Metal organic framework material-molecular sieve composite material and preparation method thereof

A metal-organic framework and composite material technology, applied in the field of metal-organic framework material-molecular sieve composite material and its preparation, can solve problems such as poor hydrothermal stability, achieve excellent adsorption performance, improve specific surface area, and have wide application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

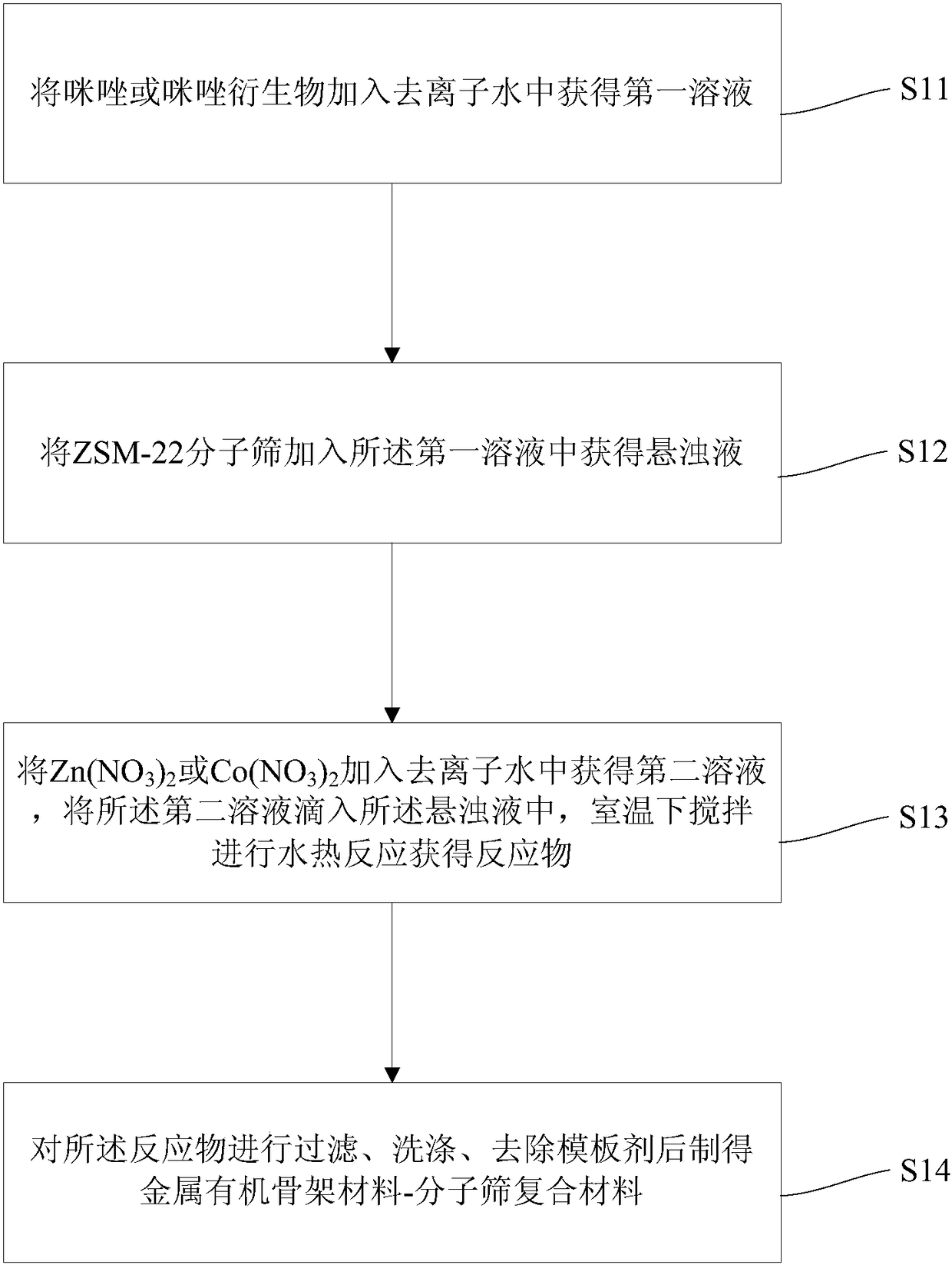

[0043] Such as figure 1 As shown, the present invention provides a kind of preparation method of metal-organic framework material-molecular sieve composite material, and described preparation method comprises: will contain Zn(NO 3 ) 2 or Co(NO 3 ) 2 , and imidazole or imidazole derivatives solution, adding ZSM-22 molecular sieve, stirring at room temperature for hydrothermal reaction to obtain the reactant, filtering, washing, and removing the template agent to prepare the metal organic framework material-molecular sieve composite Material.

[0044] As an example, the metal-organic framework material-molecular sieve composite material has a TON molecular sieve structure and a corresponding structure of a ZIF-8 molecular sieve.

[0045] As an example, the imidazole or imidazole derivatives, ZSM-22 molecular sieve, and Zn(NO 3 ) 2 or Co(NO 3 ) 2 The range of mass ratio is 55.4:1~50:0.5~5. Further, the imidazole or imidazole derivatives, ZSM-22 molecular sieve, and Zn(NO...

Embodiment 1

[0061] Dissolve 55.4g of 2-methylimidazole in 160mL of deionized water (30°C) to obtain the first solution, add 5g of ZSM-22 molecular sieve to the first solution to obtain a suspension, and dissolve 2.3g of zinc nitrate in 16mL of deionized Zinc nitrate solution was obtained in water, and the zinc nitrate solution was slowly added dropwise to the suspension, stirred for 2 hours to obtain a metal-organic framework material-molecular sieve suspension, washed twice with deionized water and then twice with ethanol, at 100°C Drying at the bottom to obtain metal-organic framework material-molecular sieve (ZIF-8 / ZSM-22) composite material.

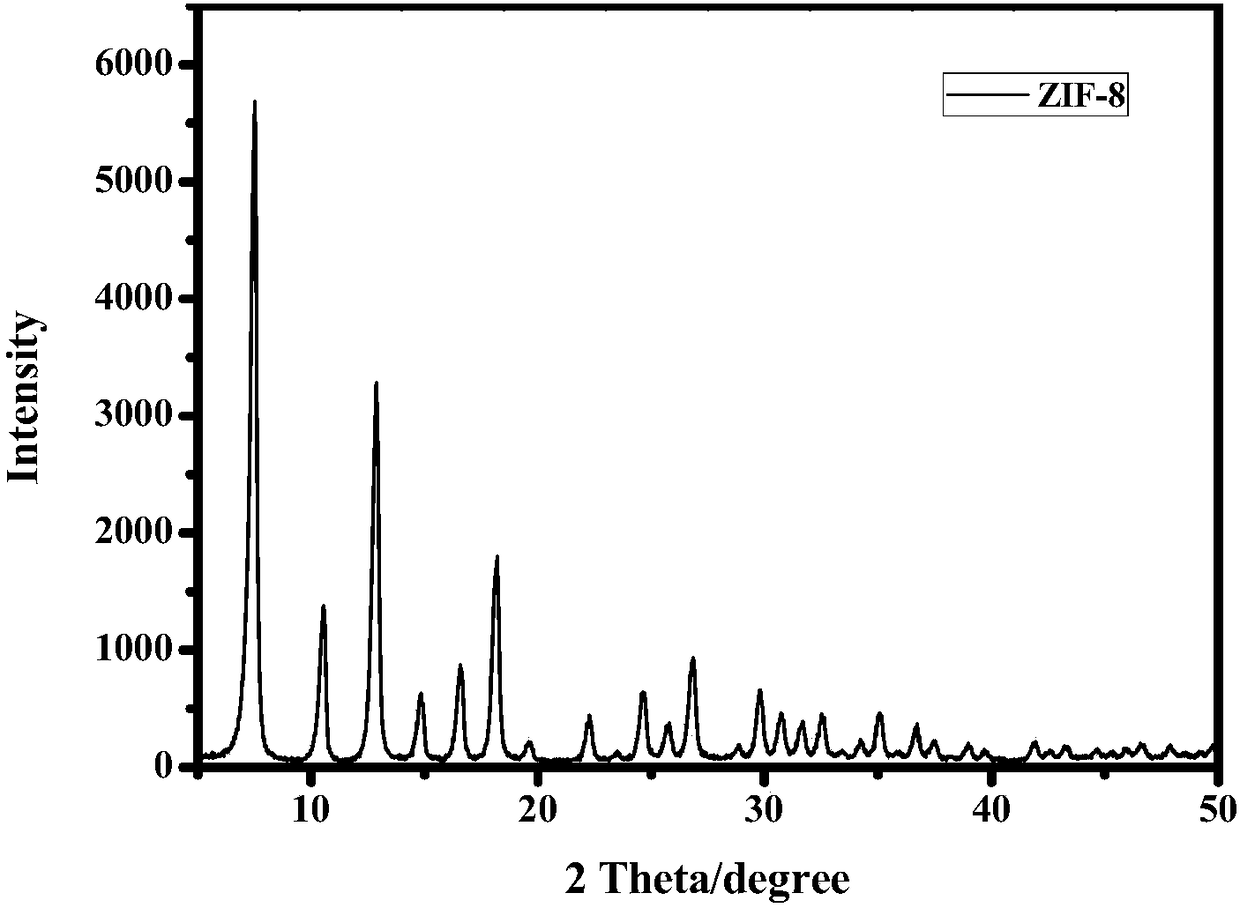

[0062] attached figure 2 It is the XRD characterization of the metal organic framework material-molecular sieve (ZIF-8 / ZSM-22) composite material of Example 1.

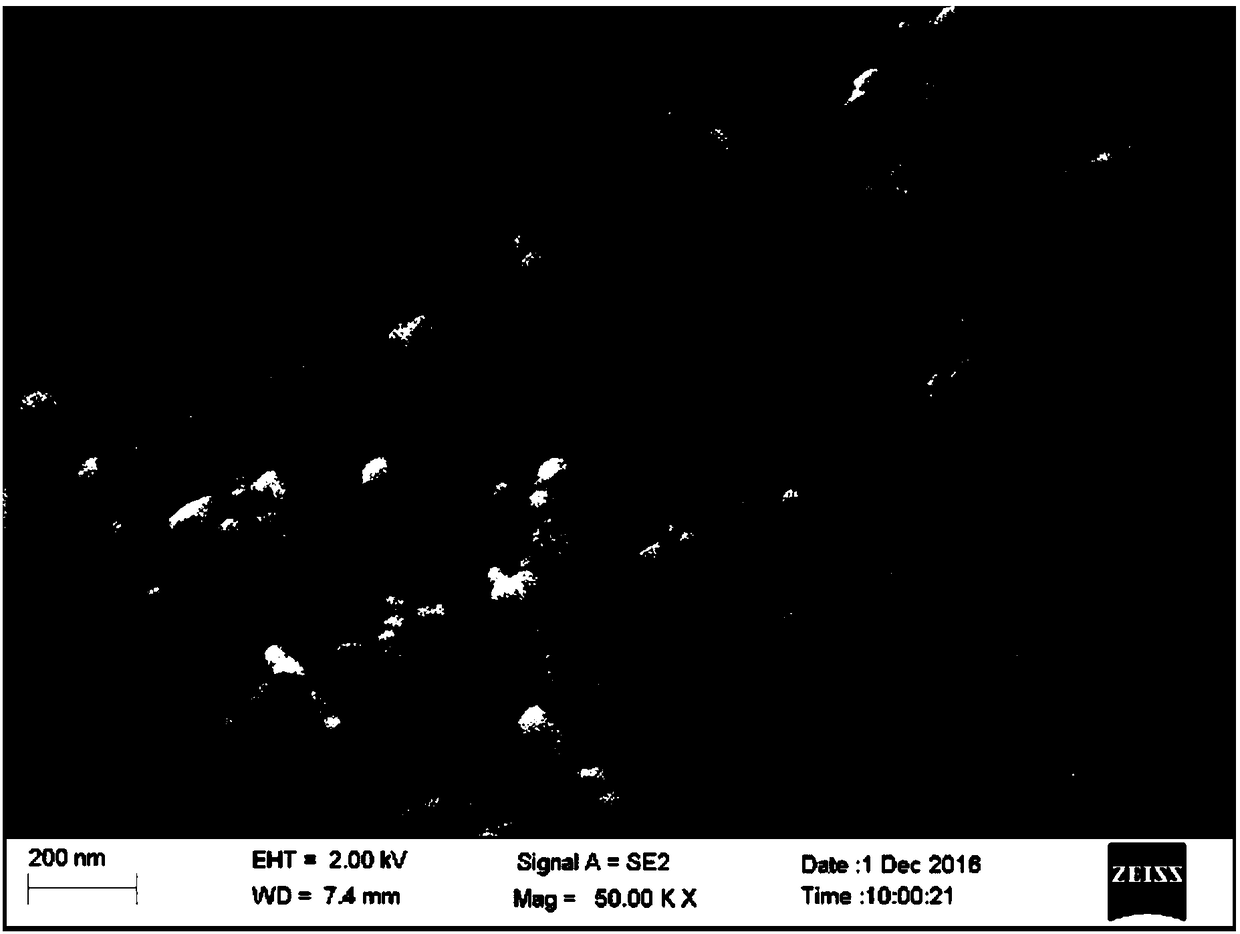

[0063] attached image 3 It is the SEM scanning electron micrograph of Example 1 metal-organic framework material-molecular sieve (ZIF-8 / ZSM-22) composite material.

Embodiment 2

[0065] Dissolve 55.4g of 2-methylimidazole in 150mL of deionized water (30°C) to obtain the first solution, add 10g of ZSM-22 molecular sieve to the first solution to obtain a suspension, and dissolve 0.5g of zinc nitrate in 15mL of deionized Zinc nitrate solution was obtained in water, and the zinc nitrate solution was slowly added dropwise to the suspension, stirred for 4 hours to obtain a metal organic framework material-molecular sieve suspension, and then washed twice with deionized water and then twice with ethanol, at 100 ° C Drying at the bottom to obtain metal-organic framework material-molecular sieve (ZIF-8 / ZSM-22) composite material.

[0066] attached Figure 4 It is the XRD characterization of the metal organic framework material-molecular sieve (ZIF-8 / ZSM-22) composite material of Example 2.

[0067] attached Figure 5 It is the SEM scanning electron micrograph of example 2 metal organic framework material-molecular sieve (ZIF-8 / ZSM-22) composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com