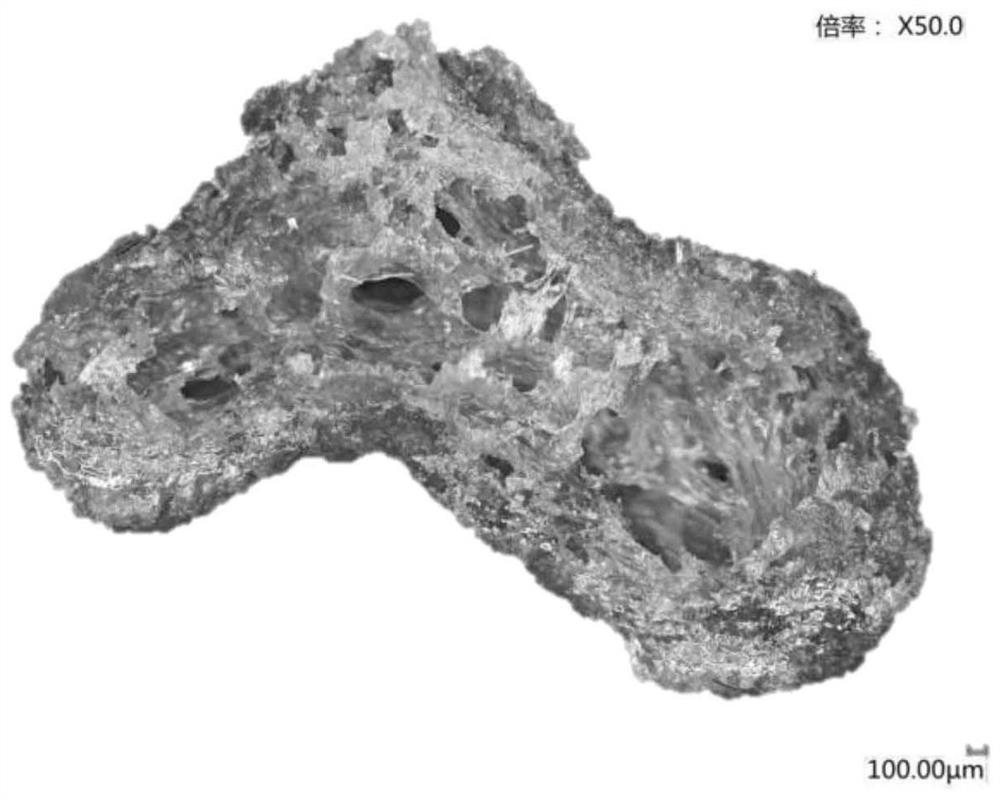

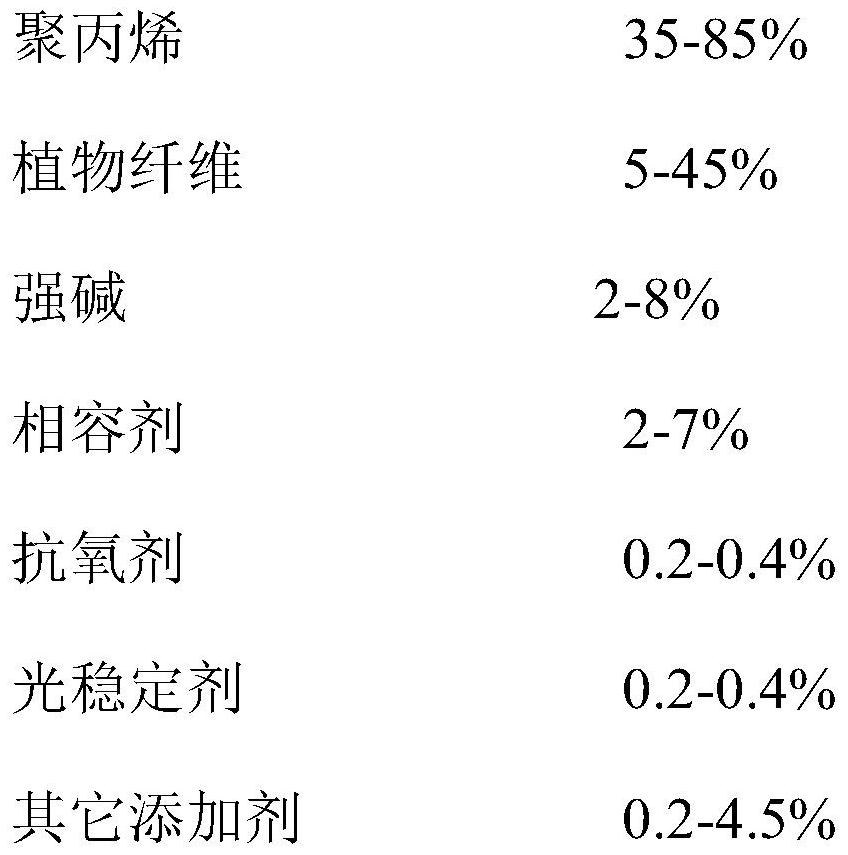

A kind of self-foaming plant fiber modified polypropylene material and preparation method thereof

A polypropylene material and plant fiber technology, which is applied in the field of self-foaming plant fiber modified polypropylene material and its preparation, can solve the problems of defective products, foaming agent decomposition speed blocks, small cells, etc., and achieve improved mechanical properties , The operation process is simple, the effect of uniform bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present application are further described below through specific embodiments. It should be understood by those skilled in the art that the embodiments are only for helping the understanding of the present application, and should not be regarded as a specific limitation of the present application.

[0034] Source of raw materials:

[0035] EP5175, LyondellBasell, polypropylene copolymer, melt index 3.5g / 10min (test condition 230℃, 2.16Kg);

[0036] 6012, Tianjin Zhongsha Petrochemical, homopolypropylene, melt index 11g / 10min (test condition 230℃, 2.16Kg);

[0037] Hemp fiber, Hangzhou Gaoke Composite Materials Co., Ltd., 5mm chopped hemp fiber;

[0038] Hemp fiber (pretreatment), Hangzhou Hi-Tech Composite Materials Co., Ltd. Hemp fiber was soaked in 7.5% sodium hydroxide aqueous solution for 12 hours, soaking temperature was 60°C, and then washed, dried and chopped, and the fiber length was 5mm;

[0039] Bamboo fiber, Hangzhou Gaoke Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com