Camptothecin medicament injection solution and injection and preparation method thereof

A technology of camptothecin and injections, which is applied in the field of medicine, can solve problems such as difficulty in making injections, and achieve the effects of improving safety and effectiveness, improving stability, and increasing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

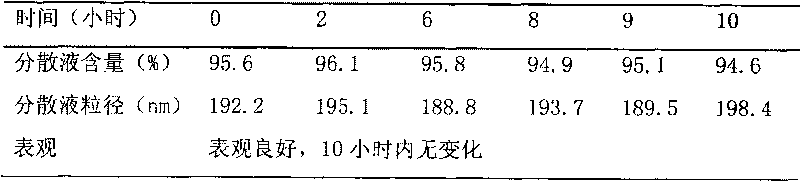

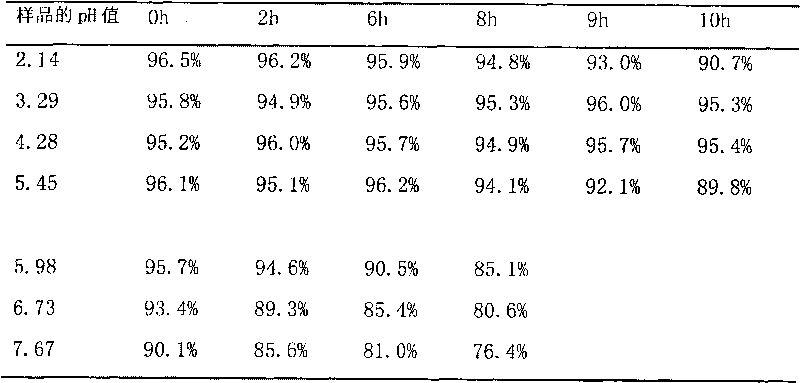

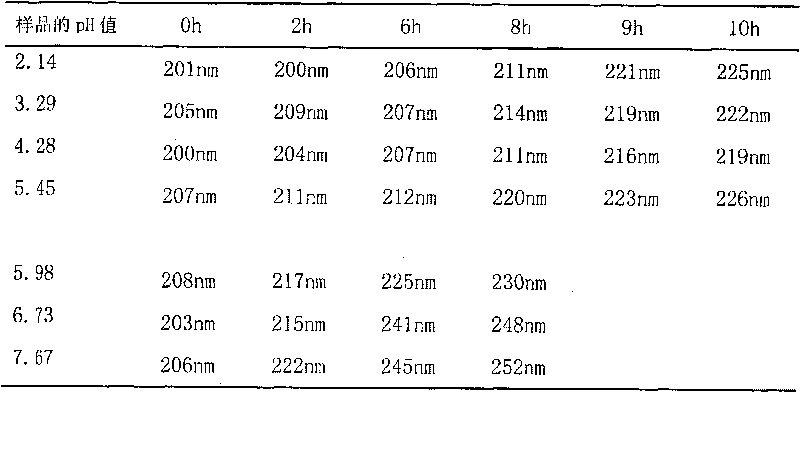

[0055] Embodiment 1 prepares 10-hydroxycamptothecin injection solution and injection thereof

[0056] 1. Preparation of 10-hydroxycamptothecin injection solution

[0057] Weigh 1.0 g of 10-hydroxycamptothecin and 0.0005 g of disodium edetate, add it to an appropriate amount of polyethylene glycol 400, stir and dissolve at 40°C, and then dilute to 100 ml with polyethylene glycol 400 ; use citric acid to adjust the pH value to 4.15; add 0.50 grams of activated carbon for needles, absorb at a temperature of 30 ° C for 25 minutes, then filter with a 0.22 μm microporous membrane, pack in plastic or glass bottles, seal, Sterilize with circulating steam at 100°C for 30 minutes, and store for future use. Keep away from light during the whole preparation process.

[0058] 2. Preparation of Emulsion for Injection

[0059] Take 100 grams of caprylic triglyceride for injection and 100 grams of soybean oil, heat it in a water bath to 75°C, add 12 grams of egg yolk phospholipids for inje...

Embodiment 2

[0066] Embodiment 2 prepares 10-hydroxycamptothecin injection solution and injection thereof

[0067] 1. Preparation of 10-hydroxycamptothecin injection solution

[0068] Take 1.1 g of 10-hydroxycamptothecin, add it to an appropriate amount of polyethylene glycol 400, stir and dissolve at 35 ° C, and then use polyethylene glycol 400 to make the volume to 100 ml; adjust the pH value to 4.28 with citric acid; add 0.2 g of activated carbon for needles, adsorbed at 25°C for 35 minutes, then filtered with a 0.22 μm microporous membrane, packed in plastic or glass bottles, sealed, and sterilized in a rotary autoclave at 115°C for 20 minutes , store for later use. Keep away from light during the whole preparation process.

[0069] 2. Preparation of Emulsion for Injection

[0070] Take 200 grams of soybean oil for injection, heat it to 75°C in a water bath, add 12 grams of egg yolk phospholipids for injection, stir to dissolve to obtain an oil phase; take 700 ml of water for inject...

Embodiment 3

[0075] Embodiment 3 prepares 10-hydroxycamptothecin injection solution and injection thereof

[0076] 1. Preparation of 10-hydroxycamptothecin injection solution

[0077] Take 0.7 g of 10-hydroxycamptothecin and 0.01 g of vitamin E, add it to an appropriate amount of polyethylene glycol 400, stir and dissolve at 45 ° C, then use polyethylene glycol 400 to make the volume to 100 ml; adjust the pH with citric acid value to 3.95; add 0.8 g of activated carbon for needles, absorb at 45°C for 60 minutes, then filter with a 0.22 μm microporous membrane, pack in plastic or glass bottles, seal, and sterilize at 121°C for 15 minutes. Store for later use. Keep away from light during the whole preparation process.

[0078] 2. Preparation of Emulsion for Injection

[0079] Take 50 grams of soybean oil and 50 grams of caprylic triglyceride, mix them, heat in a water bath to 60°C, add 12 grams of egg yolk phospholipids for injection, cut and dissolve to obtain an oil phase; take 800 ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com