Activated carbon material and preparation method thereof and supercapacitor

A technology of activated carbon and carbonized materials, which is applied in the fields of activated carbon materials, preparation, and supercapacitors, can solve the problems such as the inability to meet the requirements of supercapacitors for the specific surface area performance of electrode materials, the inability to ensure the charge-discharge cycle performance of supercapacitors, and the harsh chemical activation conditions. , to achieve excellent high current performance, improve specific capacitance and charge-discharge cycle performance, and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

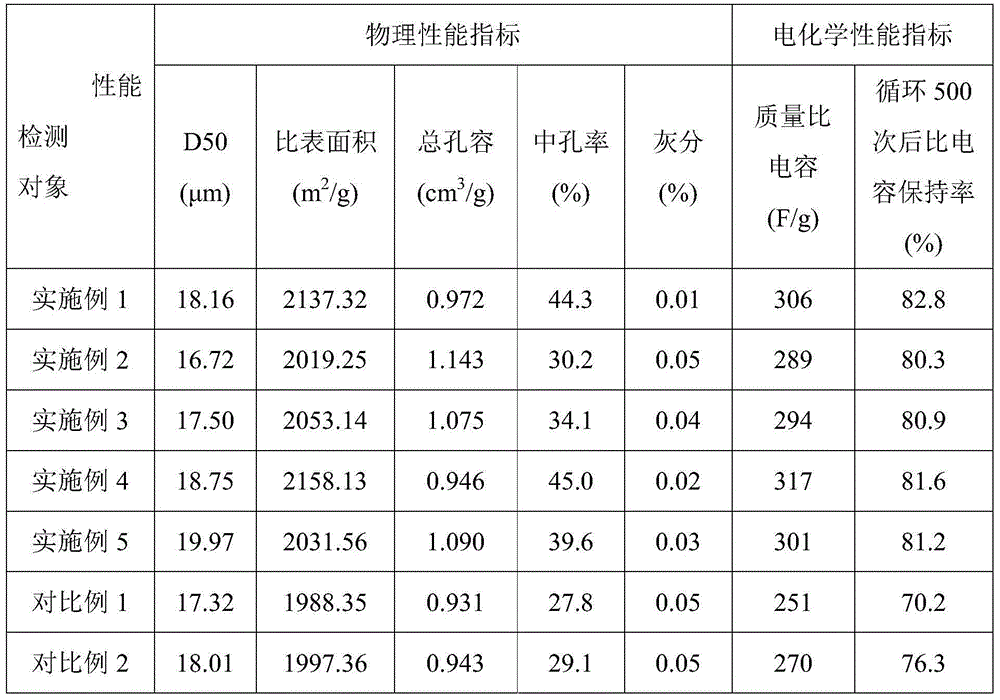

Embodiment 1

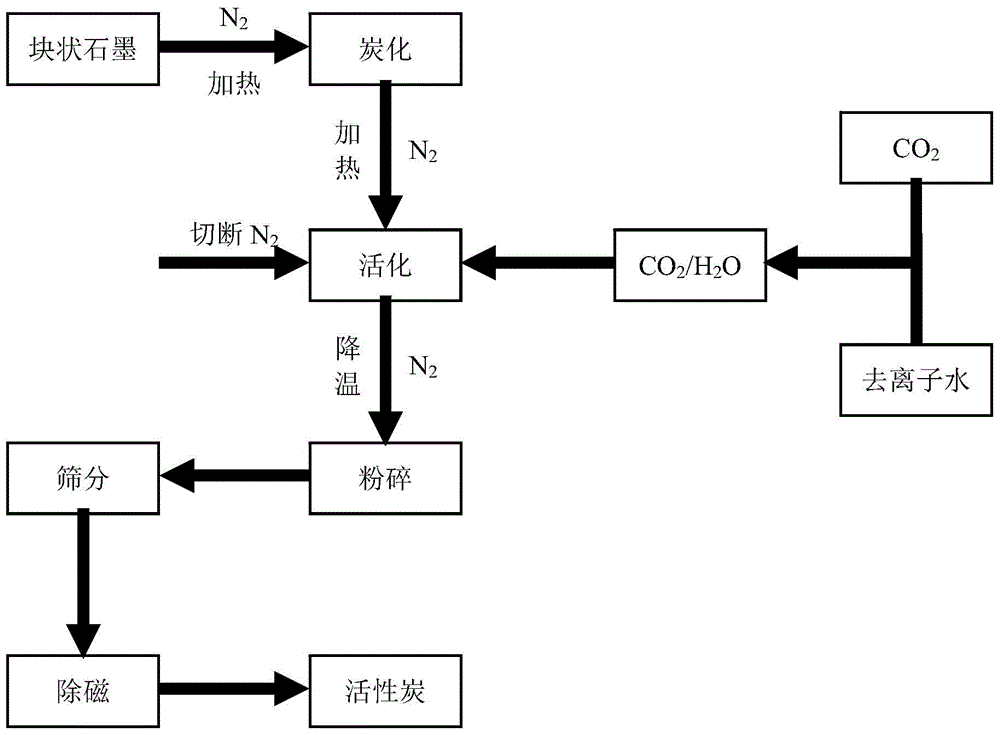

[0037] The active carbon material of this embodiment is prepared by the following preparation method with block graphite as raw material, such as figure 1 As shown, the specific operation steps are:

[0038] 1) Block graphite carbonization: select D 50 22.5μm, the specific surface area is 80m 2 / g of bulk graphite particles, in N 2 Under protection, heat up to 600°C at a heating rate of 15°C / min in a closed kiln, carbonize for 2 hours, and then cool down to room temperature to obtain carbonized material;

[0039] 2) Carbonized material activation: take 20g of the carbonized material obtained in step 1) and place it in an activation furnace, 2 Under protection, the temperature was raised to 800°C at a heating rate of 15°C / min, and the N 2 , while passing CO 2 The gas flowing out after passing through deionized water, the flow rate of the gas flowing out is controlled at 200mL / min, stop heating after 4 hours of activation, and cut off the CO 2 , at N 2 Protect and drop to...

Embodiment 2

[0042] The active carbon material of this embodiment is prepared by the following preparation method with block graphite as raw material, and the specific operation steps are:

[0043] 1) Block graphite carbonization: select D 50 20μm, the specific surface area is 90m 2 / g of bulk graphite particles, in N 2 Under protection, heat up to 500°C at a heating rate of 10°C / min in a closed kiln, carbonize for 3 hours, and then cool down to room temperature to obtain carbonized material;

[0044] 2) Activation of the carbonized material: get 30g of the carbonized material obtained in step 1) and place it in an activation furnace. 2 Under protection, the temperature was raised to 700°C at a rate of 10°C / min, and the feeding of N was stopped. 2 , while passing CO 2 The outflow of gas after deionized water, the flow rate of the outflow gas is controlled at 300mL / min, stop heating after activation for 6 hours, and cut off CO 2 , at N 2 Protect and drop to room temperature, pulverize...

Embodiment 3

[0047] The active carbon material of this embodiment is prepared by the following preparation method with block graphite as raw material, and the specific operation steps are:

[0048] 1) Carbonization of bulk graphite: select D 50 25μm, the specific surface area is 85m 2 / g of bulk graphite particles, in N 2 Under protection, heat up to 550°C at a heating rate of 10°C / min in a closed kiln, carbonize for 2.5 hours, and then cool down to room temperature to obtain carbonized material;

[0049] 2) Activation of the carbonized material: take 25g of the carbonized material obtained in step 1) and place it in an activation furnace. 2 Under protection, the temperature was raised to 750°C at a heating rate of 10°C / min, and the N 2 , while passing CO 2 The outflow of gas after deionized water, the flow rate of the outflow gas is controlled at 250mL / min, stop heating after activation for 5 hours, and cut off the CO 2 , at N 2 Protect and drop to room temperature, pulverize with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Mass specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com