Exposure apparatus and device manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

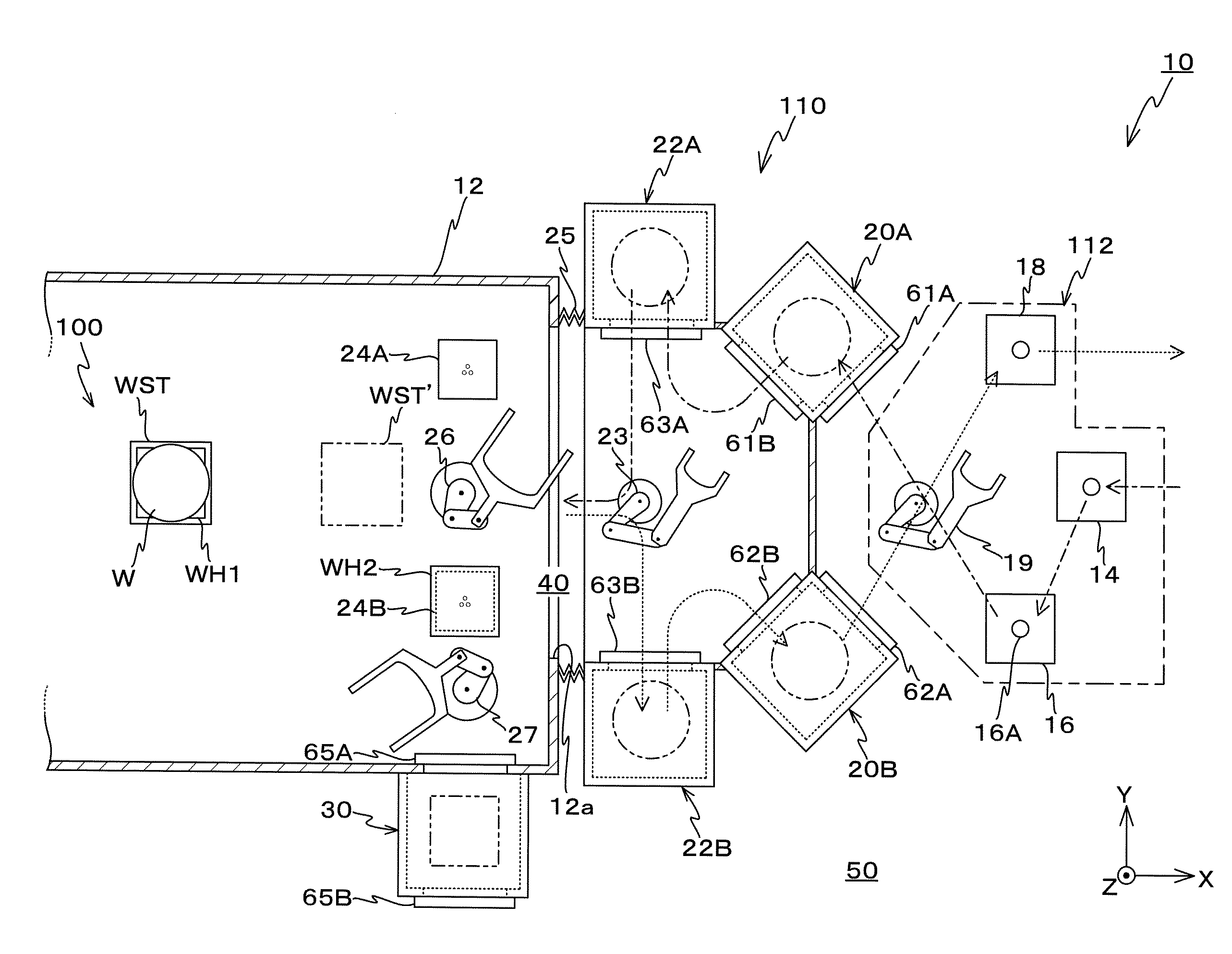

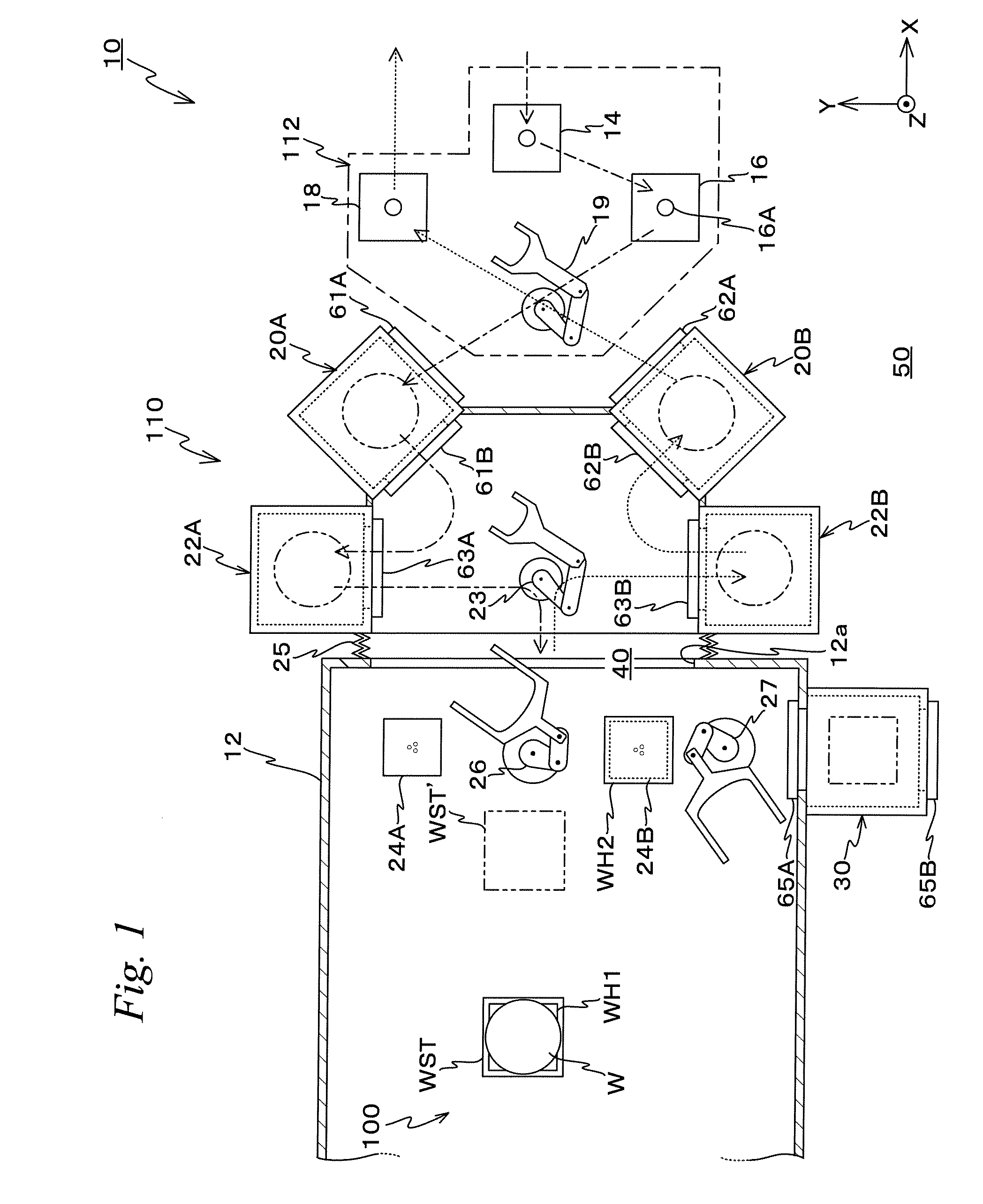

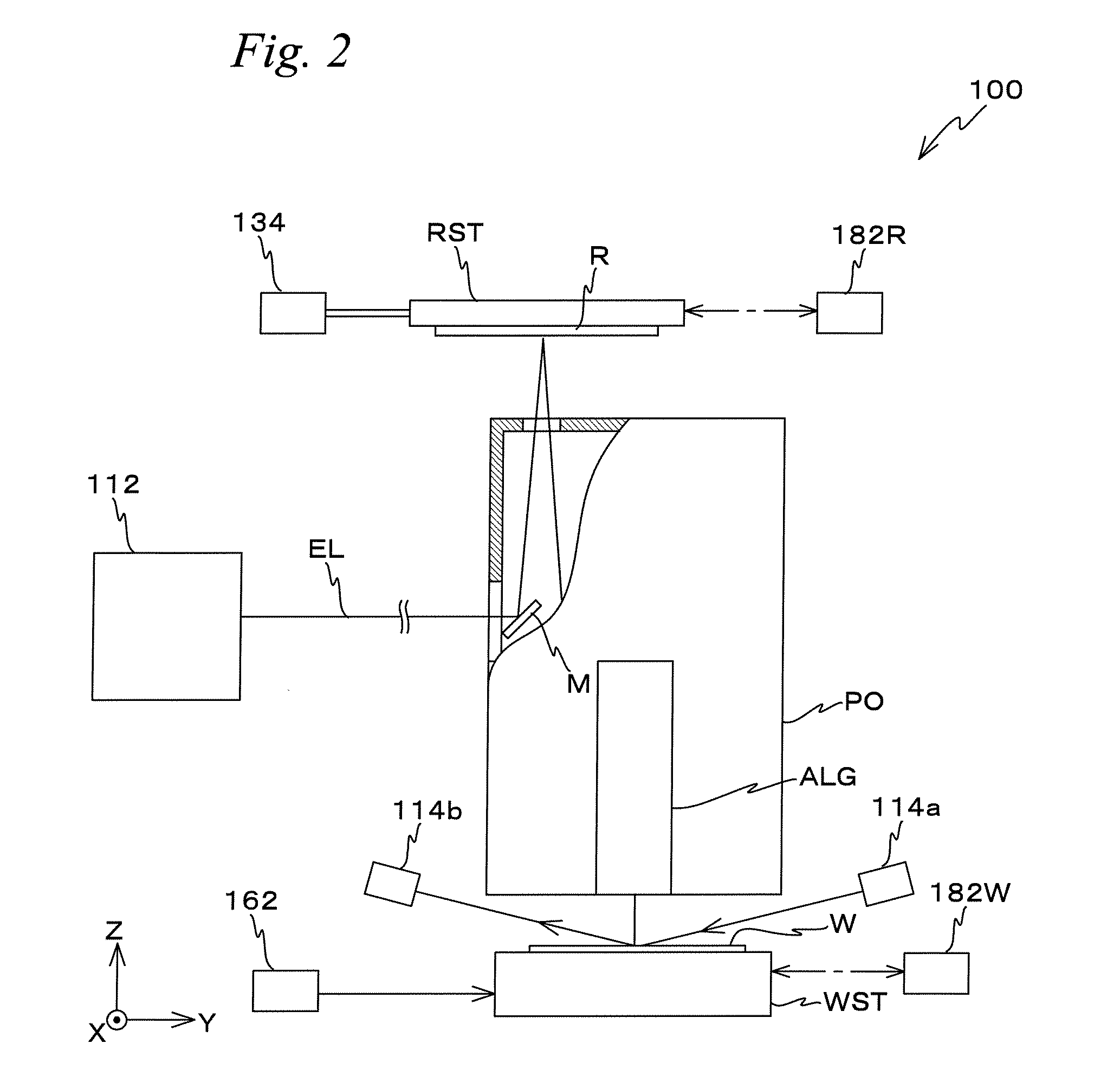

[0019]Hereinafter, an exposure apparatus 10 related to an embodiment of the present invention will be described, referring to FIGS. 1 to 6B.

[0020]FIG. 1 shows a planar view of a schematic configuration of exposure apparatus 10 related to the embodiment. Exposure apparatus 10 is equipped with an atmospheric carrier system 112 placed in an atmospheric pressure space 50, a vacuum carrier system 110 placed on the −X side of atmospheric carrier system 112, and a main body chamber 12 placed on the −X side of vacuum carrier system 110.

[0021]Between vacuum carrier system 110 and an opening 12a section of main body chamber 12, a bellows 25 is arranged, and an enclosed space (airtight space) 40 is formed by main body chamber 12, vacuum carrier system 110, and bellows 25. The inside of enclosed volume 40 is to be in a vacuum state by a vacuum pump (not shown). In the description below, this space 40 shall be referred to as a “vacuum space 40”. Further, because vacuum carrier system 110 and mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com