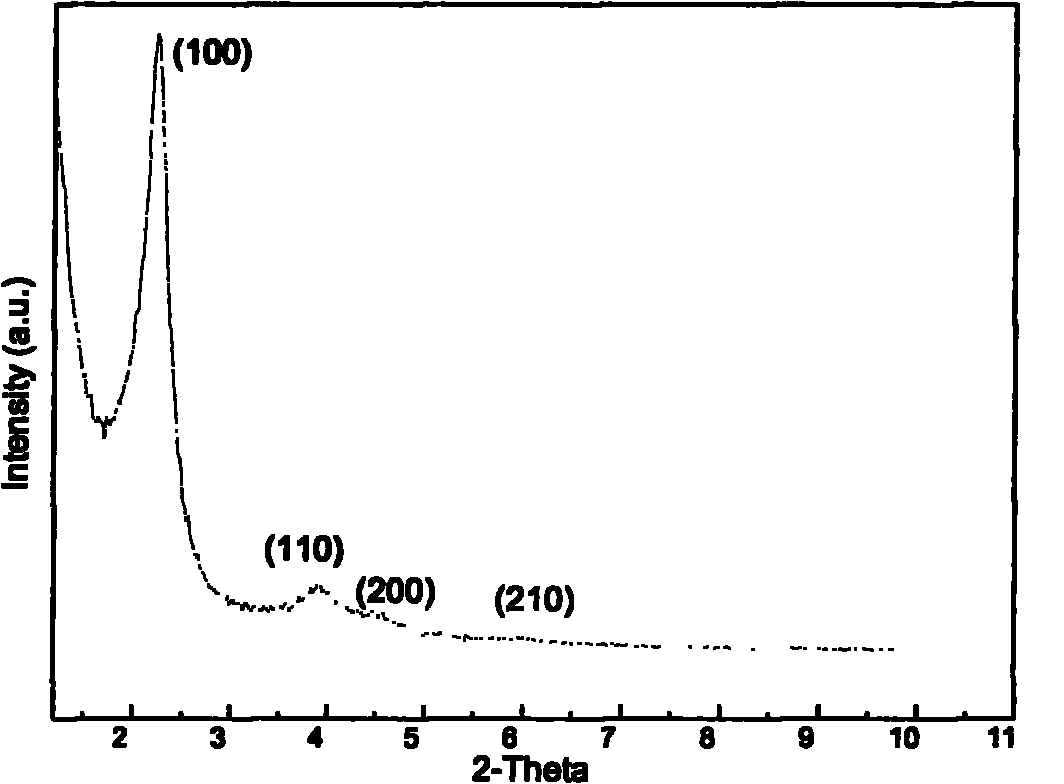

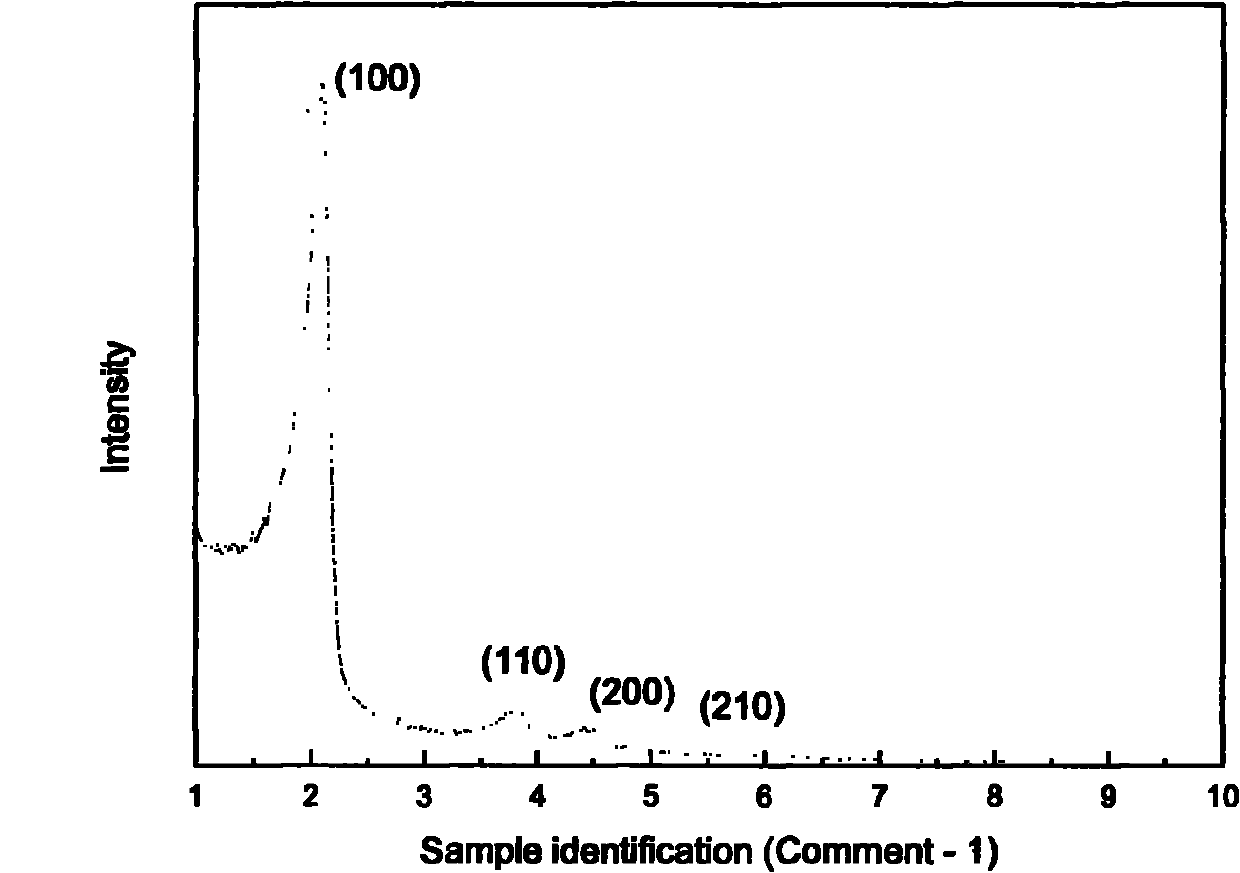

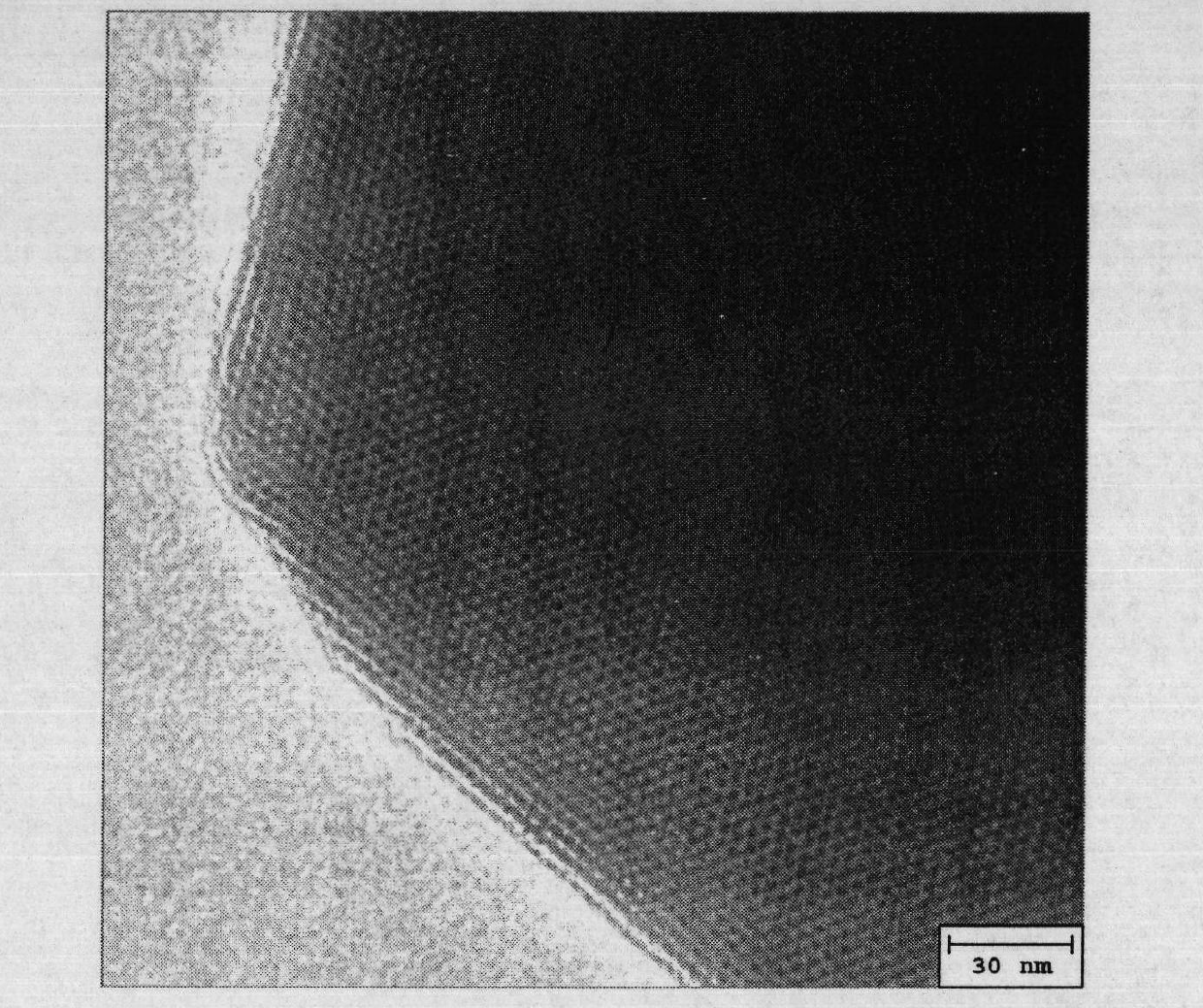

Preparation method of high regularity mesoporous molecular sieve Fe-MCM-41

A mesoporous molecular sieve, fe-mcm-41 technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve uneven distribution of metal ions, reduced material regularity, uneven surface, etc. problem, to achieve strong application value, enhanced selectivity and activity, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 4.86g CTAB to 100ml deionized water, stir for 15min, then add 13.9ml tetraethyl orthosilicate dropwise to obtain a clear solution, continue stirring for 6 hours, then add lye to adjust the pH of the system to 11. The mixed slurry was continuously stirred for 8 hours, then suction-filtered, washed until the pH of the filtrate was 7, and dried at 100-120° C. to obtain the matrix Si-MCM-41. Then it was put into a solution containing 2.4g of potassium ferricyanide, stirred vigorously for 6 hours, and the product was suction filtered, washed, and dried at 373K for 6 hours. at 1°C·min -1 The rate was programmed to increase the temperature to 550°C, keep the temperature for 5h, and remove the template to obtain the target product. Denote it as sample 1.

Embodiment 2

[0026] Add 4.86g CTAB to 100ml deionized water, stir for 15min, then add 13.9ml tetraethyl orthosilicate dropwise to obtain a clear solution, continue stirring for 6 hours, then add lye to adjust the pH of the system to 11. The mixed slurry was continuously stirred for 8 hours, then suction-filtered, washed until the pH of the filtrate was 7, and dried at 100-120° C. to obtain the matrix Si-MCM-41. Then it was put into a solution containing 2.8g of potassium ferricyanide, stirred vigorously for 6 hours, and the product was suction filtered, washed, and dried at 373K for 6 hours. at 1°C·min -1 The rate was programmed to increase the temperature to 550°C, keep the temperature for 5h, and remove the template to obtain the target product. Denoted as sample 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com