A magnesium alloy base material with high salt spray resistance and strong weather resistance protective coating, preparation method and application method

A technology of protective coatings and magnesium alloys, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of limited practical application and prone to corrosion, and achieve excellent salt spray resistance and good corner coverage , the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

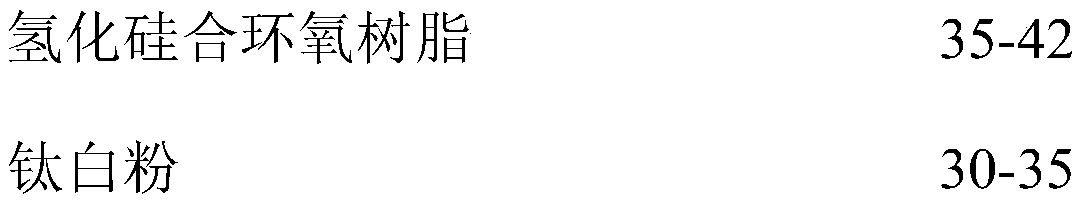

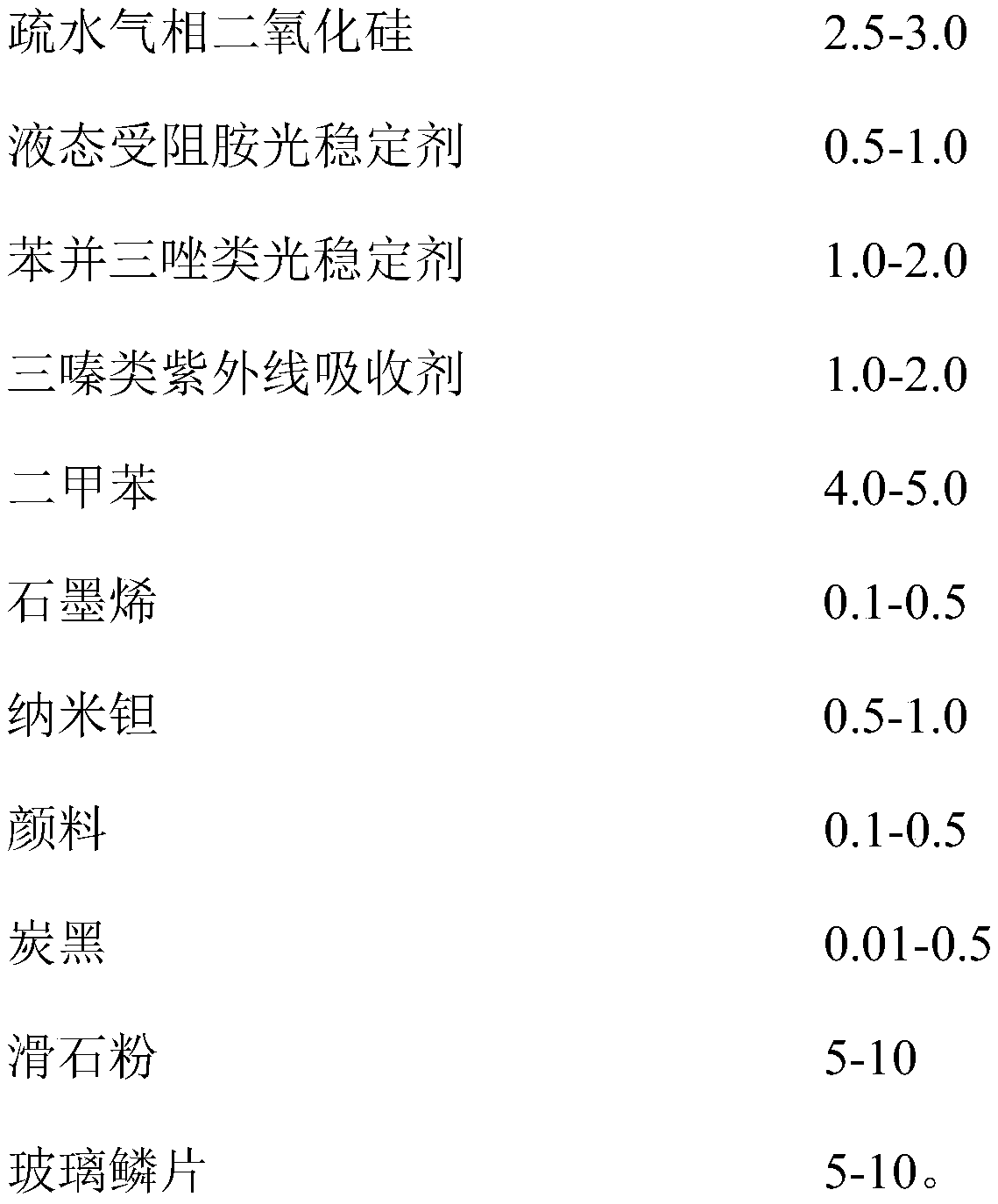

[0033] A magnesium alloy base material with high salt spray resistance and strong weather resistance protective coating, the coating includes the following raw materials in parts by weight, as shown in Example 1 in Table 1:

[0034] Table 1 Coating Formulation

[0035] (1) Stir the hydrogenated silicon-containing epoxy resin of the formula amount under the condition of 300-700 rev / min, and stir

[0036]

[0037] Add titanium dioxide, fumed silica, light stabilizer and UV absorber, xylene, graphene, nano-tantalum, yellow pigment, carbon black in turn under the same conditions, and stir for 10 minutes at 700-1200 rpm , and then, grind to a fineness of less than 15 microns;

[0038] (2) Stir the ground raw materials in step (1) at 300-700 rpm, add talcum powder and glass flakes under stirring conditions, stir at 800-1200 rpm for 15-20 minutes, and the fineness is less than 35 microns to make the coating.

Embodiment 2

[0040] A magnesium alloy base material with high salt spray resistance and strong weather resistance protective coating, the coating includes the following raw materials in parts by weight, as shown in Example 2 in Table 1:

[0041] The preparation method of the coating is the same as that of the coating in Example 1.

Embodiment 3

[0043] A magnesium alloy base material with high salt spray resistance and strong weather resistance protective coating, the coating includes the following raw materials in parts by weight, as shown in Example 3 in Table 1:

[0044] The preparation method of the coating is the same as that of the coating in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com