Wear-resistant brake-shoe friction body for railway truck and brake-shoe

A friction body, truck technology, applied in the direction of friction lining, gear transmission mechanism, mechanical equipment, etc., can solve the problems of reducing wheel protection, compressive strength, bending strength, impact strength, shortening service life, etc., to achieve stable friction coefficient, low elastic modulus, high compressive strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

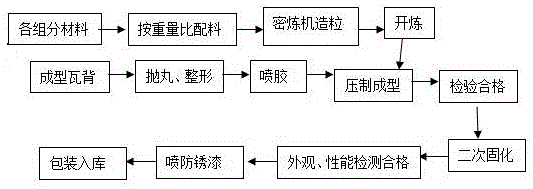

[0052] 1) Prepare and weigh the components of the friction body: 9% nitrile rubber, 5% cashew nut shell oil modified phenolic resin, 6% steel fiber, 16% sepiolite fiber, 12% composite fiber, 16% barium sulfate, 15% iron powder, 8% graphite, 6% feldspar powder, 2% calcined bauxite, 2% accelerator, 1% stearic acid, and 1% sulfur, meeting the requirement that the sum of the mass of each component reach 100%.

[0053] 2) Mixing and granulation: add the above-mentioned components into the internal mixer according to their mass percentages, except sulfur, and get the premixed material after internal mixing heating, pressurization, internal mixing adjustment, and crushing in the internal mixer The internal mixer is heated for 12 minutes and adjusted for 5 minutes. During the process, the temperature is controlled at 90 ° C. After cooling and crushing, the premix is obtained;

[0054] 3) Cool the premixed material after banburying to room temperature, weigh a certain weight and put ...

Embodiment 2

[0064] 1) Prepare and weigh the components of the friction body: 10% nitrile rubber, 6% cashew nut shell oil modified phenolic resin, 5% steel fiber, 18% sepiolite fiber, 11% composite fiber, 18% barium sulfate, 14% iron powder, 8% graphite, 6% feldspar powder, 1% calcined bauxite, 1% accelerator, 1% stearic acid, and 1% sulfur, meeting the requirement that the sum of the mass of each component reach 100%.

[0065] 2) Mixing and granulation: add the above-mentioned components into the internal mixer according to their mass percentages, except sulfur, and get the premixed material after internal mixing heating, pressurization, internal mixing adjustment, and crushing in the internal mixer The internal mixer is heated for 15 minutes and adjusted for 6 minutes. During the process, the temperature is controlled at 85 ° C. After cooling and crushing, the premix is obtained;

[0066] 3) Cool the premixed material after banburying to room temperature, weigh a certain weight and put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com