Mining water base foam preventing coal spontaneous combustion and manufacturing method thereof

A coal spontaneous combustion, water-based technology, used in mining equipment, dust prevention, earthwork drilling and other directions, can solve the problem that the performance of water-based foam cannot meet the performance requirements of foam materials, the foaming ratio of water-based foam is low, and the stabilization time is short, etc. problem, to achieve the effect of convenient production, high foaming ratio and long stability time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

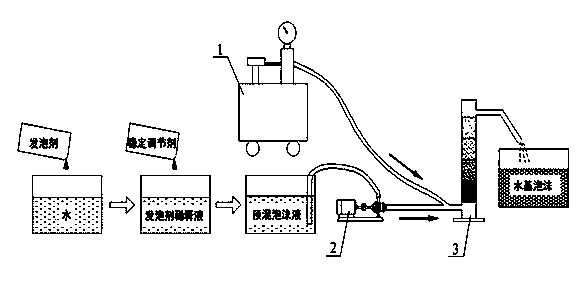

[0024] like figure 1 Shown, the preparation method of the water-based foam of a kind of mine prevention and control coal spontaneous combustion of the present invention, comprises the following steps:

[0025] (1) Add 10-20 parts of sodium lauryl sulfate and 0.5-4 parts of bovine hoof horn hydrolyzate to 70-80 parts of water, and stir to form a surfactant dilution;

[0026] (2) Add 1-2 parts of hydroxypropyl methylcellulose, 2-4 parts of dodecanol, 1-2 parts of cationic guar gum, 0.1-0.5 parts of Polystyrene-acrylic latex particles, 0.5-2 parts of sodium chloride, and stirring to form a premixed foam;

[0027] (3) By stuffing steel balls, metal screens or glass microspheres in the cavity of the foamer, and from the raw material inlet to the water-based foam outlet, the porosity of the filling medium increases step by step to form the required porous foam 3, and then through the air compressor 1, pass compressed air with a pressure of 100-200kPa into the porous foamer 3, and ...

Embodiment 1

[0029] A kind of water-based foam for preventing and controlling coal spontaneous combustion for mining, the water-based foam is prepared according to the following steps in parts by weight:

[0030] (1) Add a foaming agent consisting of 10 parts of sodium lauryl sulfate and 4 parts of cow's hoof horn hydrolyzate to 80 parts of water, and fully stir to form a surfactant dilution;

[0031] (2) Add 1.5 parts of hydroxypropyl methylcellulose, 2 parts of dodecyl alcohol, 1 part of cationic guar gum, and 0.5 parts of polystyrene-acrylic latex particles to the dilution of step (1). (particle size of 10 μm) and 0.5 parts of sodium chloride as a stabilizer, and stirred to form a premixed foam;

[0032] (3) By stuffing steel balls in the cavity of the foamer, and from the raw material inlet to the outlet of the water-based foam, the porosity of the filling medium increases step by step to make the required porous foamer 3, the porous foamer The compressed air inlet of 3 and the premix...

Embodiment 2

[0034] A kind of water-based foam for preventing and controlling coal spontaneous combustion for mining, the water-based foam is prepared according to the following steps in parts by weight:

[0035] (1) Add a foaming agent consisting of 12 parts of sodium lauryl sulfate and 3 parts of cow's hoof horn hydrolyzate to 78 parts of water, and fully stir to form a surfactant dilution;

[0036] (2) Add 2 parts of hydroxypropyl methylcellulose, 2.5 parts of dodecanol, 1 part of cationic guar gum, and 0.3 parts of polystyrene-acrylic latex particles to the dilution of step (1). (particle size of 10 μm) and 1.2 parts of sodium chloride as a stabilizer, and stirred to form a premixed foam;

[0037](3) By stuffing steel balls in the cavity of the foamer, and from the raw material inlet to the outlet of the water-based foam, the porosity of the filling medium increases step by step to make the required porous foamer 3, the porous foamer The compressed air inlet of 3 and the premixed foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com