Intelligent electric induction decondensation system of condensation pipeline

A smart electricity and pipeline technology, applied in pipeline heating/cooling, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as liquid medium is easy to freeze, high cost, and the number of power supply points increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

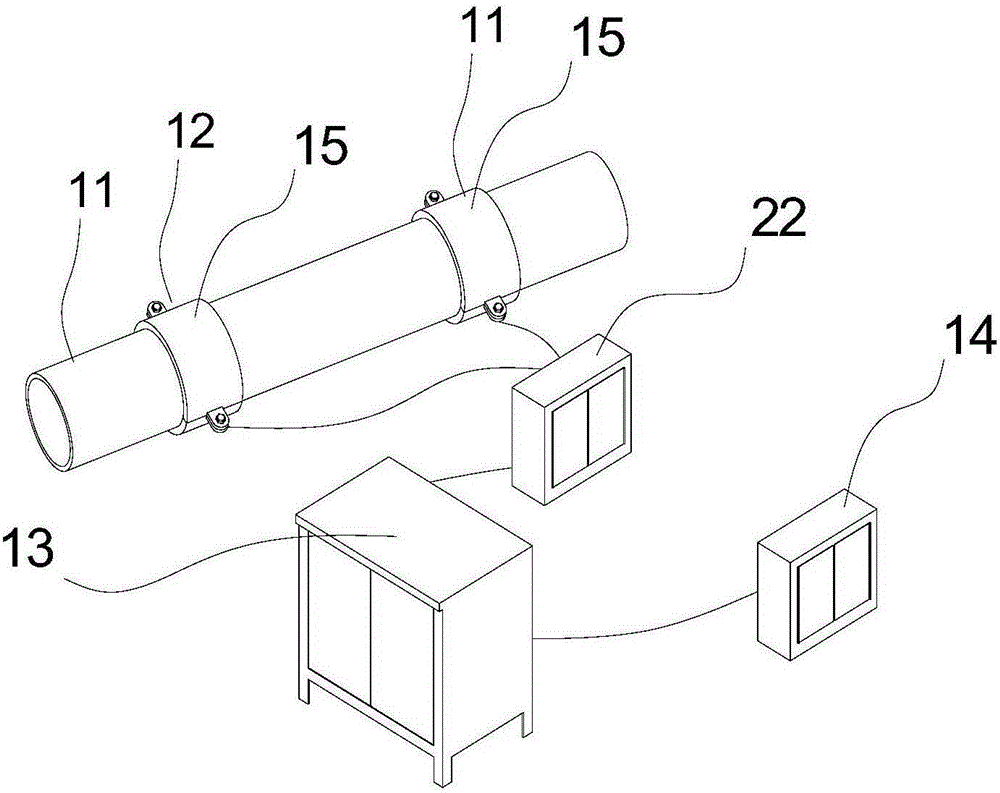

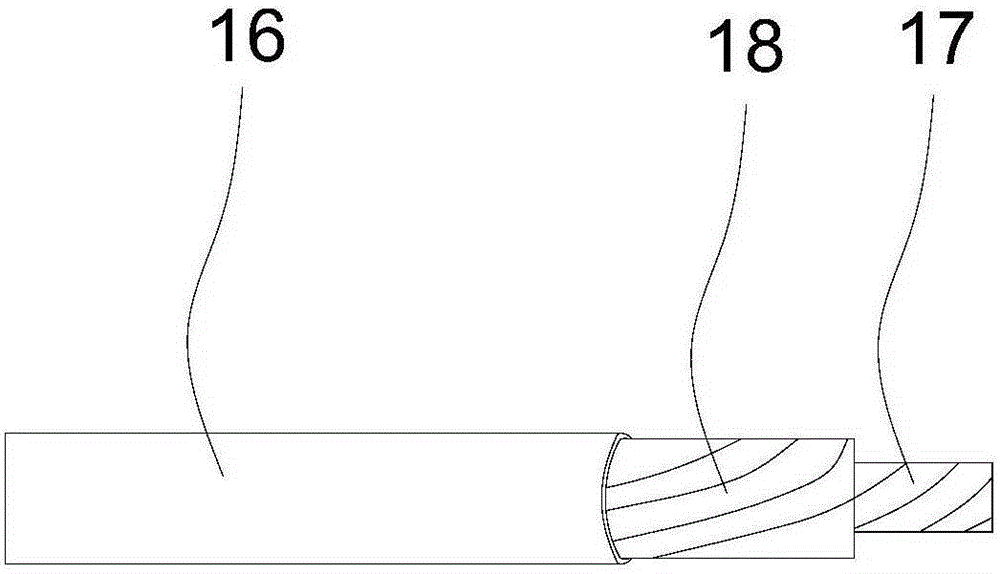

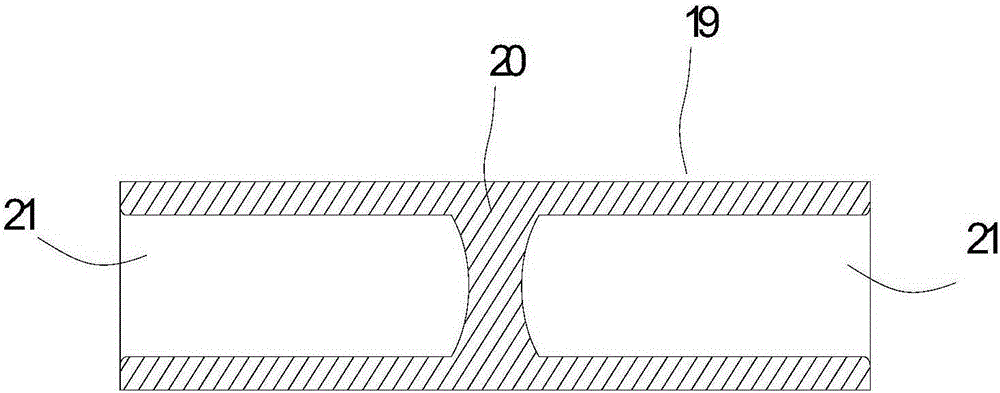

[0044] refer to figure 1 , the present invention provides an intelligent electric induction decondensation system for condensation pipes, comprising: a heating device 12, a control device 13, and a power supply device 14; the heating device 12 includes a condensation pipe 11;

[0045] The heating device 12 is used to utilize the heat energy generated by the alternating current flowing through the coagulation pipeline 11, and combine the skin effect to heat the coagulation pipeline 11;

[0046] The control device 13, when the decondensation system is powered on, generates a control signal according to the received control command to control the working state of the heating device 12;

[0047] The power supply device 14 is used to supply power to the heating device 12 and the control device 13 .

[0048] The intelligent electric induction decondensation system of the condensation pipeline provided by the embodiment of the present invention adopts the heating device 12 to use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com