Sealing gasket for exhaust system of supercharged engine and machining method thereof

A supercharged engine and exhaust system technology, applied in the direction of flange connections, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of small sealing area, poor sealing effect, high temperature and high pressure gas leakage, etc. area, improving the sealing effect, and compensating for the effect of processing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical ideas claimed in the present invention more clearly.

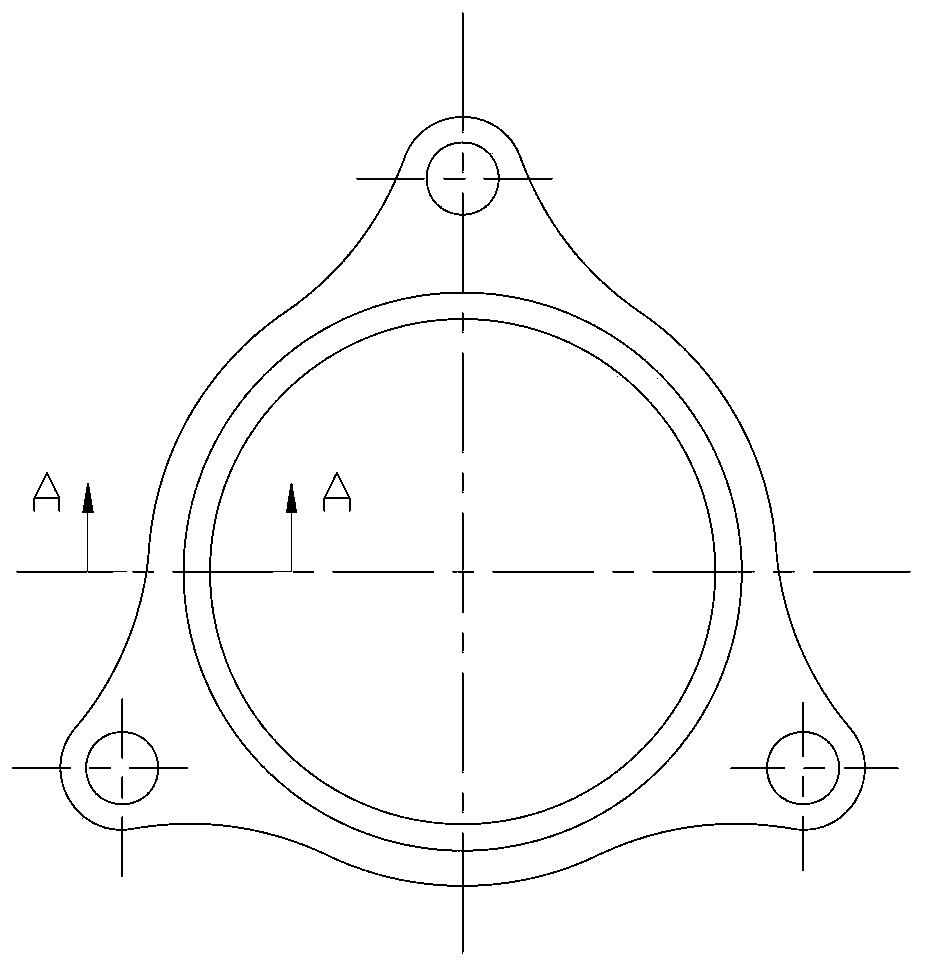

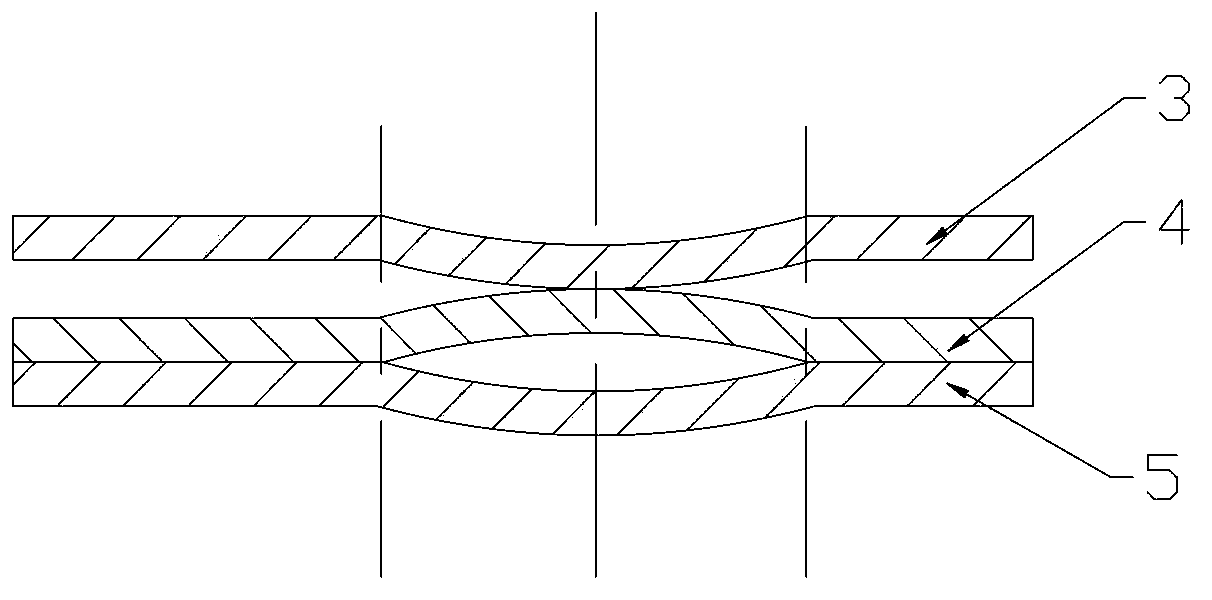

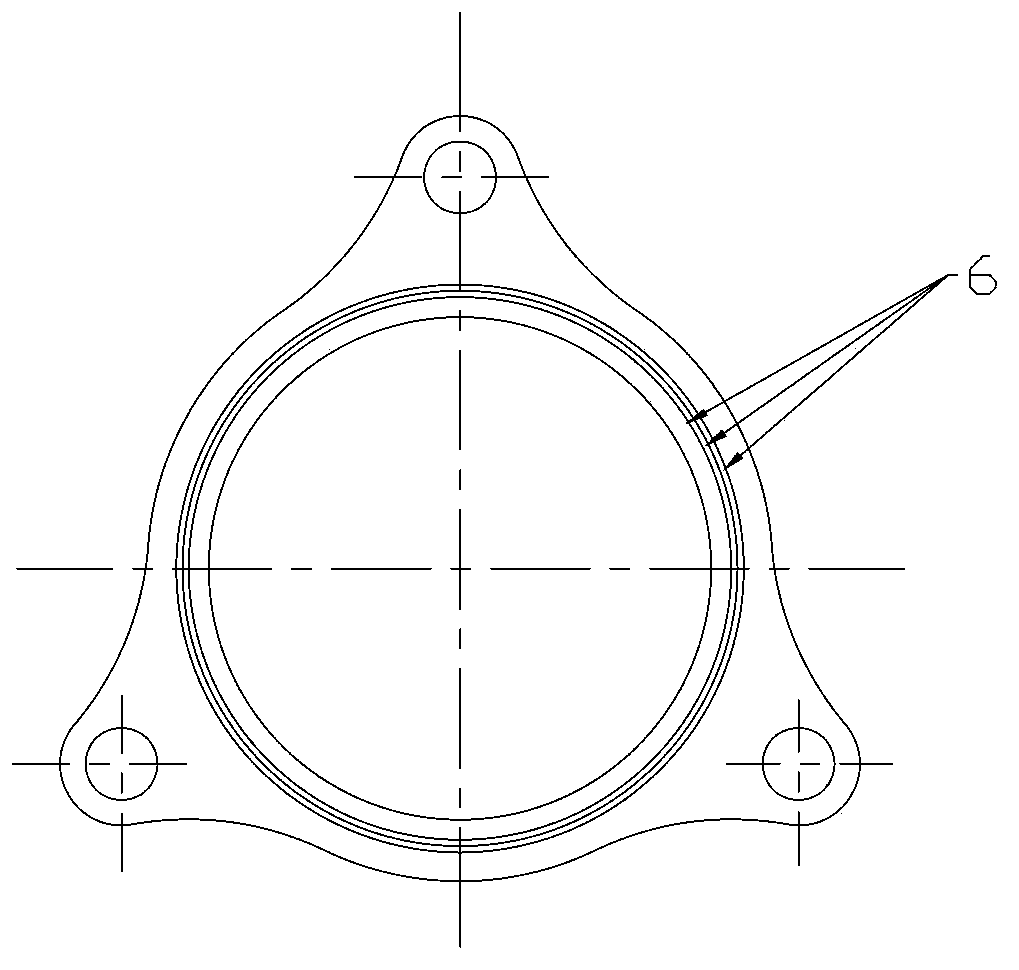

[0035] Such as Figure 5 , 6 As shown, in order to invent a gasket for the exhaust system of a supercharged engine, it includes a ring-shaped pressing block 2 and an elastic plate 1 embedded in the pressing block 2 along the circumferential direction of the pressing block 2; the The pressing block 2 has a degree of freedom of expansion and deformation along its thickness direction. in, Figure 5 The S direction in is the circumferential direction of the pressing block 2. In actual design, the elastic plate 1 can be embedded in the pressing block 2 along the circumference of the pressing block 2 in a circular, plane spiral or other path. The present invention can improve the stability of the structure of the pressing block 2 by utilizing the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com