Microporous polymer carrier as well as preparation method and application thereof

A microporous polymer and carrier technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor adsorption efficiency, low processing efficiency, and uncontrollable opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

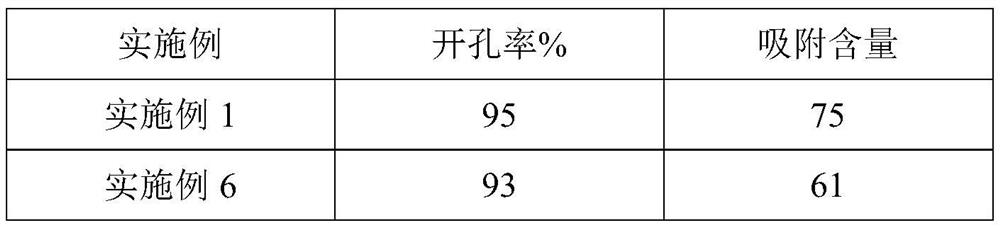

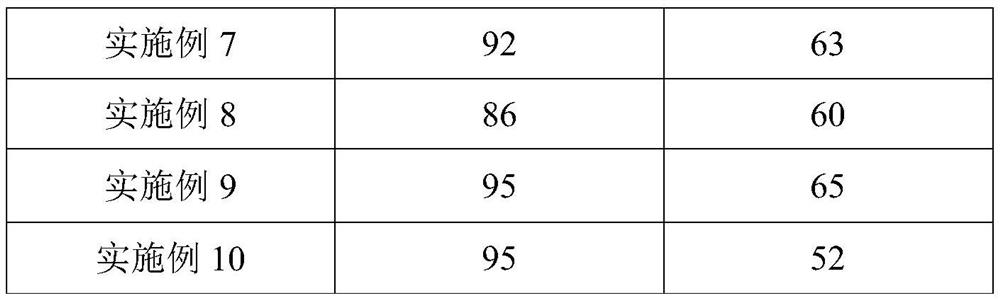

Examples

preparation example Construction

[0046] The second aspect of the present invention provides a method for preparing the microporous polymer carrier. The steps at least include: mixing polyolefin resin, modifier, and nucleating agent into an extruder, and extruding The foaming agent is injected into the compression section of the machine, extruded and granulated, and the product is obtained.

[0047] In some preferred embodiments, the preparation method of the microporous polymer carrier includes at least the following steps: mixing the polyolefin resin, modifier, and nucleating agent uniformly through a mixer, adding them to the feeding port of the extruder, and The foaming agent is injected into the compression section of the extruder, extruded, stretched, cooled, and granulated, and the product is obtained.

[0048] In some embodiments, the aspect ratio of the microporous polymer carrier is 0.1-2.5, and the length is 3-10 mm; preferably, the aspect ratio of the microporous polymer carrier is 0.1-1, and the l...

Embodiment 1

[0052] A kind of microporous polymer carrier, by weight, raw material is: polyolefin resin 120 parts, modifier 15 parts, nucleating agent 3 parts; Said raw material also includes foaming agent, the addition of said foaming agent The amount is 18% of the polyolefin resin mass.

[0053] The polyolefin resin is selected from the combination of polypropylene, ethylene / acrylate copolymer and polyamide resin. The weight ratio of the polypropylene, ethylene / acrylate copolymer and polyamide resin is 1:0.15:0.1. The melt flow index of the polypropylene random copolymer is 9 g / 10 min, purchased from PP (polypropylene) 599RCXP / Iran JPC. The ethylene / acrylate copolymer is ethylene-butyl acrylate copolymer. The melt flow index of the ethylene-butyl acrylate copolymer is 1.5 g / 10 min, purchased from EBA (ethylene-butyl acrylate copolymer) AC 3135 / DowDuPont. The polyamide resin is non-ionic polyacrylamide purchased from Henan Debang Water Treatment Materials Co., Ltd.

[0054] The blowin...

Embodiment 2

[0059] A kind of microporous polymer carrier, by weight, raw material is: polyolefin resin 100 parts, modifier 5 parts, nucleating agent 1 part; Said raw material also includes foaming agent, the addition of said foaming agent The amount is 10% of the polyolefin resin mass.

[0060] The polyolefin resin is selected from the combination of polypropylene, ethylene / acrylate copolymer and polyamide resin. The weight ratio of the polypropylene, ethylene / acrylate copolymer and polyamide resin is 1:0.05:0.01. The polypropylene random copolymer has a melt flow index of 7 g / 10 min, purchased from PP (polypropylene) PCC0742 / Braskem, Brazil. The ethylene / acrylate copolymer is ethylene-butyl acrylate copolymer. The melt flow index of the ethylene-butyl acrylate copolymer is 0.6g / 10min, purchased from EBA (ethylene-butyl acrylate copolymer) FA4088 / Austria Borealis. The polyamide resin is non-ionic polyacrylamide purchased from Henan Debang Water Treatment Materials Co., Ltd.

[0061] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com