LED display module and display screen

A display module and module technology, applied in the field of display screens, can solve problems such as inability to maintain the power supply and control part of the front display screen, and achieve the effects of good structural regularity, accuracy assurance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

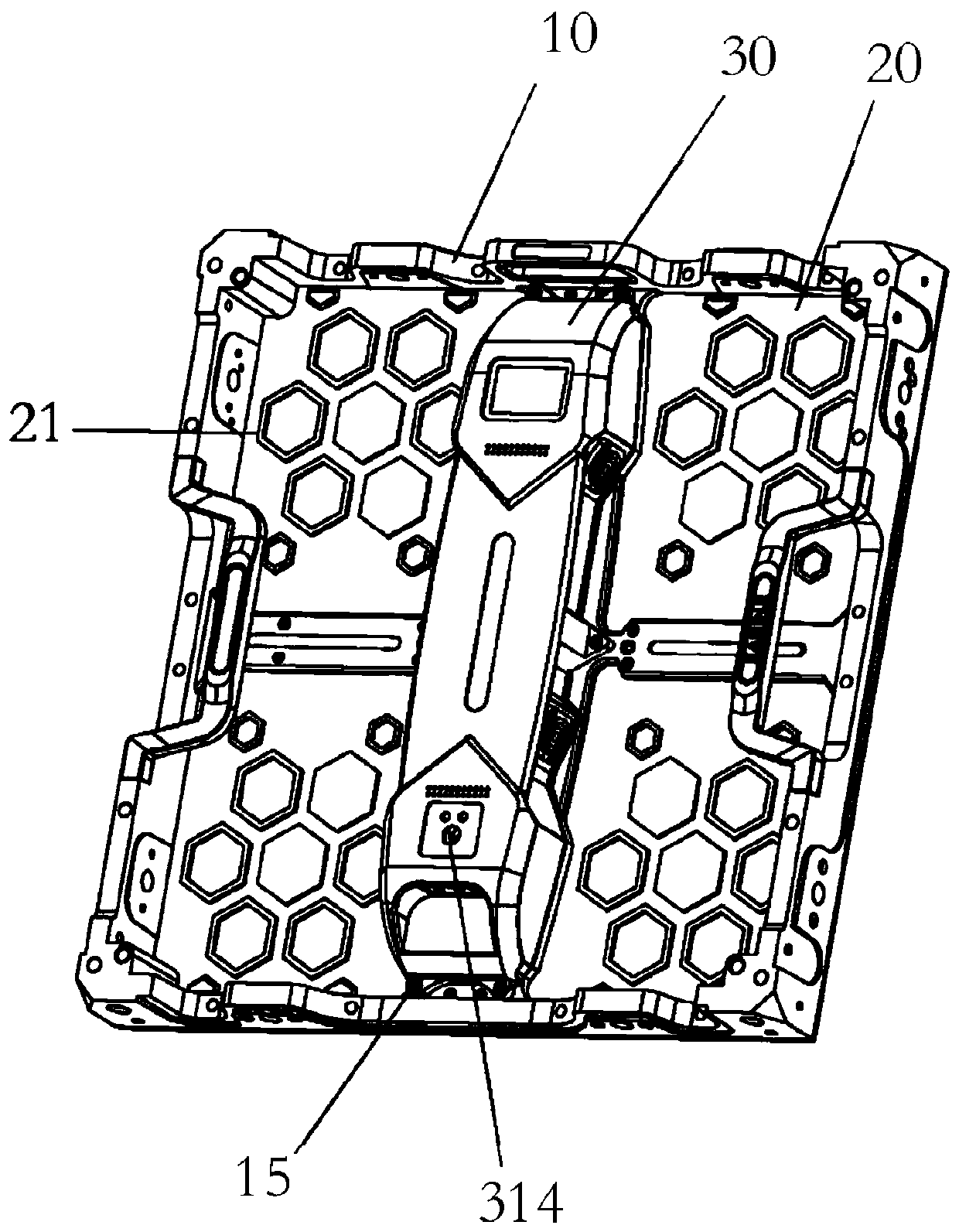

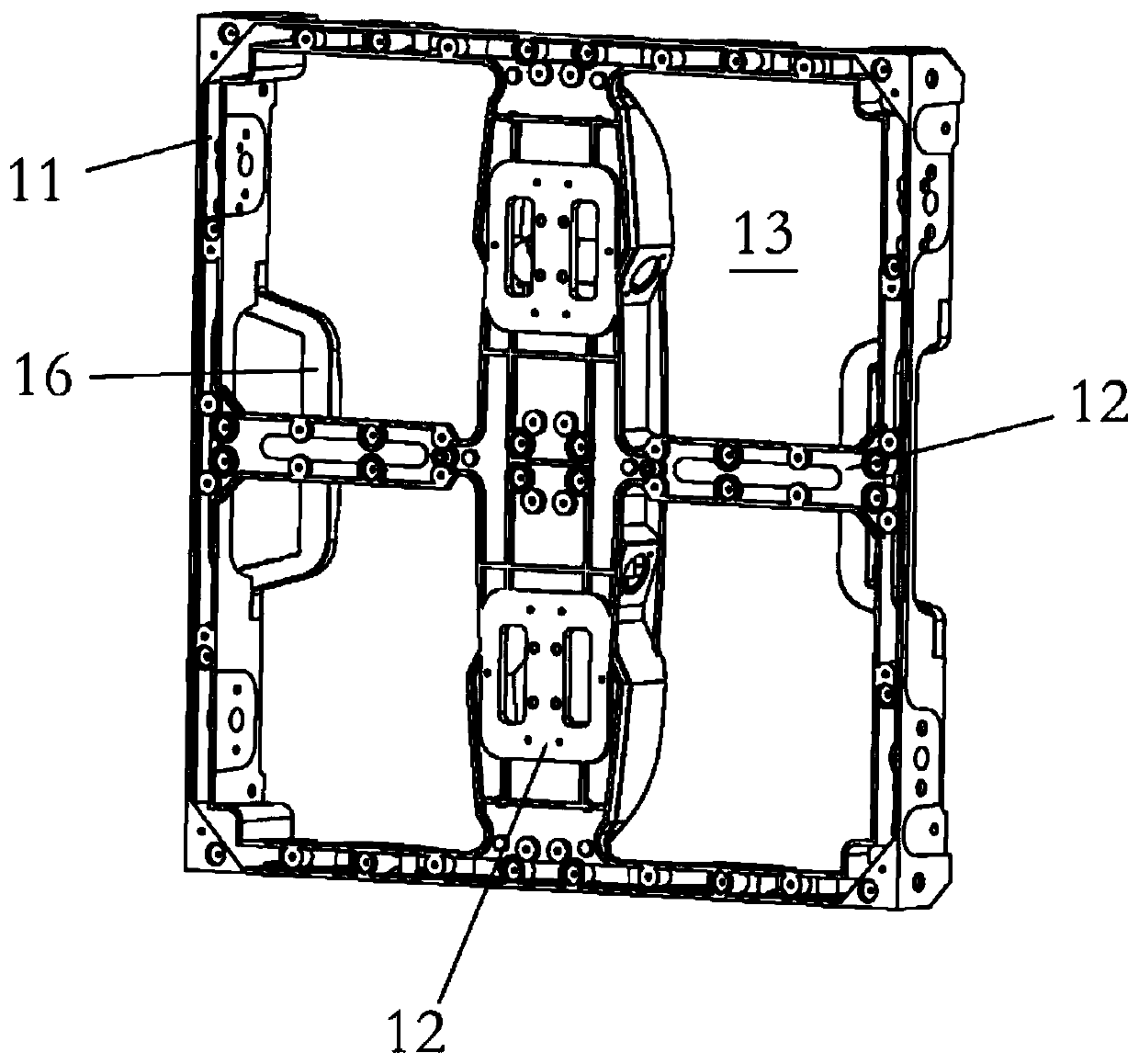

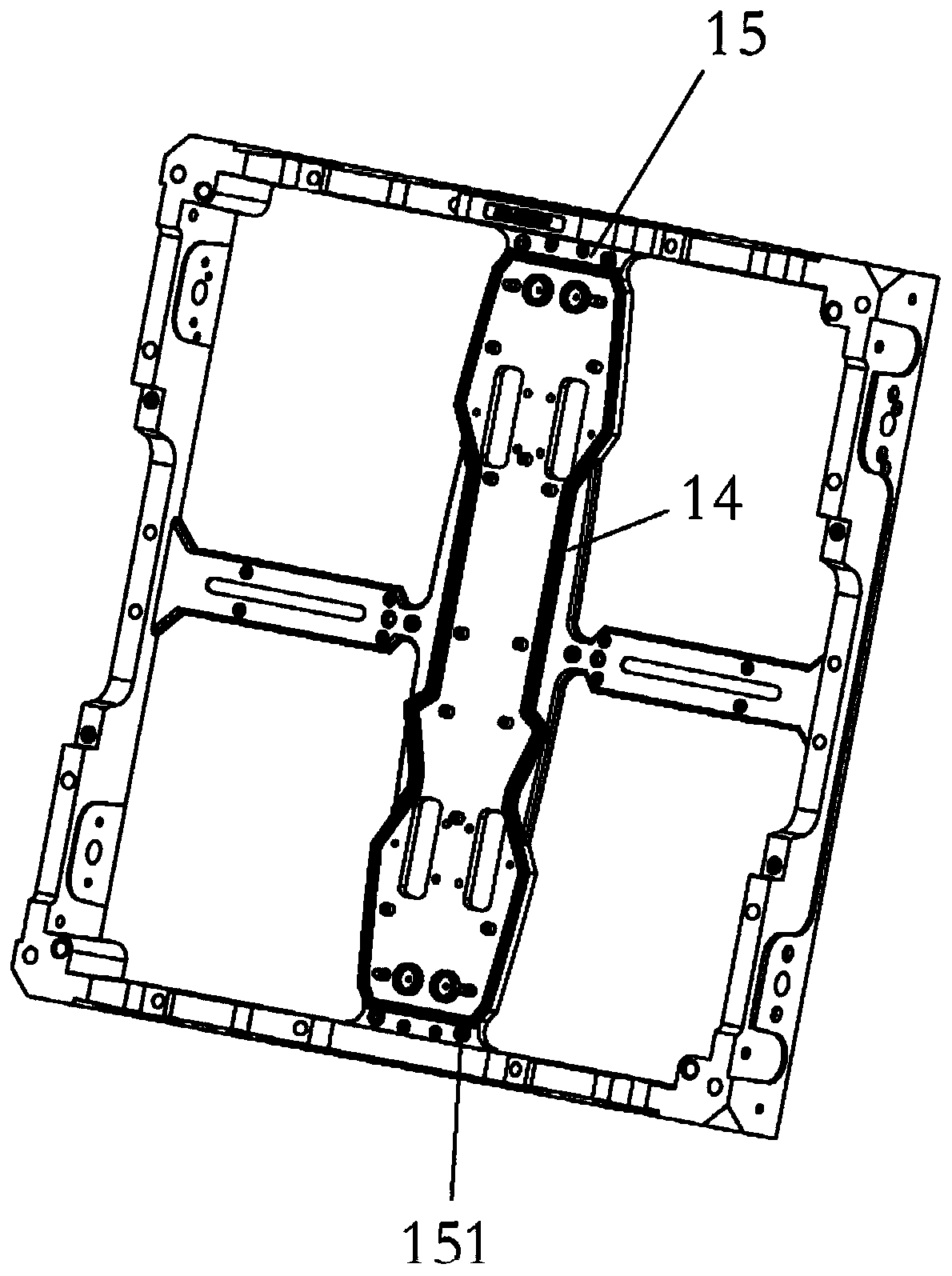

[0035] A LED display module, such as figure 1 -5, including the main frame 10, the module assembly 20 and the rear cover part 30, wherein the module assembly 20 is set on the front side of the main frame 10; the back cover part 30 is set on the back side of the main frame 10.

[0036] The main frame 10 in this example has a square structure, which includes an outer frame 11 and a cross-shaped support frame bar 12, which can provide four module installation positions 13, and the module assembly 20 includes a shape that is adapted to the module installation positions 13 The module body 21, the module body 21 is arranged on the module installation position 13 and is connected with the magnetic attraction between the main frame 10, wherein, the specific magnetic attraction connection can adopt the existing magnetic structure, which is not mentioned here Introducing its structure in detail again, the outer frame 11 adopts the structure of splicing with each other, and it only needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com