Carbon-based magnetic wear-resisting particle for friction material and preparation method thereof

A friction material and wear-resistant particle technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as not being fully satisfied, and achieve the effects of low cost, broad market prospects, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

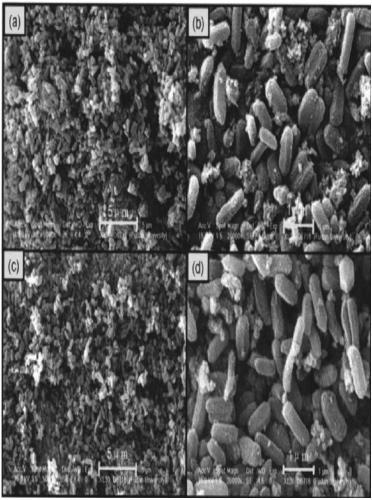

Image

Examples

Embodiment 1

[0021] The preparation method is:

[0022] (1) Mixing: Put 2200g of pretreated carbon fiber and 3100g of pretreated silicon carbide fiber into a high-speed mixer, mix for 6 minutes to form carbon fiber silicon carbide composite fiber, and then take it out of the high-speed mixer for use;

[0023] (2) Ball milling: mix the mixed carbon fiber silicon carbide composite fiber with 1100g polyethylene oxide, 600g fatty acid, 1000g graphite, 500g NdFeB, 600g alnico, 1200g hexahydrate ferric chloride, 1200g orthosilicate Ethyl vinegar and 400g of titanium tetraisopropoxide were put into the ball mill at a speed of 450rpm / min, and mixed for 180 minutes to make it evenly mixed and then taken out for later use;

[0024] (3) Calcination: put the homogeneously mixed mixture into a tube furnace and pass through argon to carbonize at 900°C for 300 minutes;

[0025] (4) Etching: Put the carbonized mixture into 90% glacial acetic acid to dissolve and etch for 90 minutes, then take out the car...

Embodiment 2

[0030] The preparation method is:

[0031] (1) Mixing: Put 2500g of pretreated carbon fiber and 3500g of pretreated silicon carbide fiber into a high-speed mixer, mix for 8 minutes to form carbon fiber silicon carbide composite fiber, and then take it out of the high-speed mixer for use;

[0032] (2) Ball milling: mix the mixed carbon fiber silicon carbide composite fiber with 1300g polyethylene oxide, 700g fatty acid, 1200g graphite, 600g NdFeB, 700g alnico, 1500g hexahydrate ferric chloride, 1300g orthosilicate Ethyl vinegar and 450g of titanium tetraisopropoxide are put into the ball mill at a speed of 480rpm / min and mixed for 200 minutes to make it evenly mixed and then taken out for later use;

[0033] (3) Calcination: Put the homogeneously mixed mixture into a tube furnace and pass through argon gas to carbonize at 920°C for 330-minutes;

[0034] (4) Etching: Put the carbonized mixture into 92% glacial acetic acid to dissolve and etch for 95 minutes, then take out the c...

Embodiment 3

[0039] (1) Mixing: Put 2800g of pretreated carbon fibers and 3900g of pretreated silicon carbide fibers into a high-speed mixer, mix for 9 minutes to form carbon fiber silicon carbide composite fibers, and then take them out from the high-speed mixer for use;

[0040] (2) Ball milling: mix the mixed carbon fiber silicon carbide composite fiber with 1500g polyethylene oxide, 800g fatty acid, 1200g graphite, 700g NdFeB, 800g alnico, 1700g hexahydrate ferric chloride, 1400g orthosilicate Ethyl vinegar and 600g of titanium tetraisopropoxide are put into the ball mill at a speed of 500rpm / min and mixed for 220 minutes to make it evenly mixed and then taken out for later use;

[0041] (3) Calcination: put the homogeneously mixed mixture into a tube furnace and pass through argon gas to carbonize at 950°C for 360 minutes;

[0042] (4) Etching: Put the carbonized mixture into 95% glacial acetic acid to dissolve and etch for 100 minutes, then take out the carbonized mixture and wash it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com