ATS type silicon-aluminum molecular sieve as well as preparation method and application thereof

A silicon-aluminum molecular sieve and molecular sieve technology, applied in molecular sieves and alkali exchange compounds, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high silicon-aluminum ratio and achieve high acid strength and high acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention relates to an ATS type silicon aluminum molecular sieve, its preparation method and application.

[0044] According to the present invention, the ATS-type silica-alumina molecular sieve can exist in an uncalcined state (synthesized state) or in a calcined state. When present in a synthesized state, the ATS-type silica-alumina molecular sieve generally has a schematic chemical composition represented by the formula "oxide·organic structure directing agent·water". In the case of existing in a calcined state, it is known that molecular sieves sometimes contain a certain amount of moisture (especially immediately after synthesis), but the present invention does not consider it necessary to specify the amount of moisture because the moisture The presence or absence of will not substantially affect the XRD spectrum of the molecular sieve.

[0045] According to the present invention, in the schematic chemical composition represented by the formula "oxide·organic...

Embodiment 1

[0077] With 5.801 grams of deionized water, 7.161 grams of organic structure directing agent 4-pyrrolidinylpyridine, 14.515 grams of silica sol (containing SiO 2 40% by weight), 3.9474 grams of aluminum isopropoxide, and 4.834 grams of hydrofluoric acid (containing 40% by weight of HF) were mixed uniformly, and after stirring at room temperature for 2 hours, the raw material solution was stirred at 80° C., and 9.05 grams of water were evaporated to obtain Mixture, final material ratio (mol ratio) is:

[0078] al 2 o 3 / SiO 2 =0.10

[0079] 4-Pyrrolidinylpyridine / SiO 2 =0.5

[0080] F / SiO 2 =1.0

[0081] h 2 O / SiO 2 =4.8

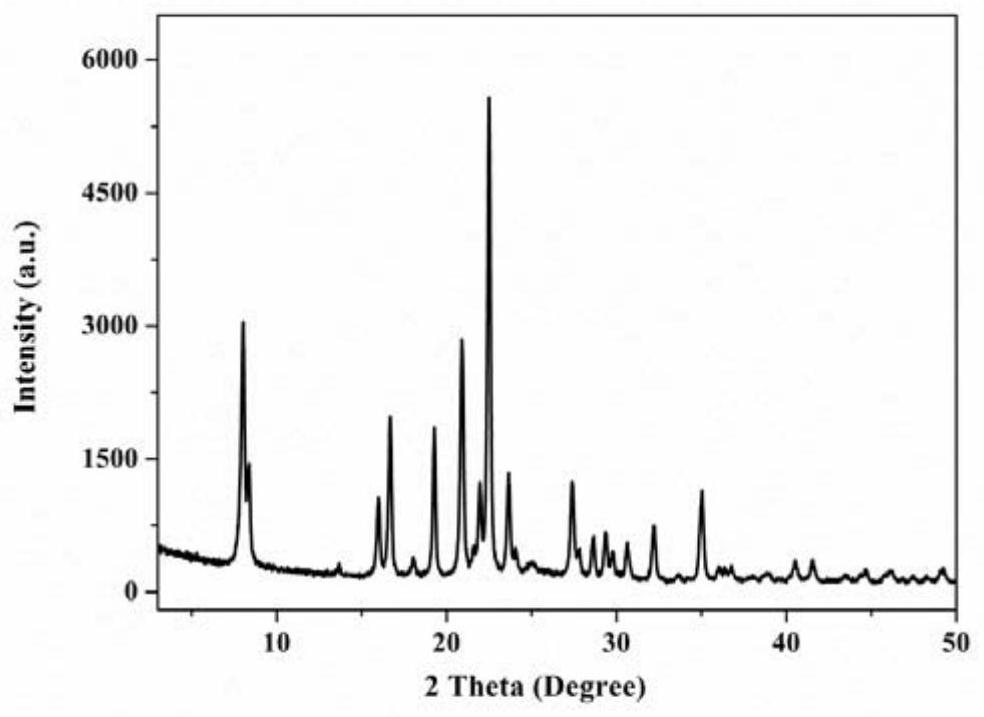

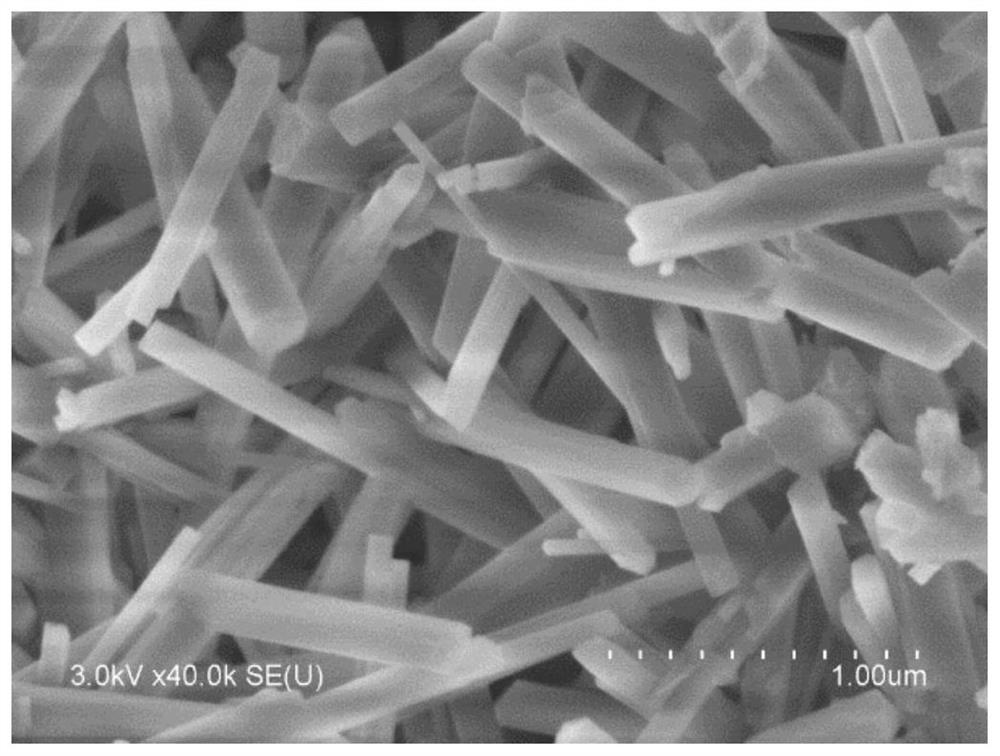

[0082] The mixture was charged into a stainless steel reactor and crystallized at 170°C for 14 days. After crystallization, filter, wash, and dry in an oven at 110°C to obtain the XRD spectrum of the molecular sieve as shown in figure 1 As shown, it is an ATS silicon-aluminum molecular sieve; the SEM image of the molecular sieve is as follows f...

Embodiment 2

[0086] With 13.339 grams of deionized water, 11.974 grams of organic structure directing agent 4-pyrrolidinylpyridine, 20.226 grams of silica sol (containing SiO 2 40% by weight), 5.5007 grams of aluminum isopropoxide, and 6.063 grams of hydrofluoric acid (containing 40% by weight of HF) were uniformly mixed, and after stirring at room temperature for 2 hours, the raw material solution was stirred at 65° C., and 18.44 grams of water were evaporated to obtain Mixture, final material ratio (mol ratio) is:

[0087] al 2 o 3 / SiO 2 =0.10

[0088] 4-Pyrrolidinylpyridine / SiO 2 =0.6

[0089] F / SiO 2 =0.9

[0090] h 2 O / SiO 2 =4.4

[0091] The mixture was charged into a stainless steel reactor and crystallized at 160°C for 12 days. After crystallization, filter, wash, and dry in an oven at 110°C to obtain the XRD spectrum of the molecular sieve as shown in Figure 4 As shown, it is an ATS type silica-alumina molecular sieve; the SEM image of the molecular sieve is as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com