Preparation method of foaming stainless steel plate, and preparation method of heat-engine plant denitration catalyst

A technology of denitrification catalyst and stainless steel plate, applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instrument and method, etc., can solve the problems of poor binding force of titanium colloid coating, poor anti-clogging performance, poor catalytic activity, etc. Achieve the effects of improving the microporous structure and specific surface area, good anti-clogging performance, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

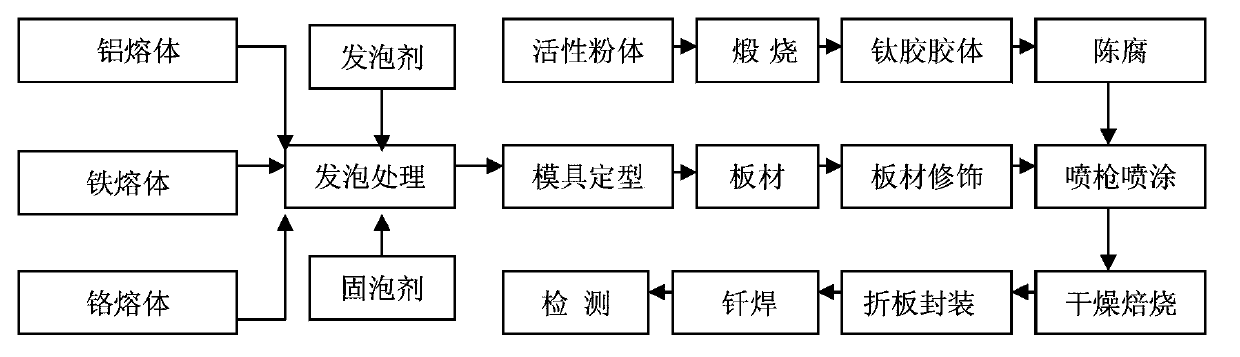

[0045] The preparation method of foamed stainless steel sheet adopts 5% (mass ratio) hydride foaming agent, mixes with aluminum melt, iron melt and chromium melt, adds hydride foaming agent, and adds the hydride foaming agent at a temperature of 500-1500r / min. Stir at a high speed at high speed, add 10% (mass ratio) polyvinyl alcohol as a solid foaming agent during the stirring process, pour it into the corresponding mold after stirring evenly, and enter the foaming machine for foaming. The foaming temperature is 540 ~ 650 ℃, The foaming time is 1-10min. After the foaming, the plate is taken out for cutting and modification to obtain the foamed stainless steel plate of the required specifications and requirements. The distance between the plates is 5-15mm, and the distance between the peaks of the folding plates is 30-70mm. This method Compared with the traditional catalyst, the prepared catalyst has larger open pore area and anti-ash blocking performance.

[0046] According t...

Embodiment 1

[0055] Preparation of foamed stainless steel plate:

[0056] Titanium hydride and polyvinyl alcohol are added to the iron-chromium-aluminum alloy melt, wherein, titanium hydride is used as a foaming agent, and polyvinyl alcohol is used as a solid foaming agent, and the addition of the hydride foaming agent is 5% by weight of the aluminum alloy, The amount of polyvinyl alcohol added is 0.5% of the weight of the aluminum alloy, and then the melt is stirred at a speed of 500r / min. After stirring evenly, the melt is poured into the cuboid cavity in the mold, and then the mold is put into the foaming machine. In the process, the melt was foamed at a temperature of 400 °C for 1 min. After the foaming treatment was completed, the plate was taken out from the mold cavity to obtain a foamed stainless steel plate.

[0057] Taking the above-mentioned foamed stainless steel plate as a carrier to prepare a thermal power plant denitration catalyst:

[0058] Step 1: Preparation of Titanium ...

Embodiment 2

[0070] Preparation of foamed stainless steel plate:

[0071] Titanium hydride and polyvinyl alcohol are added to the iron-chromium aluminum alloy melt, wherein, titanium hydride is used as a foaming agent, and polyvinyl alcohol is used as a solid foaming agent, and the addition of the hydride foaming agent is 7% by weight of the aluminum alloy, The amount of polyvinyl alcohol added is 3% of the weight of the aluminum alloy, and then the melt is stirred at a speed of 1000r / min. After stirring evenly, the melt is poured into the cuboid cavity in the mold, and then the mold is put into the foaming machine. In the process, the melt was foamed at a temperature of 550 °C for 5 min. After the foaming treatment, the plate was taken out from the mold cavity to obtain a foamed stainless steel plate.

[0072] Taking the above-mentioned foamed stainless steel plate as a carrier to prepare a thermal power plant denitration catalyst:

[0073] Step 1: Preparation of Titanium Colloid:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com