Fracture coal-rock mass quasi-three dimensional prestressed reinforcement method

A prestressed, coal-rock mass technology, applied in the direction of earthwork drilling, shaft lining, tunnel lining, etc., can solve the problems of complex construction, high support cost, large overall deformation, etc., and achieve simple construction and low support cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The specific implementation steps of a quasi-three-dimensional prestressed reinforcement method for fractured coal and rock mass are as follows:

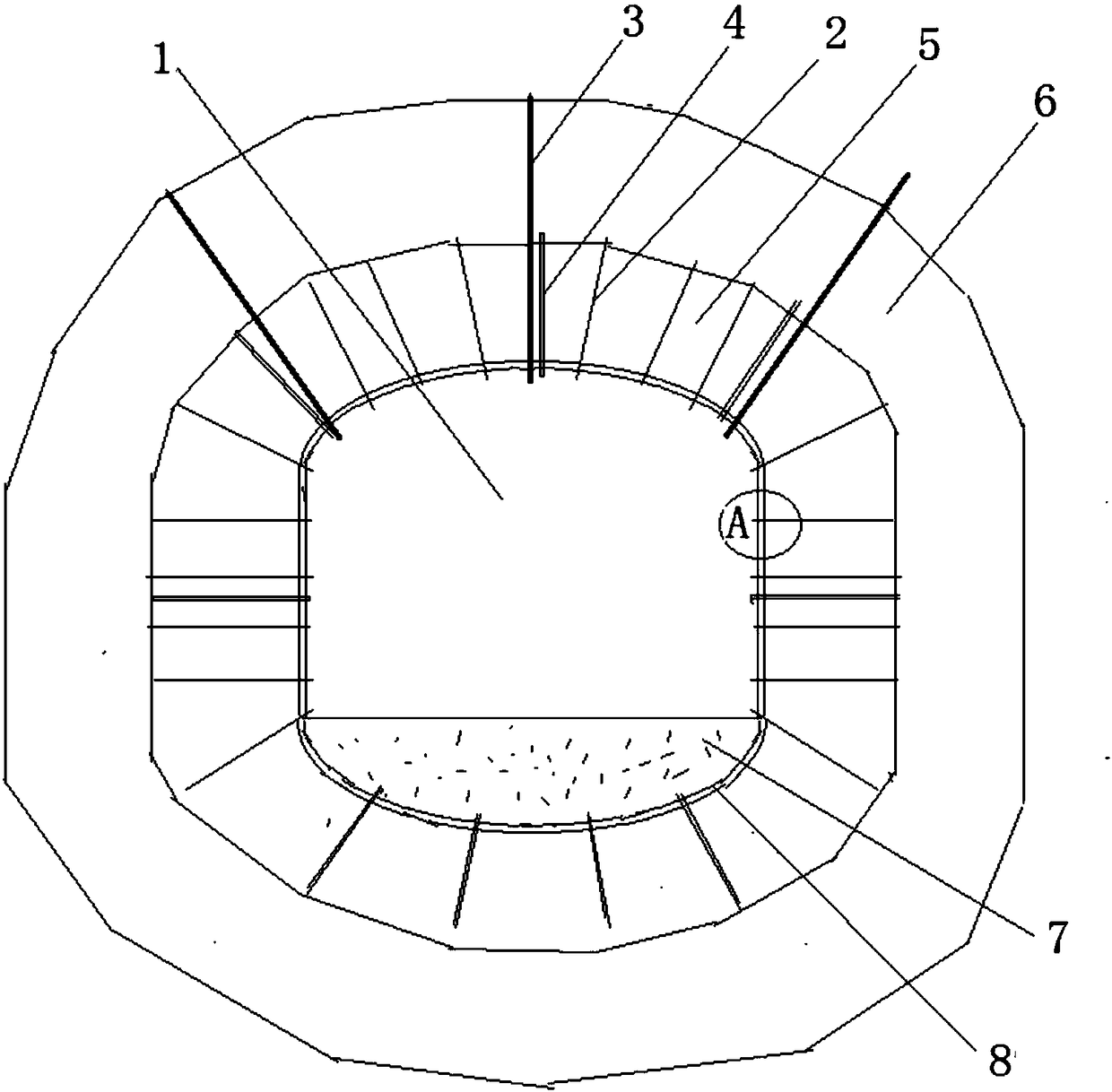

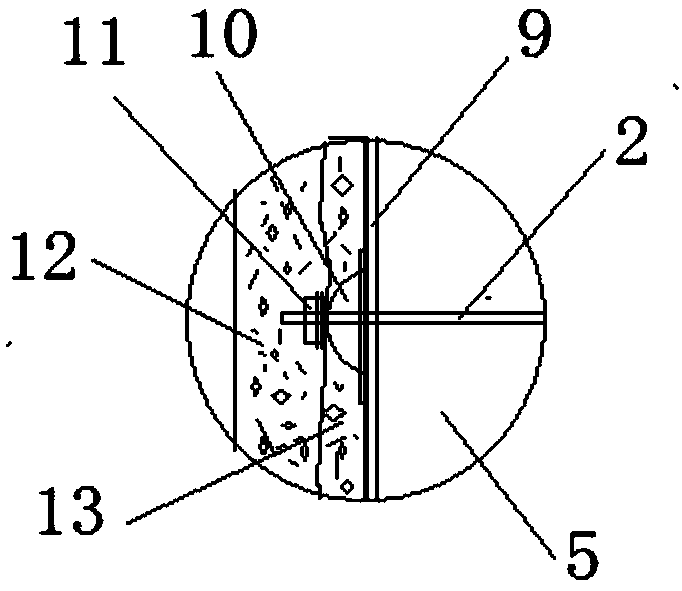

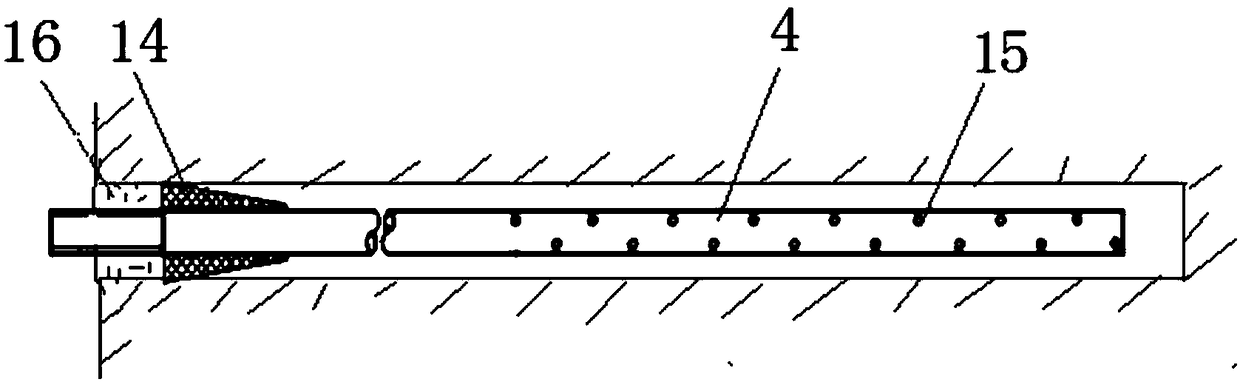

[0032] A quasi-three-dimensional prestressed reinforcement method for fractured coal and rock masses, such as figure 1 , figure 2 Shown:

[0033] The first step, the initial support of anchor net cable

[0034] First, tunnel 1 according to the design shape of the tunnel section, and spray the concrete with a shotcrete machine while digging, which is called the initial spray layer 13, and the thickness of the spray layer is not less than 50mm to seal the weak and broken roadway surrounding rock surface; The two sides and roof of roadway 1 are installed with pressure-relief anchors 2 in a row spacing of 900mm×700mm, and pressure-relief anchor cables 3 are installed on the center line of the roof and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Preload force | aaaaa | aaaaa |

| Preload force | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com