A spraying tool for elongated automotive interior parts

A technology for automotive interior parts and tools, which is applied to spray devices, spray discharge devices and other directions to achieve the effects of saving paint, reducing production costs and high paint rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

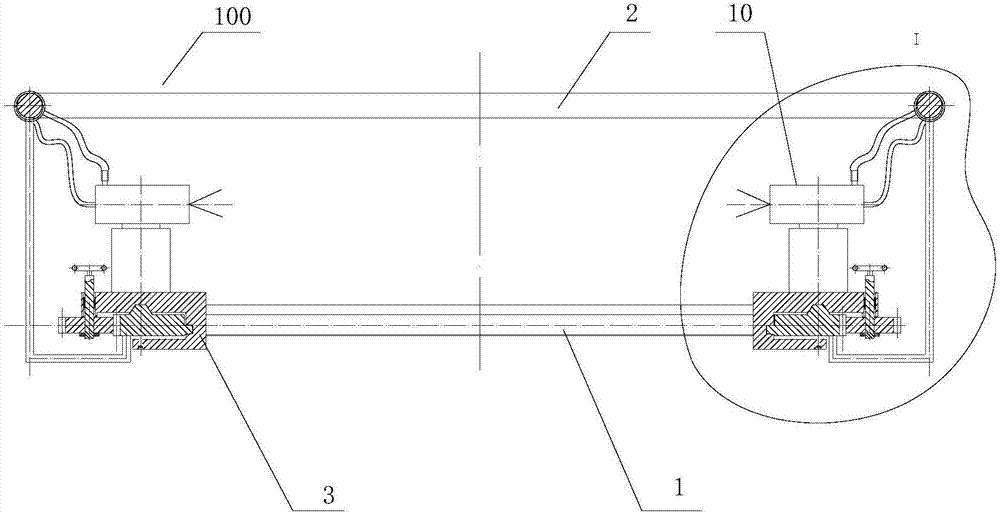

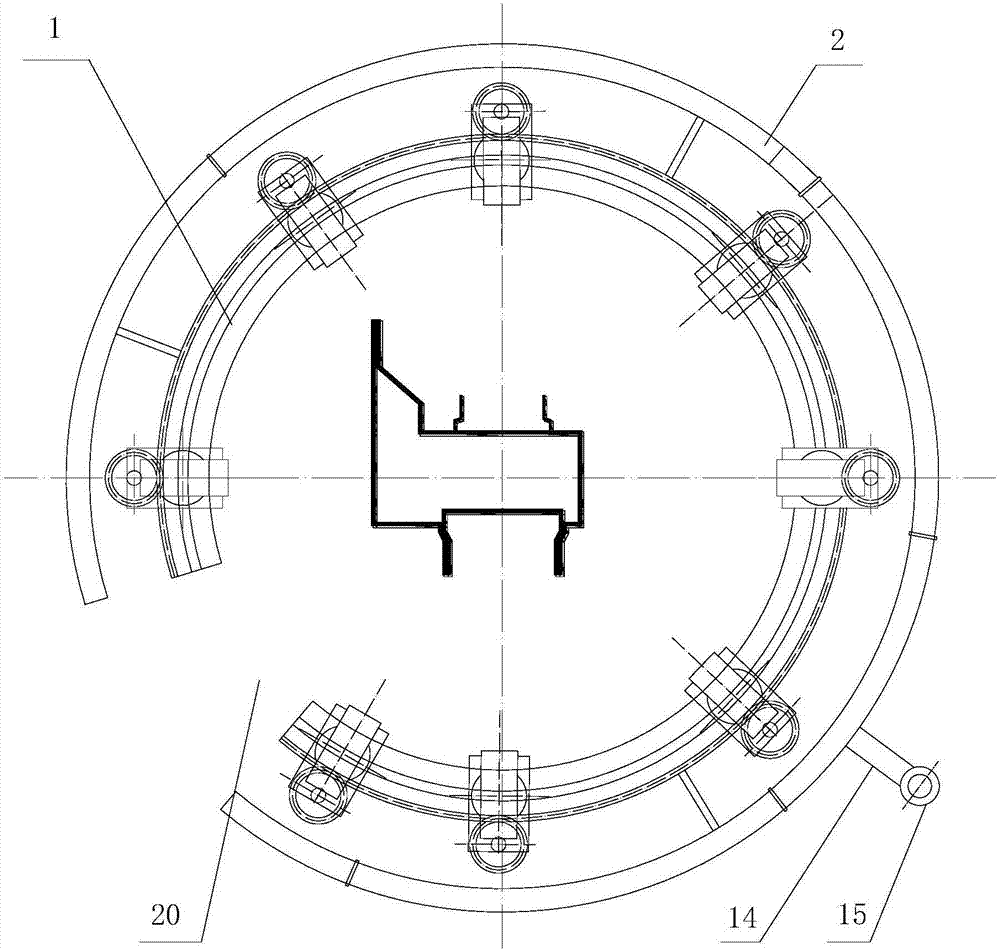

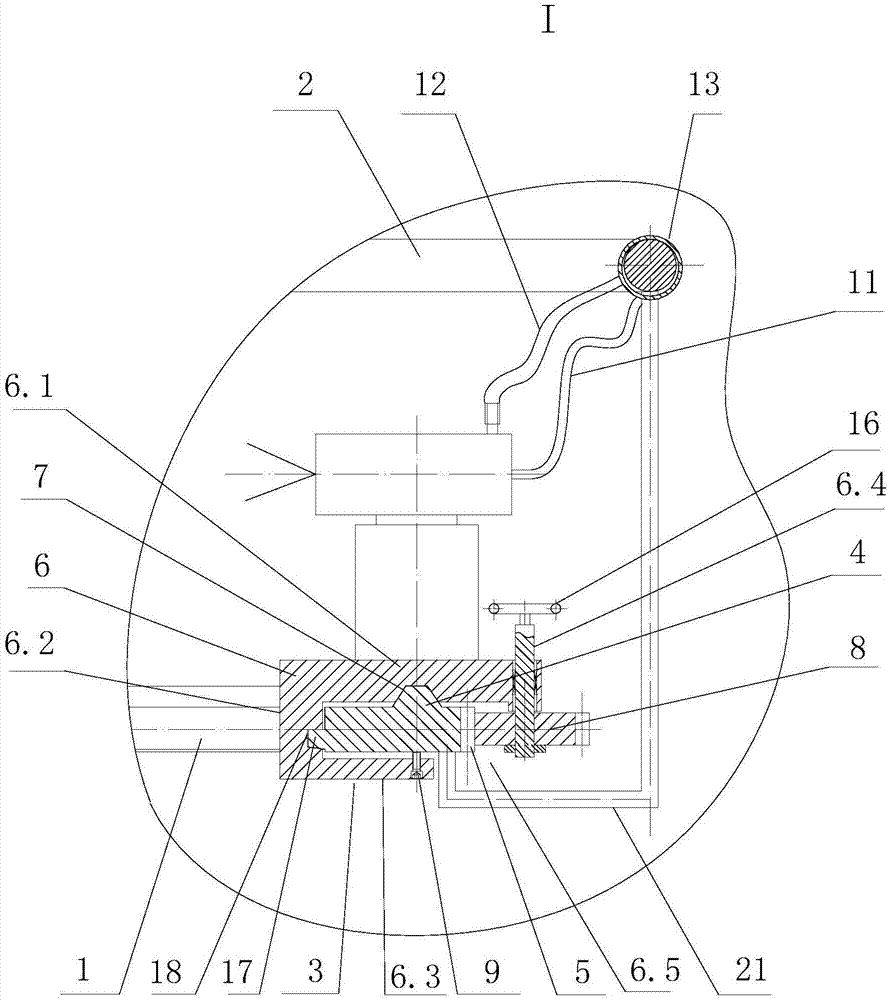

[0043]As shown in the figure, a spraying tool for elongated automotive interior parts includes an angular spacing adjustment mechanism 100 and a spraying sector adjustment mechanism 200. The angular spacing adjustment mechanism 100 includes a first annular body 1 and a second annular body arranged in parallel. The main body 2, the first annular main body 1 is provided with a gap 20 for the workpiece to enter, the first annular main body 1 is slidably provided with a plurality of nozzle seats 3, and the spray gun 10 is slidably arranged radially along the first annular main body On the nozzle seat 3; the first annular body 1 includes a first guide rail 4, a second guide rail 17 and external teeth 5, the first guide rail 4 is arranged on the upper surface of the annular main body 1, and the outer surface of the first annular main body 1 The edge is provided with external teeth 5, and the second guide rail 17 is arranged on the inner surface of the ring-shaped main body 1. The noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com