Polyurethane foam material for packaging and preparation method thereof

A technology of polyurethane foam and foam stabilizer, applied in the field of chemical materials, can solve the problems of fixed material density, insufficient elasticity of foam plastic, white pollution, etc., and achieve the effects of stable product quality, stable foaming process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

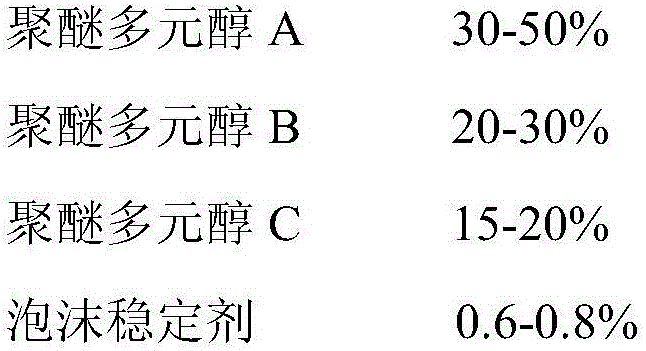

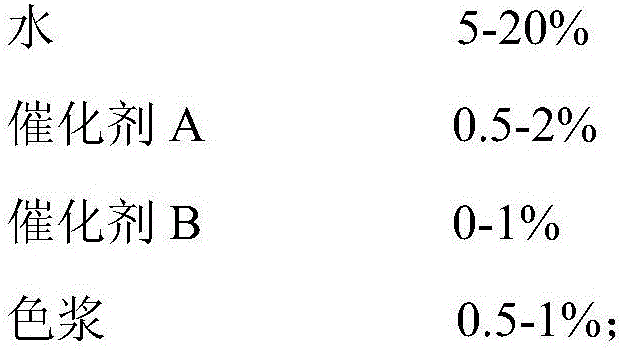

Method used

Image

Examples

Embodiment 1

[0027] (1) Prepare A component: 100kg, weigh YEP-330N, 50kg, YNW-8345, 21kg, YNW-310, 20kg, L-6868, 0.8kg, water, 5kg, A-1, 1kg, A- 33. 0.7kg, potassium isooctanoate, 0.5kg, color paste, 1kg. Add the weighed polyether polyol A, polyether polyol B, polyether polyol C, foam stabilizer, water, catalyst A, catalyst B, and color paste into the reaction kettle in sequence, and stir at room temperature for 2 hours , after the sampling test is qualified, it can be loaded into barrels.

[0028] (2) Component B: polymethyl polyphenyl polyisocyanate, 100kg, weighed for future use.

[0029] (3) Component A and component B were poured into the mold through a pouring machine at a weight ratio of 100:100, and then formed and matured to obtain a product. The performance indicators of the tested product are shown in Table 1.

Embodiment 2

[0031] (1) Prepare A component: 100kg, respectively weigh YEP-330N, 40kg, YNW-8345, 28kg, YNW-305, 20kg, L-580, 0.3kg, L-6868, 0.3kg, water, 8kg, A -1, 1.3kg, A-33, 0.6kg, potassium isooctanoate, 1kg, color paste, 0.5kg. Add the weighed polyether polyol A, polyether polyol B, polyether polyol C, foam stabilizer, water, catalyst A, catalyst B, and color paste into the reaction kettle in sequence, and stir at room temperature for 2 hours , after the sampling test is qualified, it can be loaded into barrels.

[0032] (2) Component B: polymethyl polyphenyl polyisocyanate, 100kg, weighed for future use.

[0033] (3) Mix component A and component B in a weight ratio of 100:100, mix them evenly with a hand drill, inject them into the cavity of the object to be packaged, and form and mature the product to obtain the product. The performance indicators of the tested product are shown in Table 1 .

Embodiment 3

[0035] (1) Prepare A component: 100kg, weigh YEP-330N, 36kg, YNW-8345, 25kg, YNW-305, 15kg, L-580, 0.8kg, water, 20kg, A-1, 1.1kg, A -33, 0.5kg, potassium isooctanoate, 0.8kg, color paste, 0.8kg. Add the weighed polyether polyol A, polyether polyol B, polyether polyol C, foam stabilizer, water, catalyst A, catalyst B, and color paste into the reaction kettle in sequence, and stir at room temperature for 2 hours , after the sampling test is qualified, it can be loaded into barrels.

[0036] (2) Component B: polymethyl polyphenyl polyisocyanate, 100kg, weighed for future use.

[0037] (3) Component A and component B were poured into the mold through a pouring machine at a weight ratio of 100:100, and then formed and matured to obtain a product. The performance indicators of the tested product are shown in Table 1.

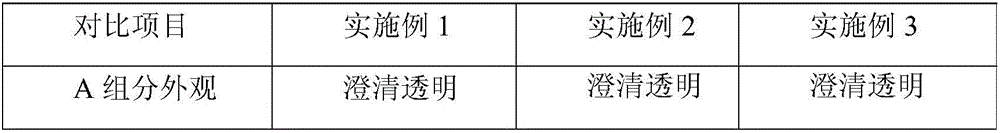

[0038] The basic performance index of the product that table 1 embodiment 1-3 makes

[0039]

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com