Natural tea saponin foaming agent and preparation method thereof

A technology of tea saponin and foaming agent, applied in the field of natural tea saponin foaming agent and its preparation, can solve the problems of affecting foaming stability, poor foaming stability, easy deterioration and degradation of tea saponin, etc. Stable and reliable foaming performance, stable foaming, simple and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation of embodiment 1 natural tea saponin whipping agent

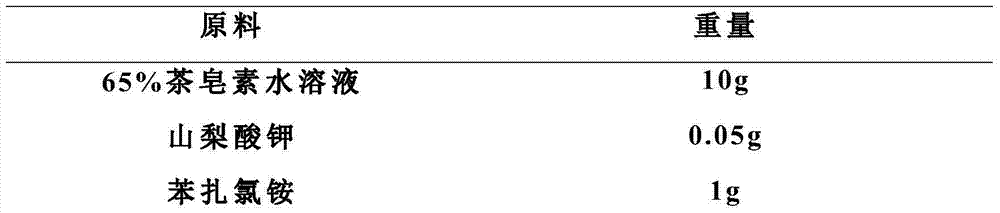

[0055] The raw material formula that present embodiment adopts is as follows (formula 1):

[0056] The raw material formula of table 1 embodiment 1 natural tea saponin whipping agent

[0057]

[0058]

[0059] Concrete preparation steps:

[0060] Take 10g of 65% tea saponin aqueous solution in a small beaker, add 0.05g potassium sorbate, 1g benzalkonium chloride, 0.8g n-butanol, and mix well.

Embodiment 2

[0061] The preparation of embodiment 2 natural tea saponin whipping agent

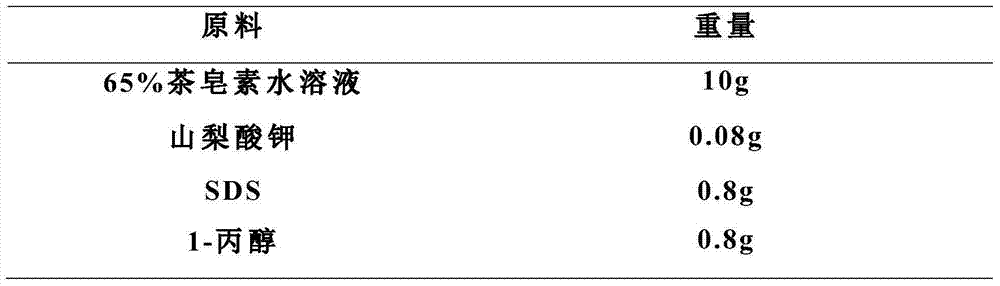

[0062] The raw material formula that present embodiment adopts is as follows (formula 2):

[0063] The raw material formula of table 2 embodiment 2 natural tea saponin foaming agents

[0064]

[0065] Concrete preparation steps:

[0066] Take 10g of tea saponin aqueous solution with a mass percentage concentration of 65% in a small beaker, add 0.08g of potassium sorbate, 0.8g of SDS, and then add 0.8g of 1-propanol, and mix well.

Embodiment 3

[0067] The preparation of embodiment 3 natural tea saponin whipping agent

[0068] The raw material formula that present embodiment adopts is as follows (recipe 3):

[0069] The raw material formula of table 3 embodiment 3 natural tea saponin foaming agents

[0070]

[0071] Concrete preparation steps:

[0072] Take 10 g of tea saponin aqueous solution with a concentration of 65% by mass in a small beaker, add 0.1 g of butylparaben, 1.2 g of SDS and 1 g of 1-dodecyl alcohol, and mix well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com