Structure function integrated C/C-Si friction material and preparation method thereof

A friction material and functional technology, applied in the field of structure-function integrated C/C-SiC friction material and preparation, can solve the problems of high preparation cost, unstable friction performance, delamination, etc. Cycle, the effect of improving the stability of friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

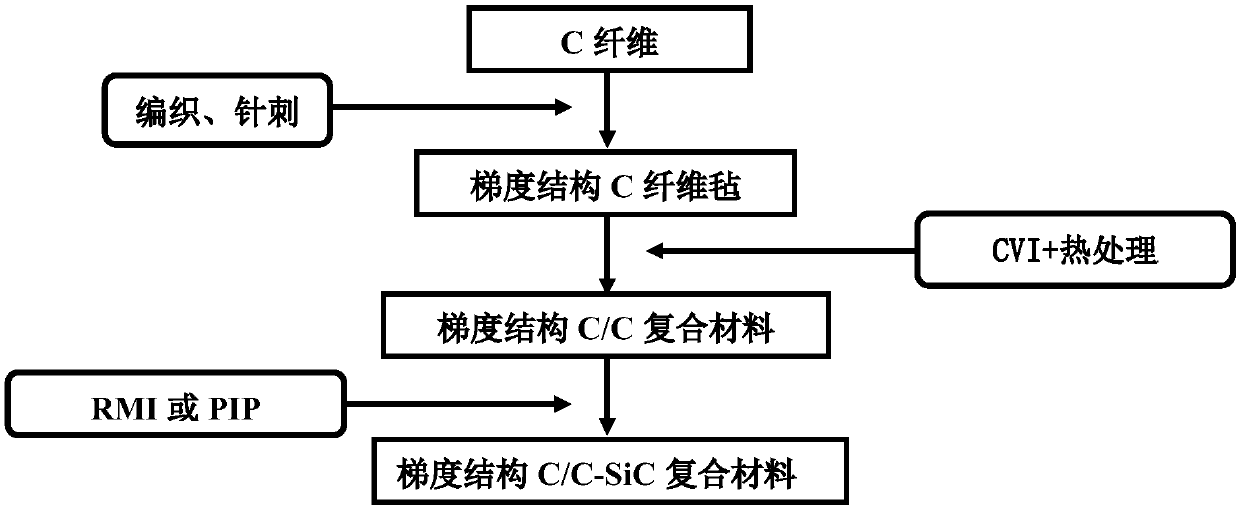

Method used

Image

Examples

Embodiment 1

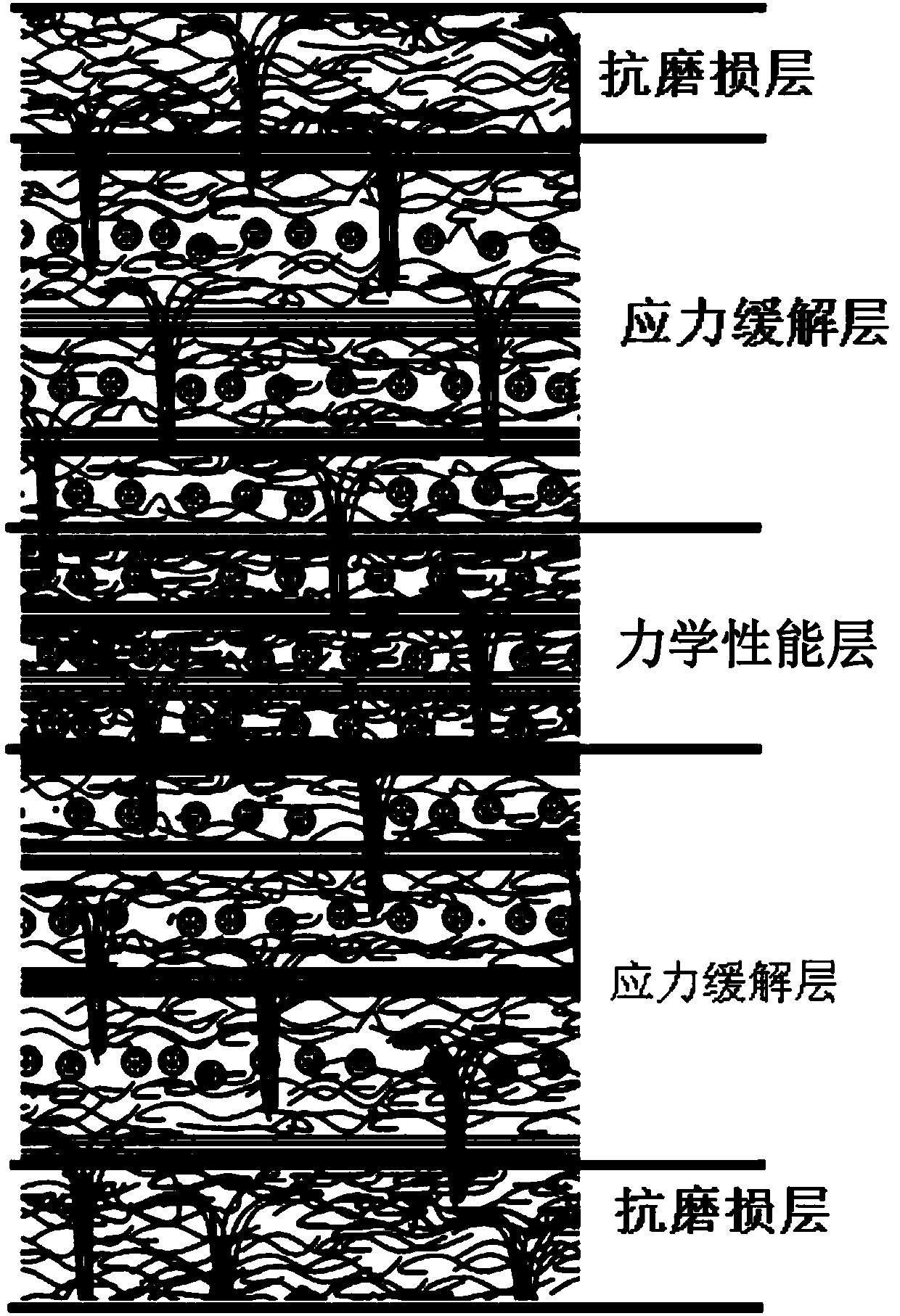

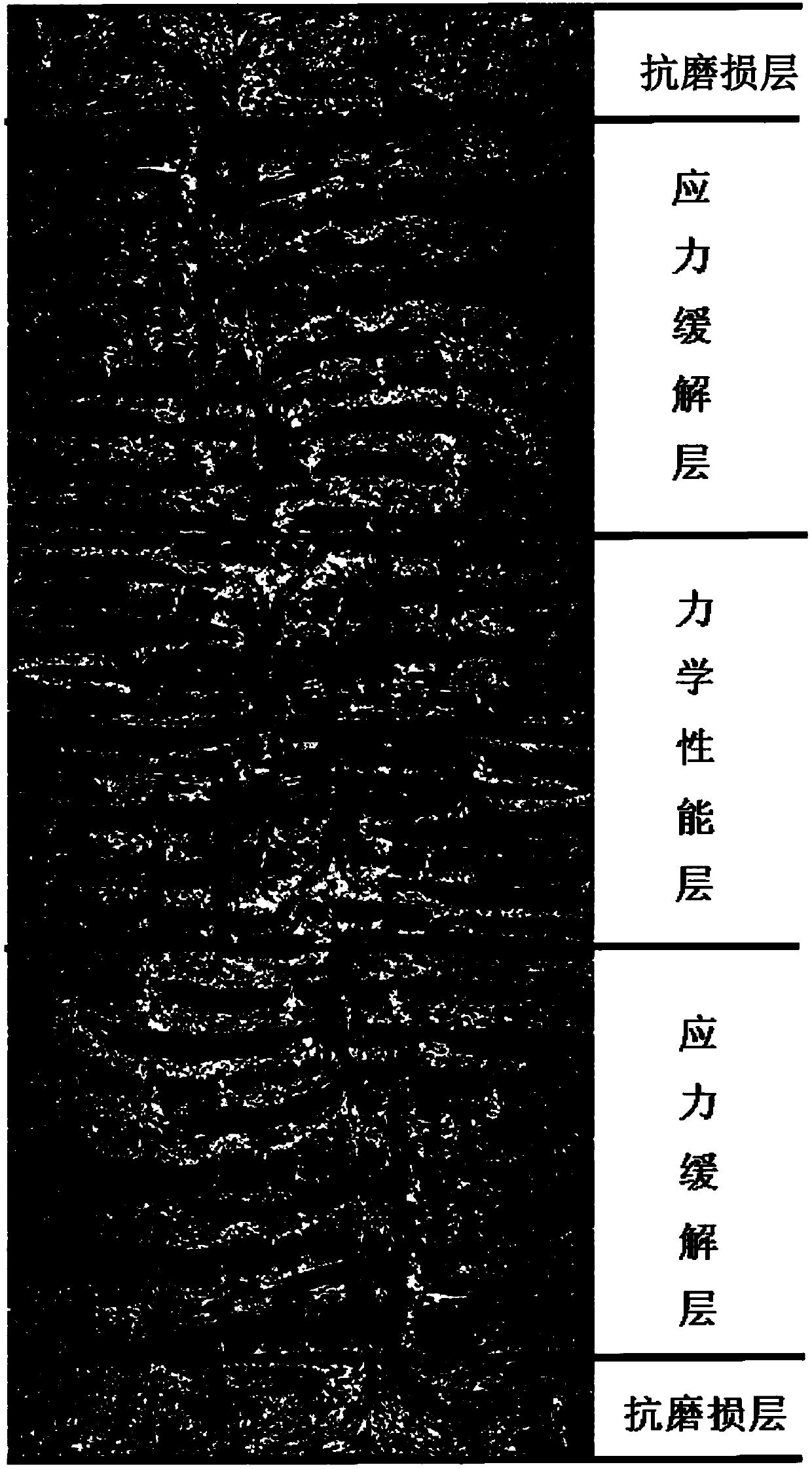

[0032] Step 1.1: First, make PAN-based T-300 (6-50K) carbon fiber into short-fiber mesh tires and non-weft fabrics, then stack the single-layer mesh tires to a certain thickness, and then adopt the method of relay acupuncture to make them integrated , to obtain the anti-wear layer carbon fiber preform structure A1, whose bulk density is 0.2g / cm 3 .

[0033] Step 1.2: Then prepare the stress relief layer carbon fiber prefabricated body structure B1 on the structure of step 1.1. The preparation method is to make a single layer of 0° no-weft fabric, 1-10 layers of carbon fiber mesh tire, 90° no-weft fabric, 1-10 layers The carbon fiber mesh tires are stacked in sequence to a certain thickness, and then the relay needle punching method is used to make it integrated with the anti-wear layer carbon fiber prefabricated structure A1 prepared in step 1.1. During the layering process, it is necessary to gradually reduce the number of mesh layers and the spacing between fiber bundles in...

Embodiment 2

[0040] Step 2.1: First, make PAN-based T-300 (6-50K) carbon fiber into short-fiber mesh tires and non-weft fabrics, then stack the single-layer mesh tires to a certain thickness and then use relay-type acupuncture to make them integrated , to obtain the anti-wear layer carbon fiber preform structure A1, whose bulk density is 0.2g / cm 3 .

[0041] Step 2.2: Then prepare the stress relief layer carbon fiber prefabricated body structure B1 on the structure of step 1.1. The preparation method is to make a single layer of 0° no weft cloth, 1 to 10 layers of carbon fiber mesh, 90° no weft cloth, 1 to 10 layers The carbon fiber mesh tires are stacked in sequence to a certain thickness, and then the relay needle punching method is used to make it integrated with the anti-wear layer carbon fiber prefabricated structure A1 prepared in step 1.1. During the layering process, it is necessary to gradually reduce the number of mesh layers and the distance between the fiber bundles in the non...

Embodiment 3

[0048] Step 3.1: First, make PAN-based T-300 (6-50K) carbon fiber into short-fiber mesh tires and non-weft fabrics, then stack the single-layer mesh tires to a certain thickness, and then adopt the method of relay acupuncture to make them integrated , to obtain the anti-wear layer carbon fiber preform structure A1, whose bulk density is 0.2g / cm 3 .

[0049] Step 3.2: Then prepare the stress relief layer carbon fiber prefabricated body structure B1 on the structure of step 1.1. The preparation method is to make a single layer of 0° no weft cloth, 1-10 layers of carbon fiber mesh, 90° no weft cloth, 1-10 layers The carbon fiber mesh tires are stacked in sequence to a certain thickness, and then the relay needle punching method is used to make it integrated with the anti-wear layer carbon fiber prefabricated structure A1 prepared in step 1.1. During the layering process, it is necessary to gradually reduce the number of mesh layers and the distance between the fiber bundles in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com