Preparation method of lithium ion battery gel polymer electrolyte

A gel polymer and lithium-ion battery technology, which is applied in the field of lithium-ion batteries, can solve the problems of low ion conductivity, poor mechanical properties, and unsatisfactory ion conductivity, so as to improve liquid absorption capacity and liquid retention capacity, Effect of improving ionic conductivity and mechanical properties, good ionic conductivity and electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

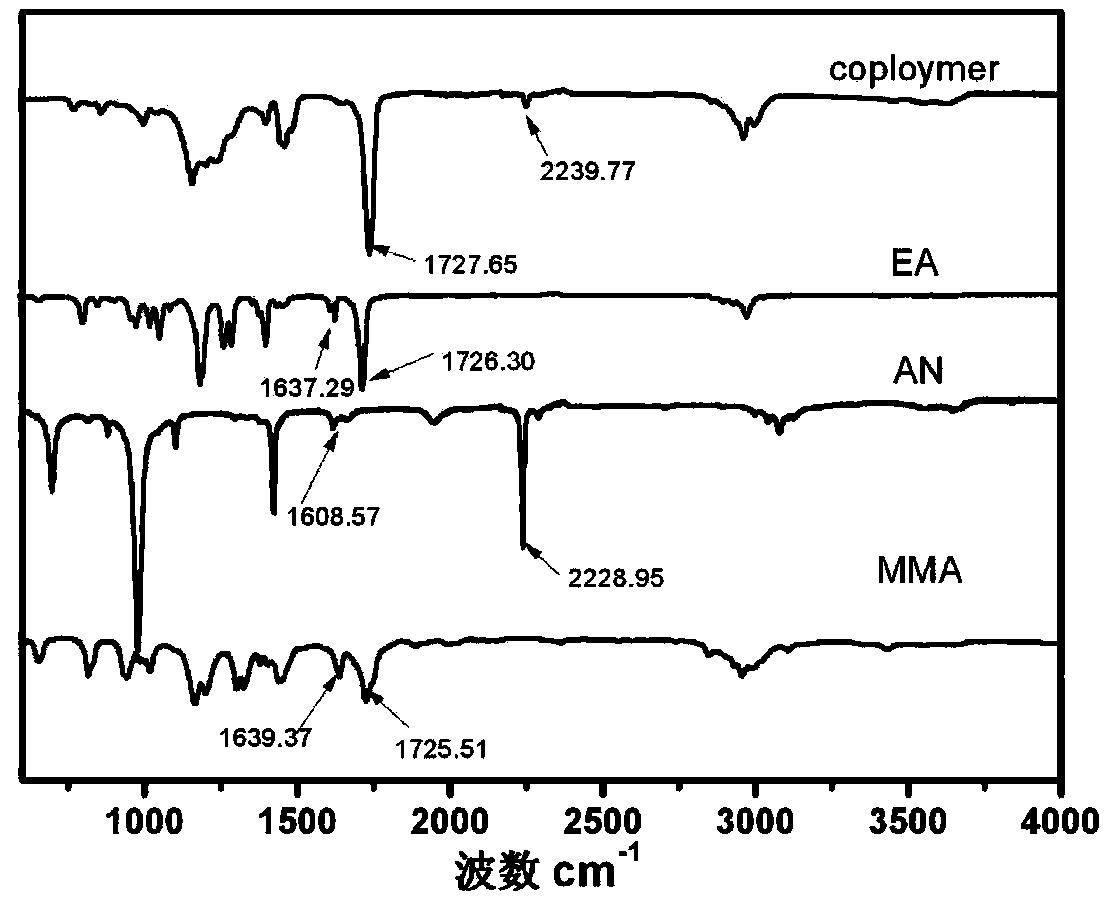

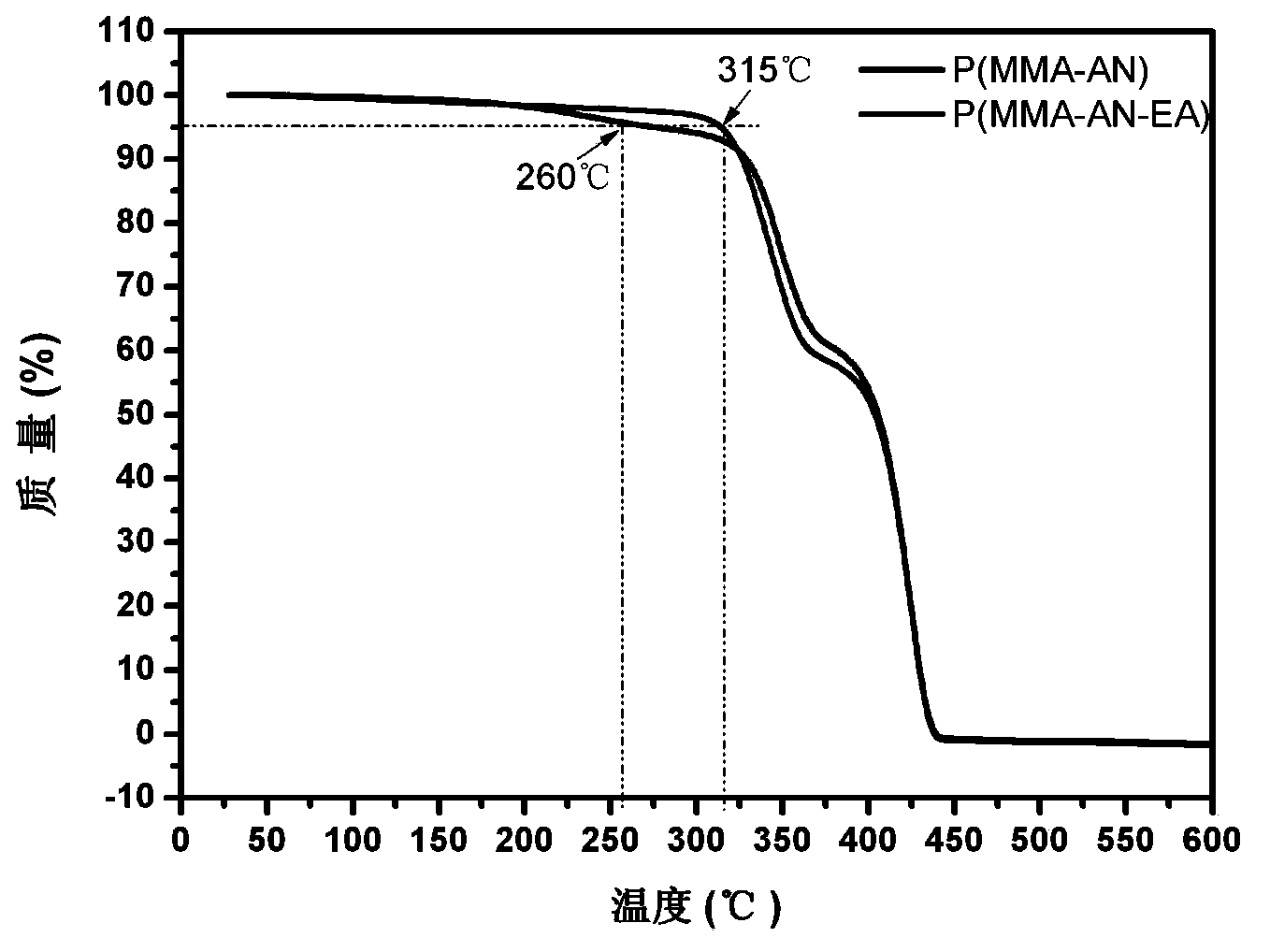

[0034] A preparation method of a lithium ion battery gel polymer electrolyte, comprising the following steps: using methyl methacrylate, acrylonitrile and ethyl acrylate as functional monomers, and preparing polymer poly(methyl methacrylate) by emulsion polymerization -acrylonitrile-ethyl acrylate); dissolve the polymer in N-N dimethylformamide, add a pore-forming agent whose mass is 0-5% of N-N dimethylformamide, coat it on the support, and use phase transfer The method prepares a porous gel polymer film; immersing the gel polymer film in the lithium ion battery electrolyte to obtain the lithium ion battery gel polymer electrolyte.

[0035] Preferably, the mass ratio of methyl methacrylate, acrylonitrile and ethyl acrylate is (1-5):(1-5):1.

[0036] Preferably, the pore-forming agent is at least one of polyethylene glycol, polyvinylpyrrolidone, and urea. More preferably, the pore forming agent is polyethylene glycol 400 (PEG400).

[0037] Preferably, the support body is pol...

Embodiment 1

[0055] (1) in N 2 Under the atmosphere, add 1 mass part of potassium lauryl sulfate to 66.9 mass parts of deionized water to dissolve, add 32 mass parts of monomers MMA, AN and EA, MMA: AN: EA (mass ratio) = 1: 5:1, stir evenly, raise the temperature to 55°C, dissolve 0.1 parts by mass of potassium persulfate in 40 mL of deionized water, and add in several times within 0.5 hours of reaction at a speed of 1-2 s / drop with a syringe; 1000rpm continued to stir and react for 8 hours to obtain a white emulsion;

[0056] (2) Prepare an aluminum sulfate aqueous solution with a concentration of 2wt%, pour the emulsion into 1 times the volume of aluminum sulfate aqueous solution, stir to break the emulsion, wash with 55°C deionized water for 3 times, then wash with absolute ethanol for 3 times, and finally use Wash with deionized water 3 times to obtain a white polymer; then dry the white polymer under vacuum at 55°C for 24 hours to obtain poly(methyl methacrylate-acrylonitrile-ethyl a...

Embodiment 2

[0060] (1) in N 2 Under the atmosphere, add 1.5 parts by mass of sodium lauryl sulfate to 68.35 parts by mass of deionized water to dissolve, add 30 parts by mass of MMA, AN and EA, MMA: AN: EA (mass ratio) = 4:2: 1. Stir evenly, raise the temperature to 60°C, dissolve 0.15 parts by mass of sodium persulfate in 60 mL of deionized water, and add in several times within 0.5 hours of reaction at a rate of 1-2 s / drop with a syringe; 800 rpm continuously Stirred and reacted for 6 hours to obtain a white emulsion;

[0061] (2) Prepare an aluminum sulfate aqueous solution with a concentration of 3wt%, pour the emulsion into 1 times the volume of aluminum sulfate aqueous solution, stir to break the emulsion, wash with 60°C deionized water for 4 times, then wash with absolute ethanol for 4 times, and finally use Wash with deionized water 4 times to obtain a white polymer; then dry the white polymer at 60°C in vacuum for 24 hours to obtain poly(methyl methacrylate-acrylonitrile-ethyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com