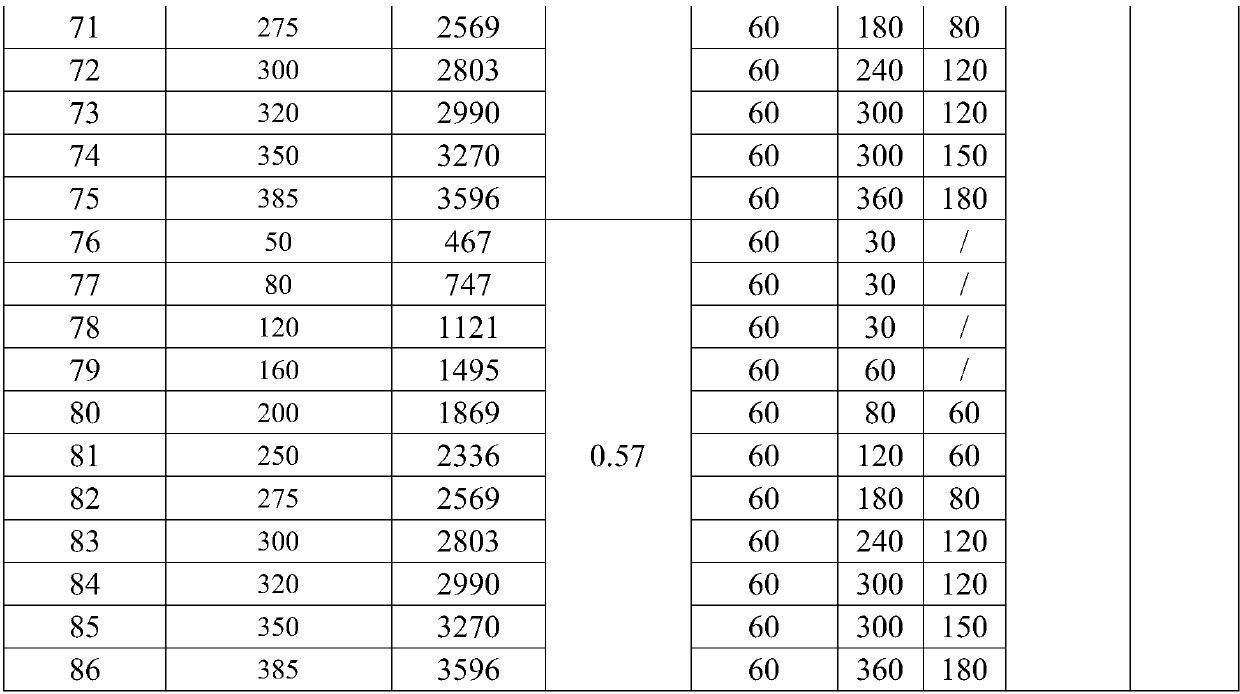

Image

Examples

Embodiment 1

[0039] The brake pad with high friction coefficient described in this embodiment includes the following raw material components:

[0040] Electrolytic copper powder, 52 parts by weight;

[0041] Particle size is 200 mesh eutectoid steel grinding powder, 12 parts by weight;

[0042] Copper-coated graphite powder, 7 parts by weight;

[0043] Ferrous sulfide, 5 parts by weight;

[0044] Electrolytic nickel powder, 6 parts by weight;

[0045] Silicon dioxide, 4 parts by weight;

[0046] Molybdenum oxide, 8 parts by weight.

[0047] The brake pad described in this embodiment is prepared by the following method:

[0048] (1) Weighing each raw material component according to the above parts by weight and placing it in a ball mill for thorough mixing for 4 hours to obtain a mixture;

[0049] (2) Fill the mixture in the step (1) into the mould, hold the pressure for 20s under the pressure of 15MPa to obtain the green body by pressing;

[0050] (3) Use a hot press to directly hea...

Embodiment 2

[0052] The brake pad with high friction coefficient described in this embodiment includes the following raw material components:

[0053] Reduced copper powder, 62 parts by weight;

[0054] Particle size is 300 mesh eutectoid steel grinding powder, 8 parts by weight;

[0055] Copper-coated graphite powder, 13 parts by weight;

[0056] Ferrous sulfide, 2 parts by weight;

[0057] Electrolytic nickel powder, 8 parts by weight;

[0058] Silicon dioxide, 6 parts by weight;

[0059] Molybdenum oxide, 6 parts by weight.

[0060] The brake pad described in this embodiment is prepared by the following method:

[0061] (1) Weighing each raw material component according to the above parts by weight and placing it in a ball mill for thorough mixing for 4 hours to obtain a mixture;

[0062](2) Fill the mixture in the step (1) into the mould, hold the pressure for 15s under the pressure of 20MPa to obtain the green body by pressing;

[0063] (3) Use a hot press to directly heat the ...

Embodiment 3

[0065] The brake pad with high friction coefficient described in this embodiment includes the following raw material components:

[0066] Water atomized copper powder, 57 parts by weight;

[0067] Particle size is 250 mesh eutectoid steel grinding powder, 11 parts by weight;

[0068] Copper-coated graphite powder, 15 parts by weight;

[0069] Ferrous sulfide, 6 parts by weight;

[0070] Reduced nickel powder, 3 parts by weight;

[0071] Silicon dioxide, 5 parts by weight;

[0072] Molybdenum oxide, 12 parts by weight.

[0073] The brake pad described in this embodiment is prepared by the following method:

[0074] (1) Weighing each raw material component according to the above parts by weight and placing it in a ball mill for thorough mixing for 4 hours to obtain a mixture;

[0075] (2) Fill the mixture in the step (1) into the mould, hold the pressure for 10s under the pressure of 25MPa to obtain the green body by pressing;

[0076] (3) Use a hot press to directly heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com