Method for preparing carbon fiber precursor by polymerization from mixed solvent

A technology of carbon fiber precursors and mixed solvents, which is applied in the direction of wet spinning, etc., can solve the problems that the spinnability of carbon fiber precursors cannot be improved, it is not conducive to the preparation of high-performance carbon fiber precursors, and it cannot meet the requirements of T700 carbon fibers. Conducive to environmental protection, small fineness, and the effect of improving structural regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

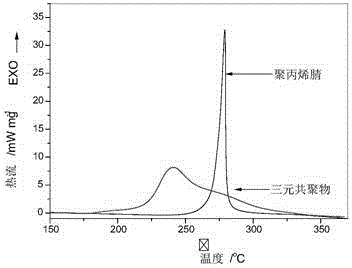

Image

Examples

Embodiment 1

[0029] (1) Acrylonitrile, 3-carboxy-3-butenamide, and dimethyl itaconate are mixed evenly at a mass ratio of 98.2:1.5:0.3 and then added to the reactor (total concentration of mixed monomers is 16%), and then methyl Sulfoxide / deionized water (60 / 40wt / wt), finally add azobisisobutyronitrile (accounting for 0.7wt% of the total mass of mixed monomers), react at 60°C for 8 hours, and the prepared polyacrylonitrile molecular weight is 4.8×10 5 g / mol, the molecular weight distribution is 2.23. The above-mentioned polymer was dissolved, defoamed, and filtered (0.8 μm filter material) to obtain a spinning dope.

[0030] (2) step (1) is obtained spinning dope through dry jet wet spinning, the distance of air section is 10cm, and the temperature of air section is 10 ℃, and relative humidity is 65%, the dimethyl sulfoxide in coagulation bath The content is 60wt%, the temperature of the coagulation bath is 0 °C, and the coagulation time is 1 min; the first-level hot water (75 °C) draws ...

Embodiment 2

[0033] (1) Acrylonitrile, 3-carboxy-3-butenamide, and dimethyl itaconate are mixed evenly at a mass ratio of 98.2:1.5:0.3 and then added to the reactor (total concentration of mixed monomers is 16%), and then methyl Sulfoxide / deionized water (60 / 40wt / wt), finally add azobisisobutyronitrile (accounting for 0.6wt% of the total mass of mixed monomers), react at 60°C for 8 hours, and the prepared polyacrylonitrile molecular weight is 5.6×10 5 g / mol, the molecular weight distribution is 2.30. The above-mentioned polymer was dissolved, defoamed, and filtered (0.8 μm filter material) to obtain a spinning dope.

[0034] (2) Step (1) is obtained spinning dope through dry-spray wet spinning, and the distance of air section is 10cm, and the temperature of air section is 10 ℃, and relative humidity is 65%, and the dimethyl sulfoxide in coagulation bath The content is 60wt%, the temperature of the coagulation bath is 0 °C, and the coagulation time is 1 min; the first-level hot water (75 ...

Embodiment 3

[0036] (1) Acrylonitrile, 3-carboxy-3-butenamide, and dimethyl itaconate are mixed uniformly at a mass ratio of 98.7:1.0:0.3 and then added to the reactor (the total concentration of mixed monomers is 16%), and then methyl Sulfoxide / deionized water (60 / 40wt / wt), finally add azobisisobutyronitrile (accounting for 0.7wt% of the total mass of mixed monomers), react at 60°C for 8 hours, and the prepared polyacrylonitrile molecular weight is 5.2×10 5 g / mol, the molecular weight distribution is 2.24. The above-mentioned polymer was dissolved, defoamed, and filtered (0.8 μm filter material) to obtain a spinning dope.

[0037] (2) step (1) is obtained spinning dope through dry jet wet spinning, the distance of air section is 10cm, and the temperature of air section is 10 ℃, and relative humidity is 65%, the dimethyl sulfoxide in coagulation bath The content is 60wt%, the temperature of the coagulation bath is 0 °C, and the coagulation time is 1 min; the first-level hot water (75 °C)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com