Environment-friendly polyurethane prepolymer and preparation method thereof

A polyurethane prepolymer, environmentally friendly technology, applied in the field of fine chemicals, can solve the problem of high free isocyanate content, achieve the effects of high shear strength, reduced release and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

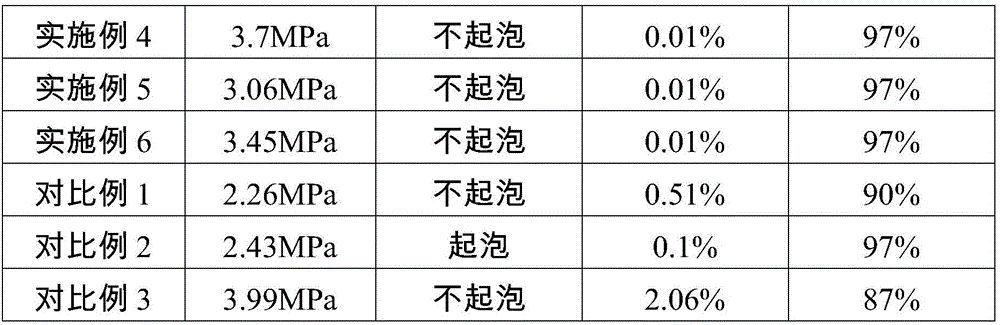

Examples

Embodiment 1

[0042] Weigh 100 parts of polypropylene carbonate diol, add it into a glass reactor with a vacuum device, vacuum dehydrate at 100°C for 2 hours, add 0.04 parts of phosphoric acid, 0.04 parts of stannous octoate, 70 parts of liquefied MDI, and heat at 80°C React for 2 hours, lower the temperature to 40°C, add KH540, and react for 1 hour to obtain a siloxane-modified polyurethane prepolymer.

Embodiment 2

[0044] Weigh 100 parts of polypropylene carbonate diol, add it into a glass reactor with a vacuum device, vacuum dehydrate at 100°C for 2 hours, add 0.18 parts of phosphoric acid, 0.04 parts of stannous octoate, 39 parts of liquefied MDI, and heat at 80°C React for 2 hours, lower the temperature to 40°C, add 10 parts of KH540, and react for 1 hour to obtain a siloxane-modified polyurethane prepolymer.

Embodiment 3

[0046]Weigh 100 parts of polypropylene carbonate diol, add it into a glass reactor with a vacuum device, vacuum dehydrate at 100°C for 2 hours, add 0.08 parts of phosphoric acid, 0.04 parts of stannous octoate, 39 parts of liquefied MDI, and heat at 70°C React for 4 hours, lower the temperature to 20°C, add 3 parts of KH540, and react for 1.5 hours to obtain a siloxane-modified polyurethane prepolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com