Active carbon fiber three-dimensional particle electrode catalyst and preparation method thereof

A technology of activated carbon fibers and particle electrodes, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of high cost of diamond thin film electrodes, undiscovered, and low service life of tin dioxide electrodes. Achieve the effects of low production cost, high adsorption or desorption rate, and strong oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

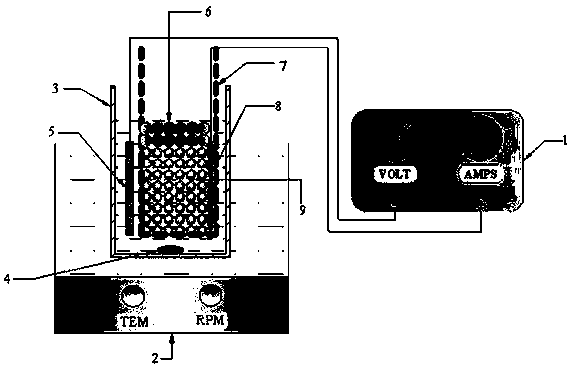

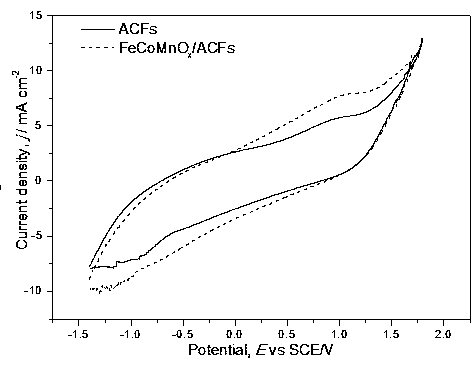

[0032] A three-dimensional electrode, the anode of the electrode is a ruthenium-titanium electrode, the cathode is a stainless steel electrode, and the particle electrode is located between the cathode and anode electrodes; the particle electrode uses activated activated carbon fibers as a carrier, and the carrier is loaded with Fe, Co, The four metals Mn and Sn correspond to catalysts in oxides.

[0033] The weight of the catalyst loaded on the activated activated carbon fiber is 1% of the activated carbon fiber.

[0034] The preparation method of the three-dimensional particle electrode loaded with catalyst activated carbon fiber includes the following steps.

[0035] 1) Fe, Co, Mn nitrate, SnCl 2 Dissolve in deionized water to obtain the corresponding impregnating solution, the concentration of metal cations in the impregnating solution is 0.5 mol / L.

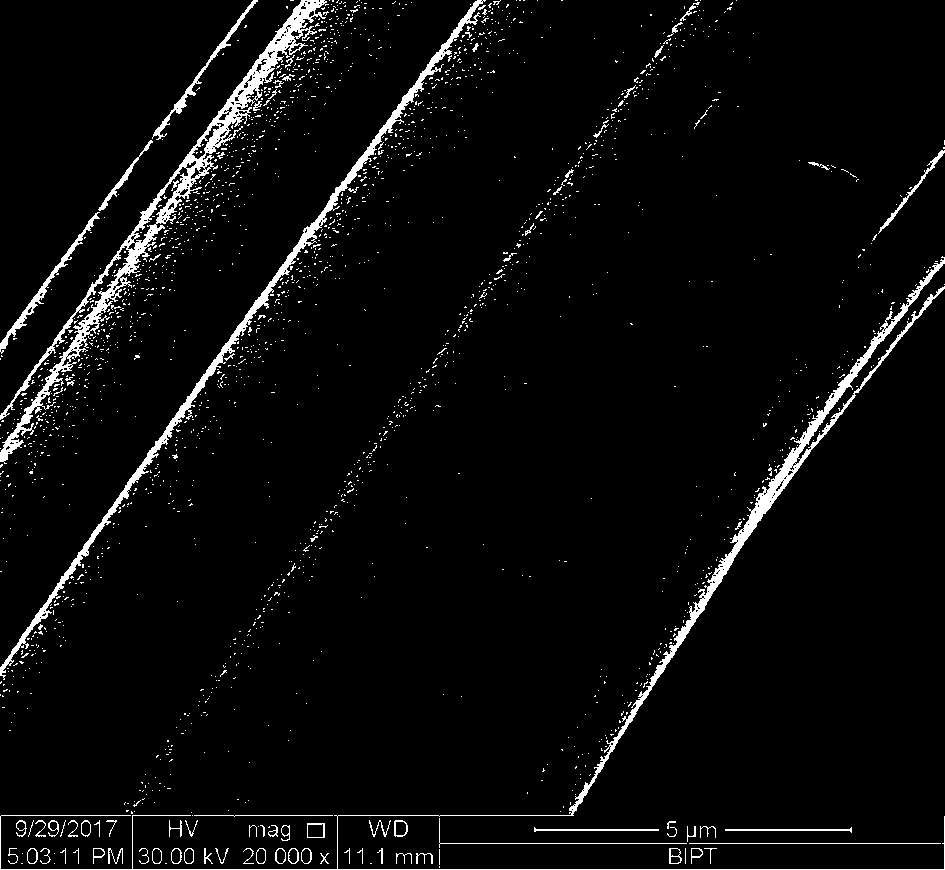

[0036]2) Cut the activated carbon fiber into a sheet material with a size of 10 × 10 mm, wash it thoroughly with deionize...

Embodiment 2

[0041] A three-dimensional electrode, the anode of the electrode is a ruthenium-titanium electrode, the cathode is a stainless steel electrode, and the particle electrode is located between the cathode and anode electrodes; the particle electrode uses activated activated carbon fibers as a carrier, and the carrier is loaded with Fe, Co, The three metals of Mn correspond to catalysts in oxides.

[0042] The weight of the catalyst loaded on the activated activated carbon fiber was 9% of the activated carbon fiber.

[0043] The preparation method of the three-dimensional particle electrode loaded with catalyst activated carbon fiber includes the following steps.

[0044] 1) Dissolve the nitrates of Fe, Co, and Mn in deionized water first to obtain the corresponding impregnation solution. The concentration of metal cations in the impregnation solution is 1mol / L.

[0045] 2) Cut the activated carbon fibers into sheet-like materials with a size of 10 × 10 mm, wash them thoroughly w...

Embodiment 3

[0050] A three-dimensional electrode, the anode of the electrode is a ruthenium-titanium electrode, the cathode is a stainless steel electrode, and the particle electrode is located between the cathode and anode electrodes; the particle electrode uses activated activated carbon fiber as a carrier, and the carrier is loaded with Fe and Co. The metal corresponds to the catalyst in the oxide.

[0051] The weight of the catalyst loaded on the activated activated carbon fiber is 5% of the activated carbon fiber.

[0052] The preparation method of the three-dimensional particle electrode loaded with catalyst activated carbon fiber includes the following steps.

[0053] 1) Dissolve the nitrates of Fe and Co in deionized water first to obtain the corresponding impregnating solution. The concentration of metal cations in the impregnating solution is 0.7mol / L.

[0054] 2) Cut the activated carbon fiber into a sheet material with a size of 10 × 10 mm, wash it thoroughly with deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com