Freight car compartment powder metallurgy brake block

A powder metallurgy, carriage technology, applied in friction linings, mechanical equipment, etc., can solve the problems of unstable friction coefficient, wheel tread damage, poor heat dissipation, etc., to achieve reasonable shape structure design, stable friction performance, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

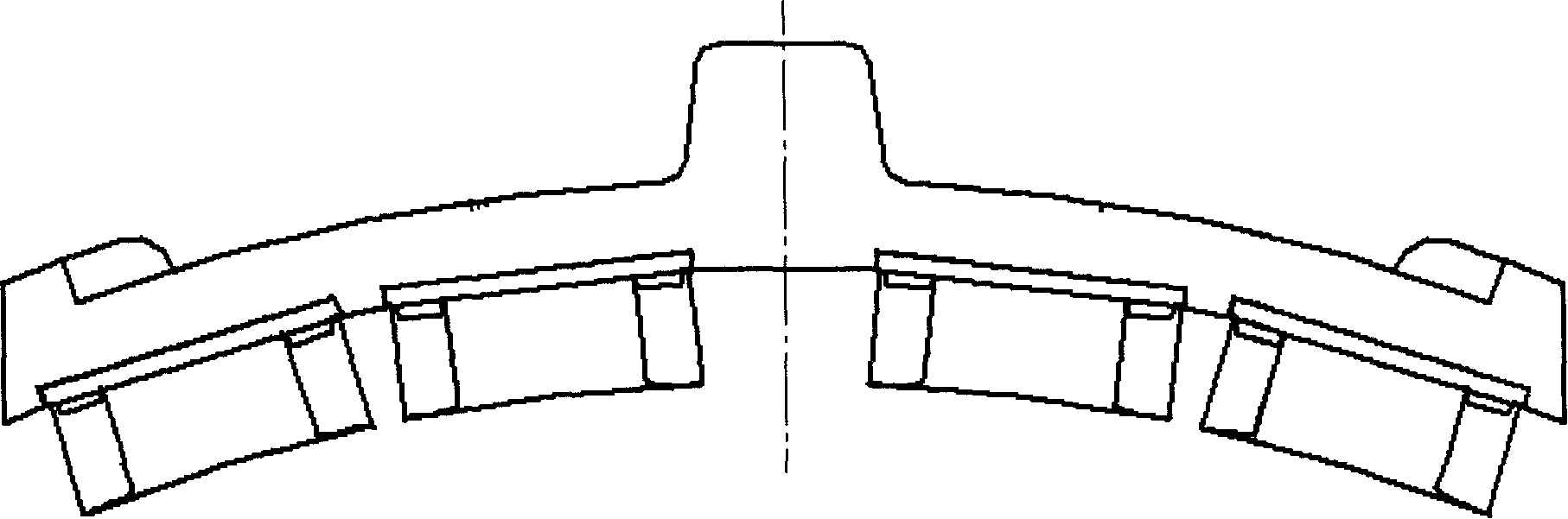

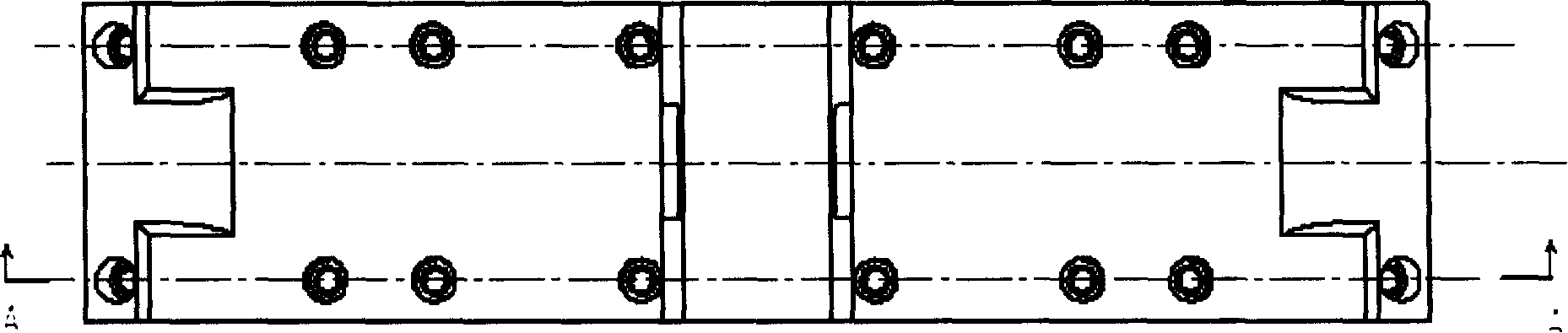

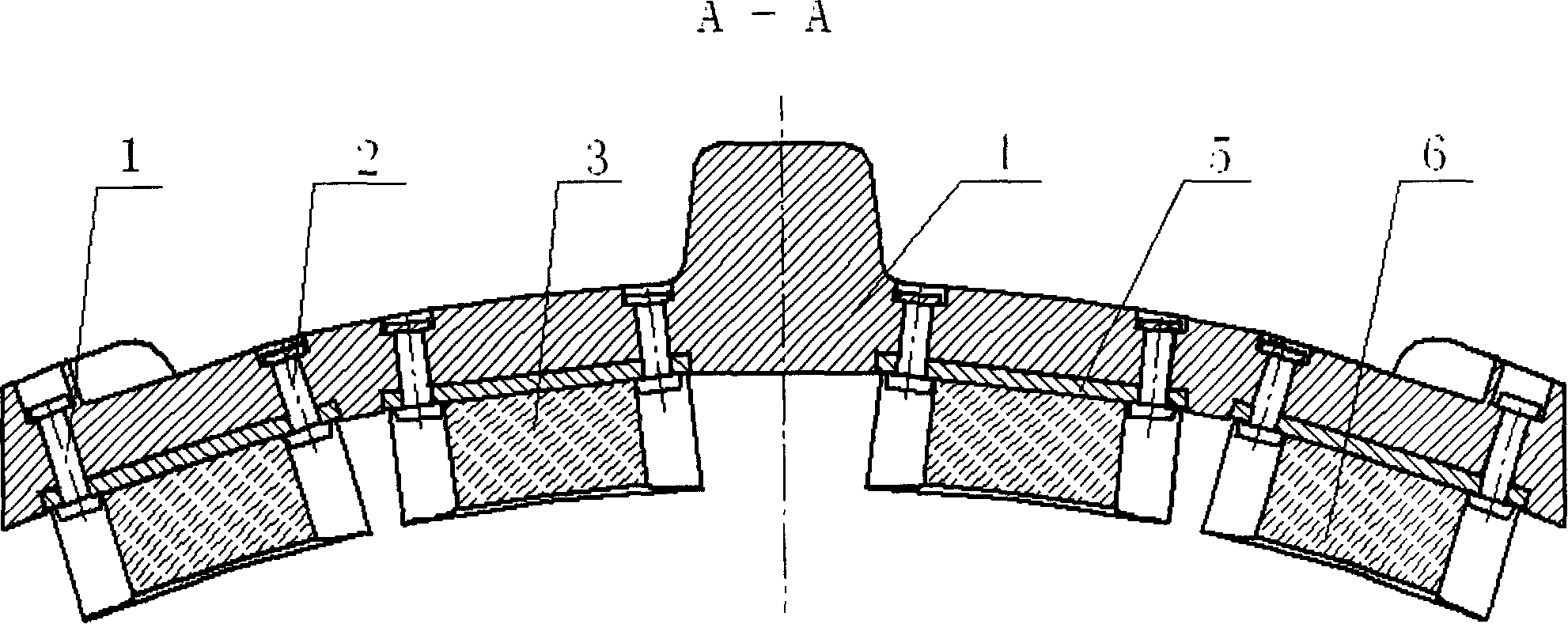

[0019] The powder metallurgy brake shoe of the truck compartment of the present invention is mainly composed of a tile back 4 and four brake blocks 3, the tile back 4 is formed by one-time casting of nodular cast iron or low-carbon cast steel; the brake block 3 is composed of a skeleton 5 and a powder metallurgy friction block 6; The powder metallurgy friction block 6 is made by mixing various powder metallurgy materials evenly in proportion, and after cold pressing, it is heated and pressure-sintered with the skeleton 5; the tile back 4 and the brake block 3 are welded around the rigid back 5 through the welding point 7 to the tile back or riveted together with the tile back through rivet 1 and rivet 2. The powder metallurgy friction block 6 is made of copper powder, tin powder, aluminum powder, molybdenum disulfide powder, graphite powder, alumina, iron powder, etc. according to the following weight ratio:

[0020] Copper powder 2~10 Tin powder 1~7 Aluminum powder 5~11 Molyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com