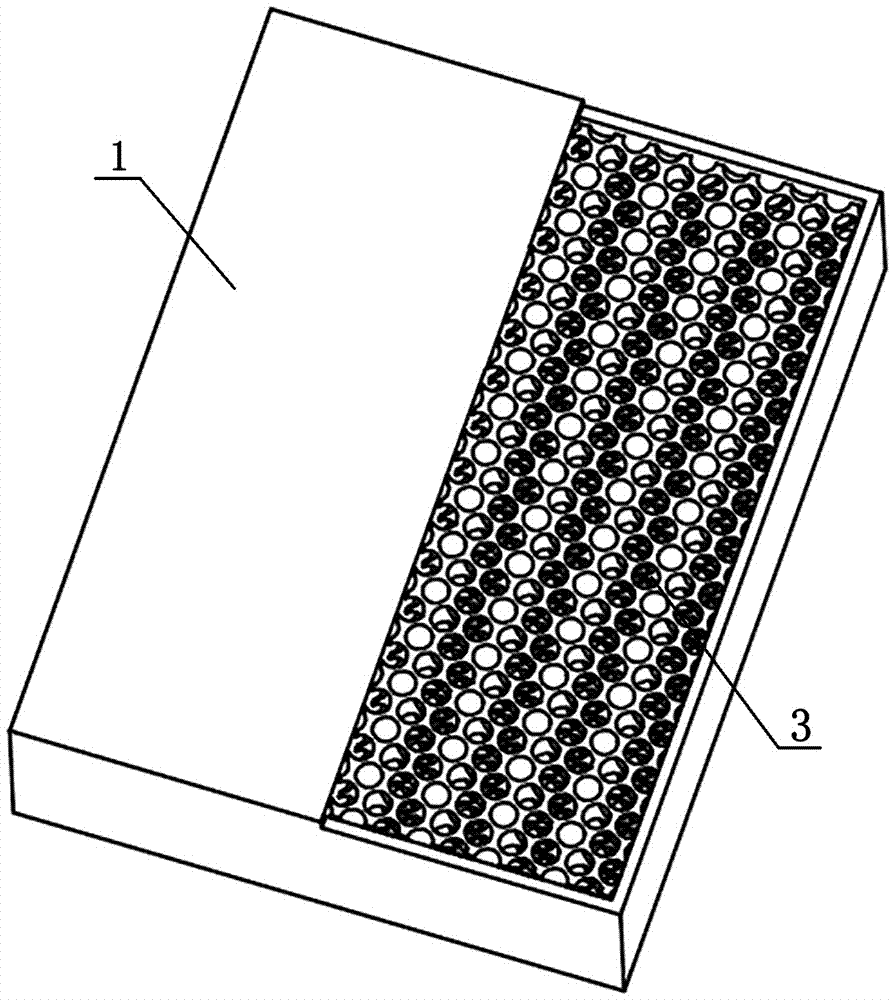

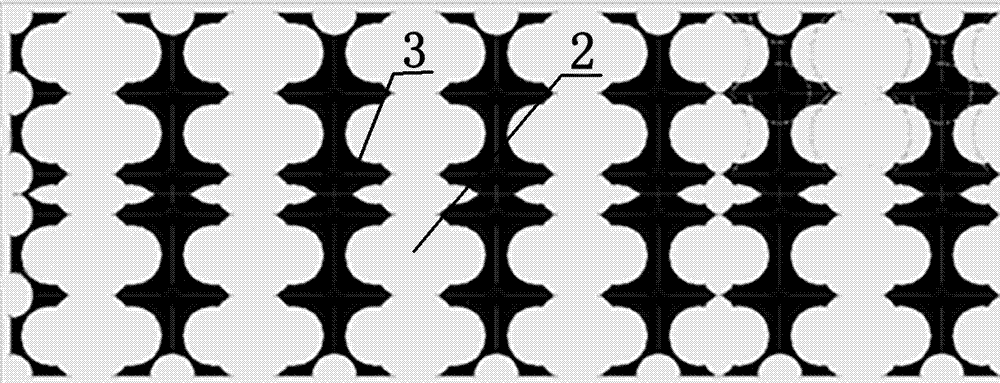

Lost foam casting method of three-dimensional network ceramic-iron-based composite material

An iron-based composite material and lost foam casting technology, which is applied in the direction of casting molding equipment, molds, and mold components, can solve the problems of poor economy, poor wettability between ceramics and metal substrates, etc., and achieve poor wettability , Improving the comprehensive mechanical properties and hindering the effect of interface reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

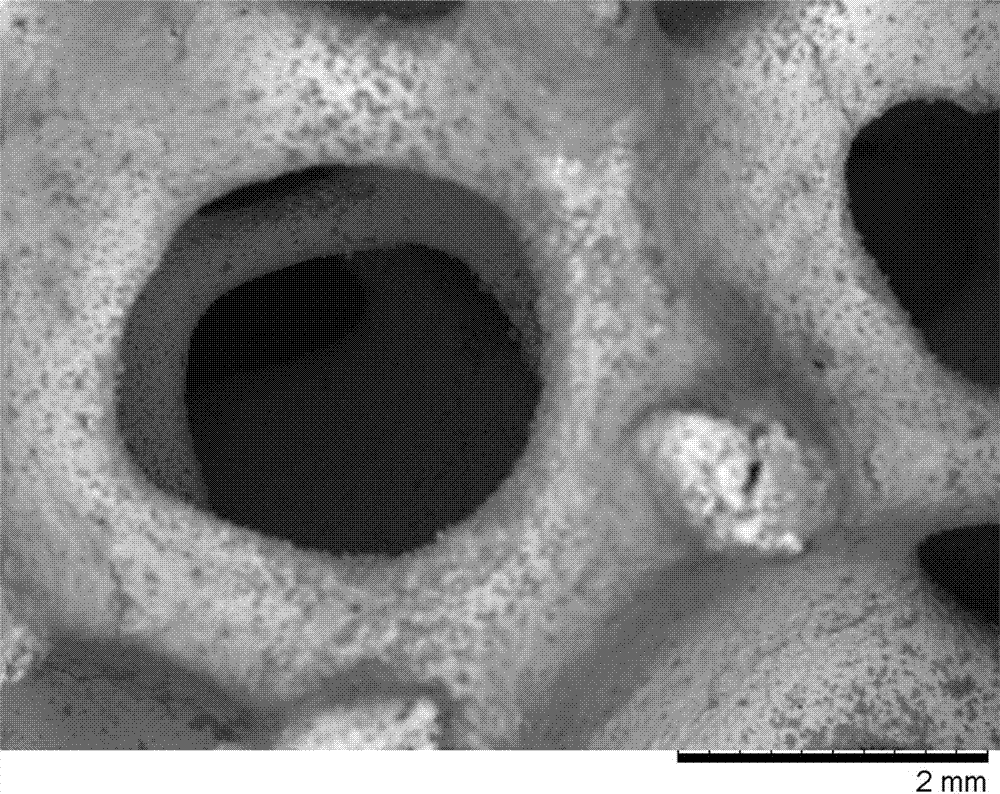

[0053] (1) Perform surface roughening, neutralization, sensitization, activation and reduction pretreatment on the three-dimensional network ceramic 3 at room temperature, so that hypophosphite ions are attached to the surface of the ceramic, and the plating solution with nickel sulfate as the main salt includes: Nickel sulfate solution 20g / L, sodium hypophosphite solution 30g / L, sodium acetate solution 20g / L, sodium citrate solution 5g / L and lead chloride solution 0.003g / L configure the electroless plating solution and heat up to 70°C. Nickel ions are chemically reduced to metal nickel, deposited on the surface of the ceramic and form a Ni-P composite coating, and electroless nickel plating is performed on the surface of the three-dimensional network ceramic 3; after plating, the surface appearance of the three-dimensional network ceramic 3 is as follows image 3 As shown, the obtained Ni-P composite coating is uniform, dense, and firmly attached to the surface of the three-di...

Embodiment 2

[0063] (1) Perform surface roughening, neutralization, sensitization, activation and reduction pretreatment on the three-dimensional network ceramic 3 at room temperature, so that hypophosphite ions are attached to the surface of the ceramic, and the plating solution with nickel sulfate as the main salt includes: Nickel sulfate solution 28g / L, sodium hypophosphite solution 35g / L, sodium acetate solution 25g / L, sodium citrate solution 10g / L and lead chloride solution 0.010g / L configure the chemical plating solution and heat up to 80°C. Nickel ions are chemically reduced to metal nickel, deposited on the surface of the ceramic and form a Ni-P composite coating, and electroless nickel plating is performed on the surface of the three-dimensional network ceramic 3; after plating, the surface appearance of the three-dimensional network ceramic 3 is as follows Figure 4 As shown, the obtained Ni-P composite coating is uniform, dense, and firmly attached to the surface of the three-dim...

Embodiment 3

[0073] (1) Perform surface roughening, neutralization, sensitization, activation and reduction pretreatment on the three-dimensional network ceramic 3 at room temperature, so that hypophosphite ions are attached to the surface of the ceramic, and the plating solution with nickel sulfate as the main salt includes: Nickel sulfate solution 25g / L, sodium hypophosphite solution 32g / L, sodium acetate solution 22g / L, sodium citrate solution 8g / L and lead chloride solution 0.005g / L configure the electroless plating solution and heat up to 75°C. Nickel ions are chemically reduced to metal nickel, deposited on the surface of the ceramic and form a Ni-P composite coating, and electroless nickel plating is performed on the surface of the three-dimensional network ceramic 3; after plating, the surface appearance of the three-dimensional network ceramic 3 is as follows Figure 5 As shown, the obtained Ni-P composite coating is uniform, dense, and firmly attached to the surface of the three-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com