Ultrafine diamond coated diaphragm and lithium ion battery using diaphragm

A separator and diamond technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as defects, ceramic separators falling off surfaces, etc., to inhibit the generation of lithium crystal dendrites, inhibit lithium ion aggregation, and increase safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

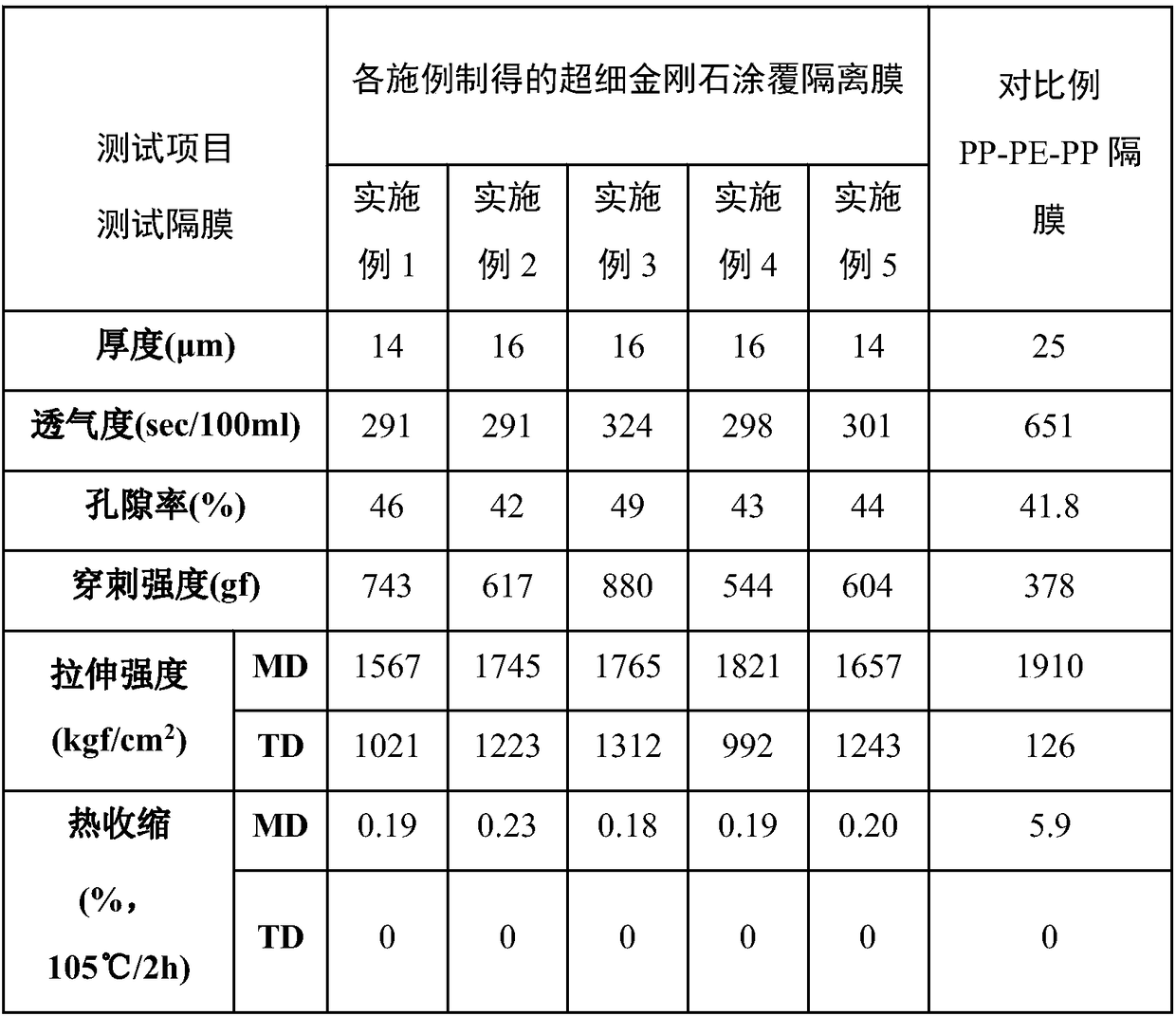

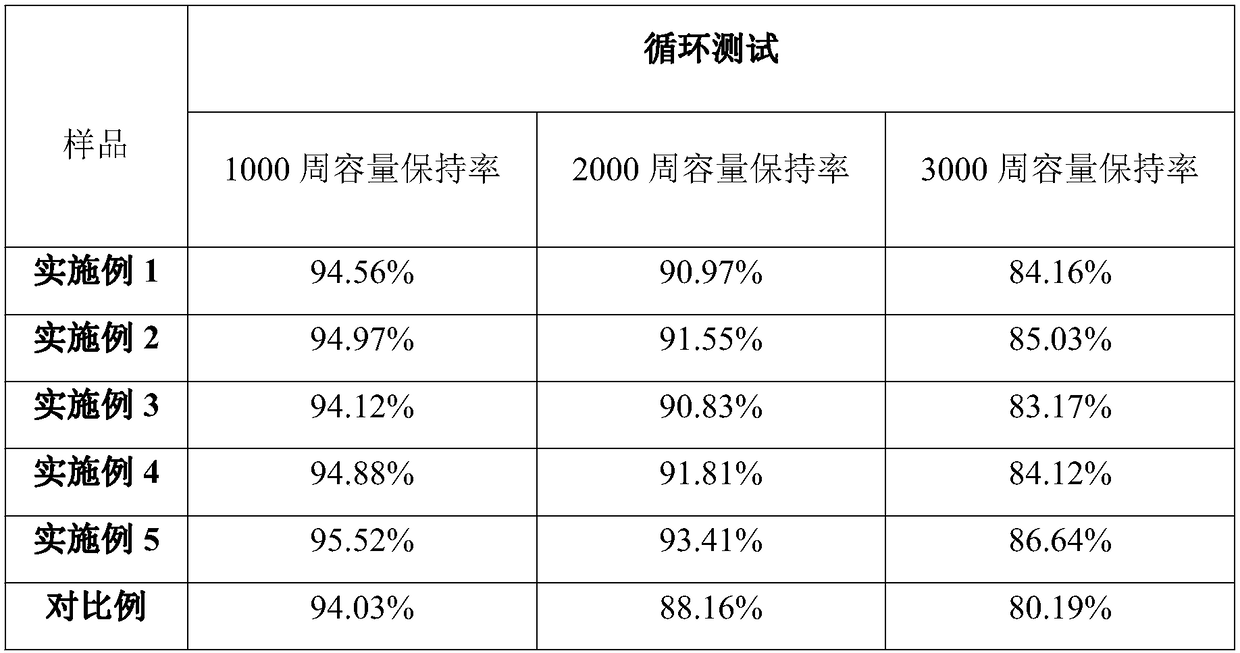

Embodiment 1

[0036] A method for preparing an ultrafine diamond-coated isolation film, comprising the steps of:

[0037] (1) Weigh each raw material in the solid component in the slurry, and the mass percentage of each component is in brackets

[0038] Ultrafine diamond powder and inorganic filler 10.16kg (66%);

[0039] (5.08kg of ultrafine diamond powder, 5.08kg of inorganic filler, the quality of ultrafine diamond powder is 50% of the total mass of ultrafine diamond powder and inorganic filler.)

[0040] Filler CMC 3.70kg (24%);

[0041] Glue SBR 1.54kg (10%);

[0042] Measure 5.08kg of ultra-fine diamond powder, 5.08kg of inorganic filler and 3.70kg of CMC, first stir slowly for 15 minutes, scrape the bottom and scrape the wall, then stir quickly for 60 minutes, and mix well; add 40kg of deionized water, stir slowly for 15 minutes, After scraping the bottom and wall, stir quickly for 60 minutes, and mix well; add 1.54kg of styrene-butadiene rubber SBR, stir for 15 minutes at a slow ...

Embodiment 2

[0046] A method for preparing an ultrafine diamond-coated isolation film, comprising the steps of:

[0047] (1) Weigh each raw material in the solid component in the slurry, and the mass percentage of each component is in brackets

[0048] Ultrafine diamond powder and inorganic filler 9.80kg (70%),

[0049] (0.98kg of ultrafine diamond powder, 8.82kg of inorganic filler, the quality of ultrafine diamond powder is 10% of the total mass of ultrafine diamond powder and inorganic filler.)

[0050] Filler CMC 2.8kg (20%),

[0051] Glue SBR 1.4kg (10%);

[0052] Measure 7.82kg of alumina powder, 1kg of boehmite powder, 0.98kg of ultra-fine diamond powder and 2.8kg of CMC, first stir slowly for 15 minutes, scrape the bottom and scrape the wall, then stir quickly for 60 minutes, and mix well; add 15kg of deionized water , stir at a slow speed for 15 minutes, after scraping the bottom and walls, stir quickly for 60 minutes, and mix well; add 1.4kg of styrene-butadiene rubber SBR, st...

Embodiment 3

[0056] A method for preparing an ultrafine diamond-coated isolation film, comprising the steps of:

[0057] (1) Weigh each raw material in the solid component in the slurry, and the mass percentage of each component is in brackets

[0058] Ultrafine diamond powder and inorganic filler 10kg (80%),

[0059] (9kg of ultrafine diamond powder, 1kg of inorganic filler alumina powder, the quality of ultrafine diamond powder is 90% of the total mass of ultrafine diamond powder and inorganic filler.)

[0060] Filler CMC 1.8kg (14.4%),

[0061]Glue SBR 0.7kg (5.6%);

[0062] Measure 1kg of alumina powder, 9kg of ultra-fine diamond powder and 1.8kg of CMC, first stir slowly for 15 minutes, scrape the bottom and scrape the wall, then stir quickly for 60 minutes, mix well; add 15kg of deionized water, stir slowly for 15 minutes, scrape the bottom After scraping the wall, stir quickly for 60 minutes and mix well; add 0.7kg styrene-butadiene rubber SBR, stir slowly for 15 minutes, after s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com