Organic wastewater treatment method based on high-performance polyaniline aerogel

A technology for organic wastewater treatment and polyaniline, which is applied in the field of environmental treatment and can solve problems such as difficulty in separation, recovery and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

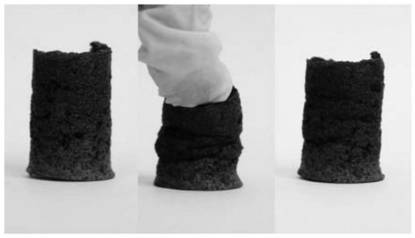

[0036] Mix 20mL of 0.1mmol / L iron salt solution and 2mL of aniline monomer, slowly add 1.2g of carboxylated cotton fiber under stirring, take it out after 10min and place it in a mold, freeze for 5h and then thaw to obtain a hydrogel. Weigh 26.6g of ferric nitrate nonahydrate according to the molar ratio of oxidant and aniline of 3:1, add it to 2.0mol / L nitric acid solution to dissolve, and soak the obtained hydrogel in the above solution for 24h to make aniline oxidatively polymerized. The polymerized hydrogel is washed with ethanol and deionized water to remove impurities such as oligomers, and finally freeze-dried to obtain polyaniline airgel. Such as figure 1 As shown, the obtained polyaniline airgel is a three-dimensional bulk material with certain compressive mechanical properties, and it can still fully recover its deformation after multiple compressions.

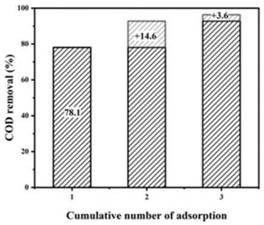

[0037] Take 80mg polyaniline airgel and put it into 20mL organic wastewater for adsorption. The COD removal rate ...

Embodiment 2-3

[0039] Ferric chloride hexahydrate and ferric sulfate hydrate were used instead of ferric nitrate nonahydrate in Example 1 as the iron salt to prepare a hydrogel, and other conditions were consistent with those in Example 1.

Embodiment 4

[0041] Mix 20mL of 0.1mmol / L iron salt solution with 2mL of aniline monomer, slowly add 1g of carboxylated bamboo fiber under stirring, take it out after 10min and place it in a mold, freeze for 10h and then thaw to obtain a hydrogel. Weigh 26.6g of ferric nitrate nonahydrate according to the molar ratio of oxidant and aniline of 3:1, add it to 2.0mol / L nitric acid solution to dissolve, and soak the obtained hydrogel in the above solution for 24h to make aniline oxidatively polymerized. The polymerized hydrogel is washed with ethanol and deionized water to remove impurities such as oligomers, and finally freeze-dried to obtain polyaniline airgel. Take 80mg of polyaniline airgel and put it into 20mL of organic wastewater for adsorption. After the adsorption is saturated, take out and place in 3mmol / L 2 o 2 In the solution for 30 minutes, the degradation of the organic adsorbate and the regeneration of the polyaniline airgel were realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com