Preparation method of graphene material of supercapacitor

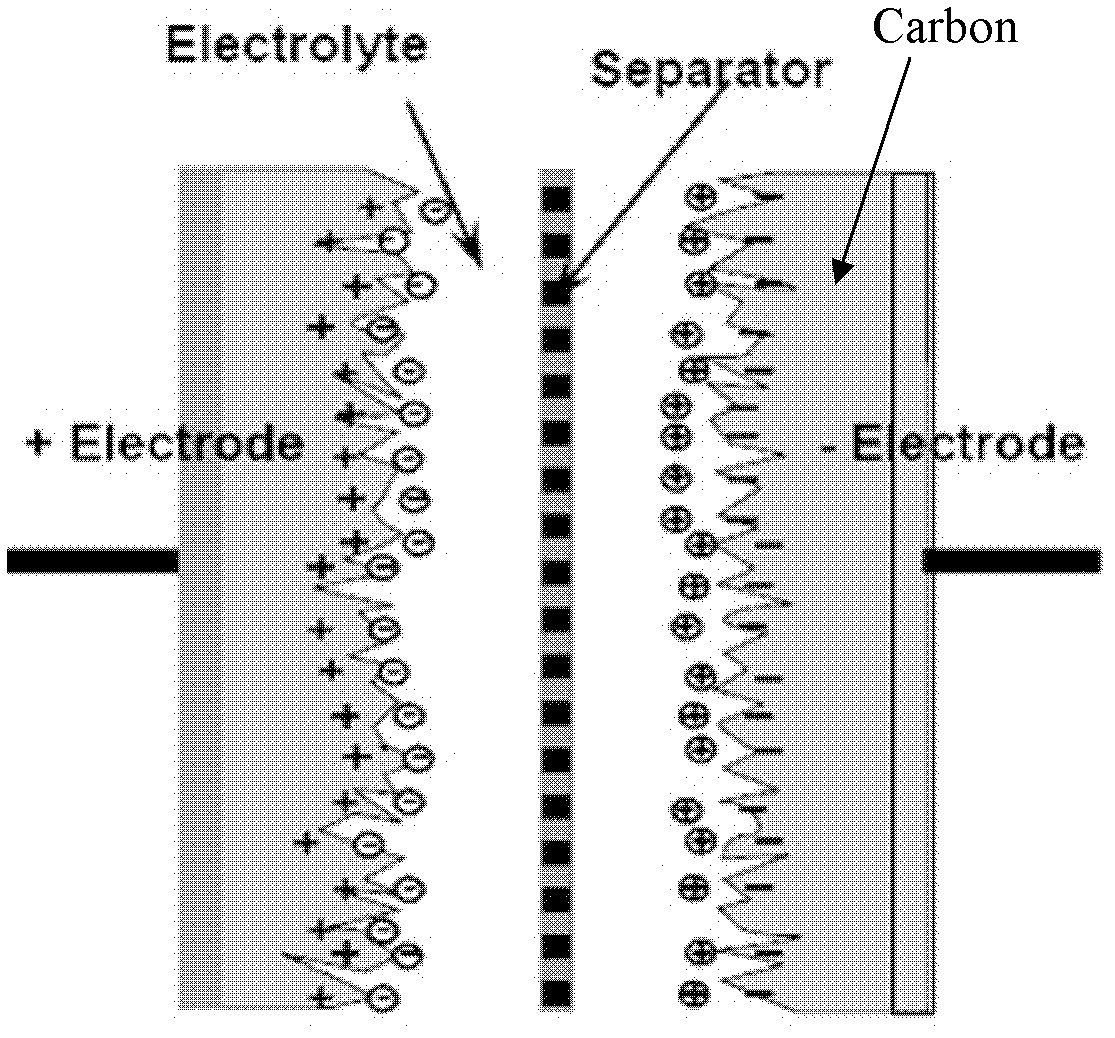

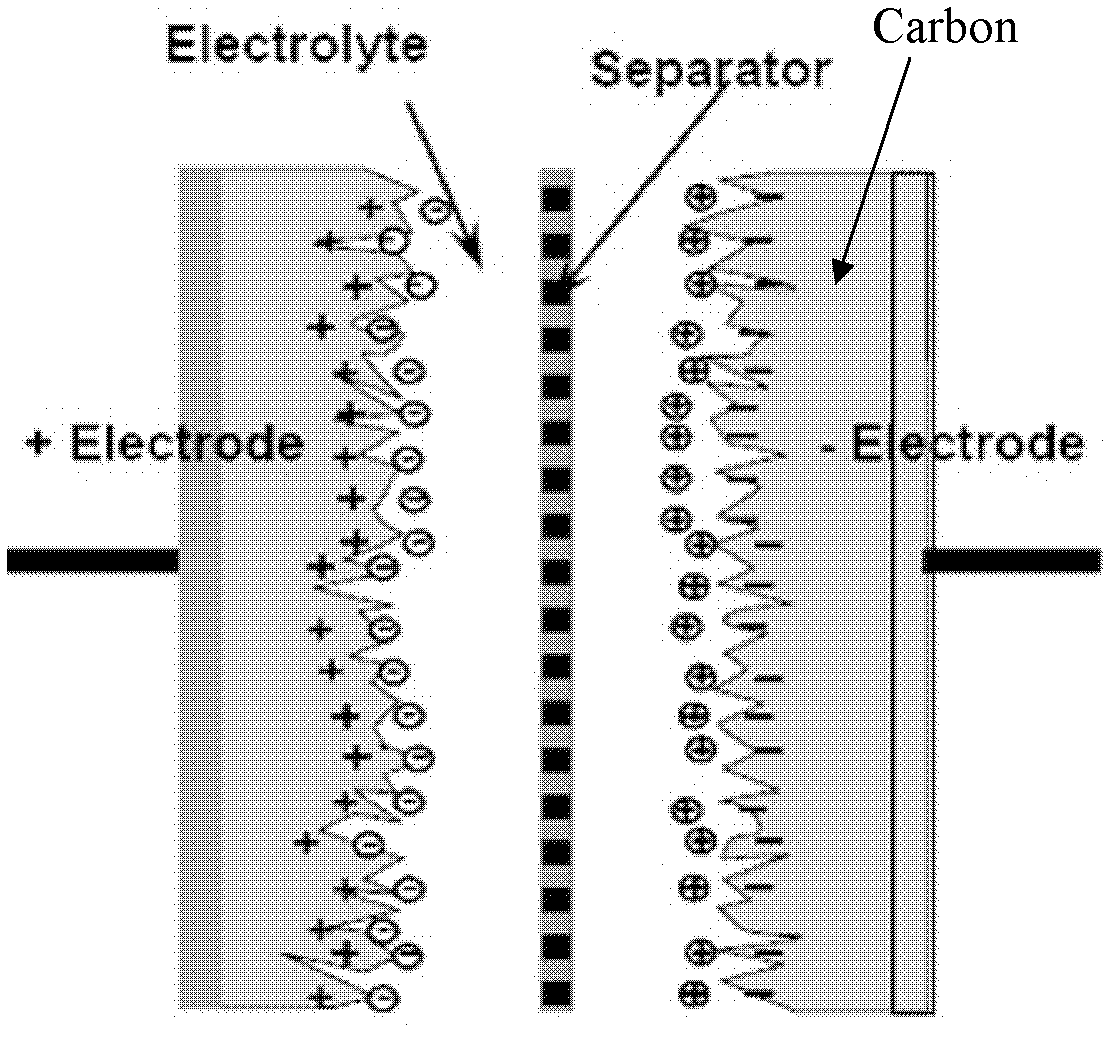

A supercapacitor, graphene technology, applied in the manufacture of capacitors, hybrid/electric double-layer capacitors, electrolytic capacitors, etc., can solve the problems of high equipment requirements, unsuitable for industrial production, unstable cycle performance, complex processes, etc. The effect of charge storage, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment one: Graphite oxide is placed in vial, it is sealed with bottle stopper. React for 30-120s in a microwave oven with medium-high heat, repeat the above operation, and prepare 0.4g of expanded graphene. 0.3gZnCl 2 Configure it as a 6mol / L solution, add 0.4g graphene and stir vigorously for 6-24h. Filter the solution with a filter membrane, and wash it with acid and deionized water several times until neutral. Vacuum dry in a drying oven at 50°C for 10-20 hours. Pass CO in CVD at 600-900°C 2 Gas, reaction 2h. Pass N during heating and cooling 2 for protection. The prepared supercapacitor electrode material has a specific capacity of 160 F / g and a specific energy of 32 Wh / Kg measured at a current density of 100 mA / g.

Embodiment 2

[0014] Embodiment 2: Graphite oxide is placed in a beaker, and it is sealed with a bottle stopper. React for 30-120s in a microwave oven with medium-high heat, repeat the above operation, and prepare 0.4g of expanded graphene. 0.6gZnCl 2 Configure it as a 6mol / L solution, add 0.4g graphene and stir vigorously for 6-24h. Filter the solution with a filter membrane, and wash it with acid and deionized water several times until neutral. Vacuum dry in a drying oven at 50°C for 10-20 hours. Pass CO in CVD at 600-900°C 2 Gas, reaction 2h. Pass N during heating and cooling 2 for protection. The prepared supercapacitor electrode material has a specific capacity of 186 F / g and a specific energy of 37 Wh / Kg measured at a current density of 100 mA / g.

Embodiment 3

[0015] Embodiment 3: Graphite oxide is placed in a beaker, and it is sealed with a bottle stopper. React for 30-120s in a microwave oven with medium-high heat, repeat the above operation, and prepare 0.4g of expanded graphene. 1gZnCl 2 Configure it as a 6mol / L solution, add 0.4g graphene and stir vigorously for 6-24h. Filter the solution with a filter membrane, and wash it with acid and deionized water several times until neutral. Vacuum dry in a drying oven at 50°C for 10-20 hours. Pass CO in CVD at 600-900°C 2 Gas, reaction 2h. Pass N during heating and cooling 2 for protection. The prepared supercapacitor electrode material has a specific capacity of 200 F / g and a specific energy of 40 Wh / Kg measured at a current density of 100 mA / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com