Silicon wafer linear exchange device and method

An exchange device, straight line technology, applied in the direction of exposure device, transportation and packaging, conveyor objects, etc. in the photoengraving process, which can solve the problems of low precision and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

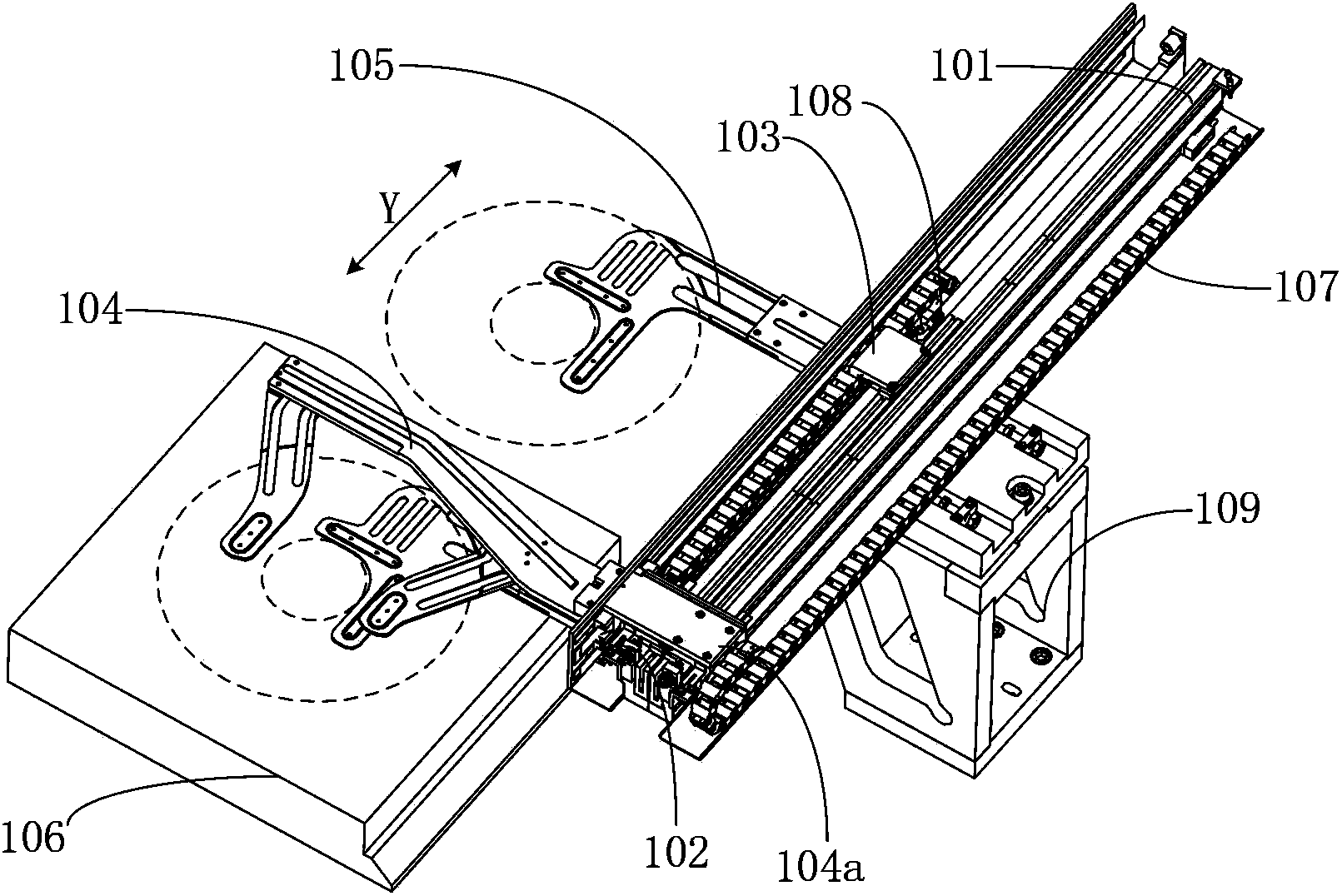

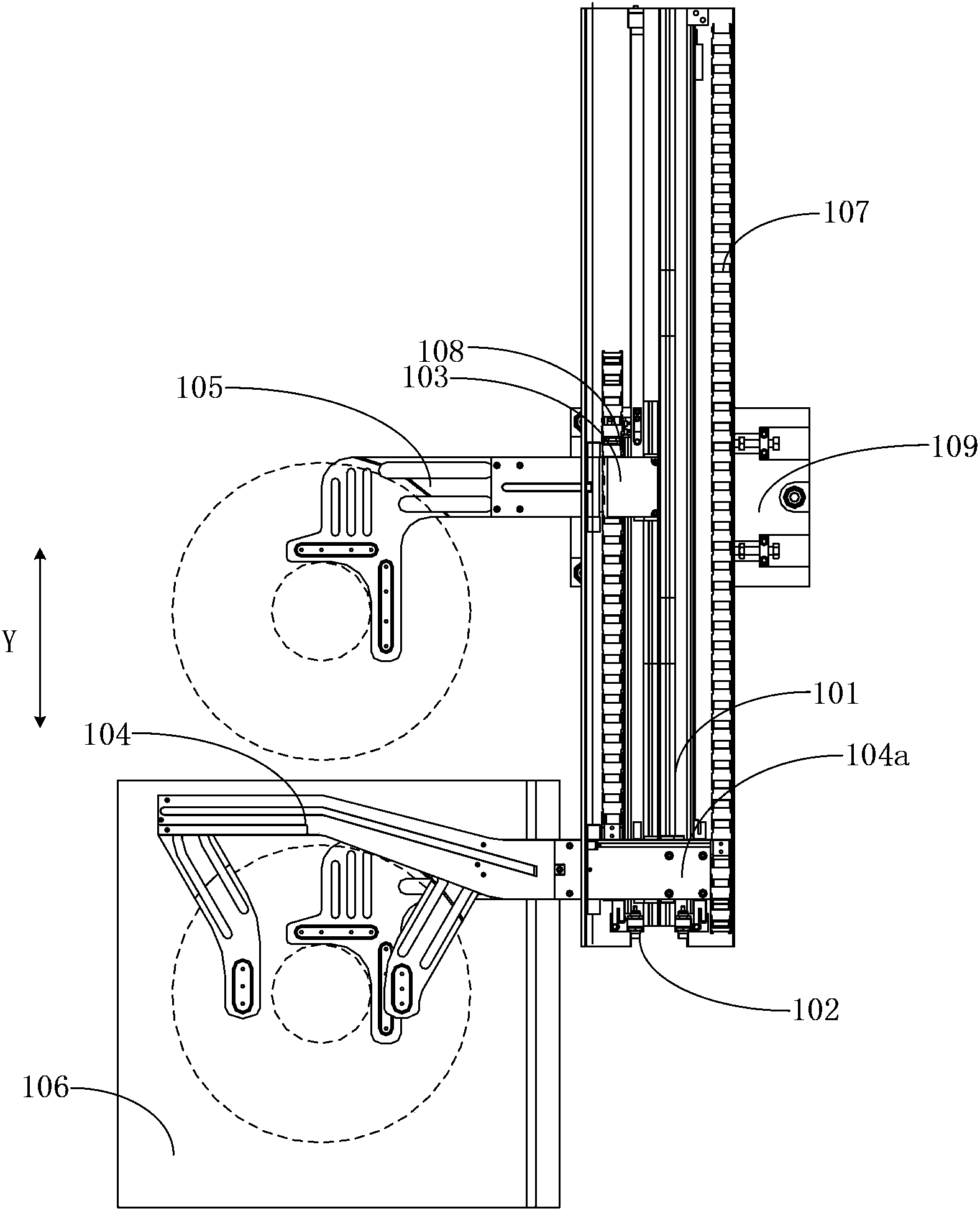

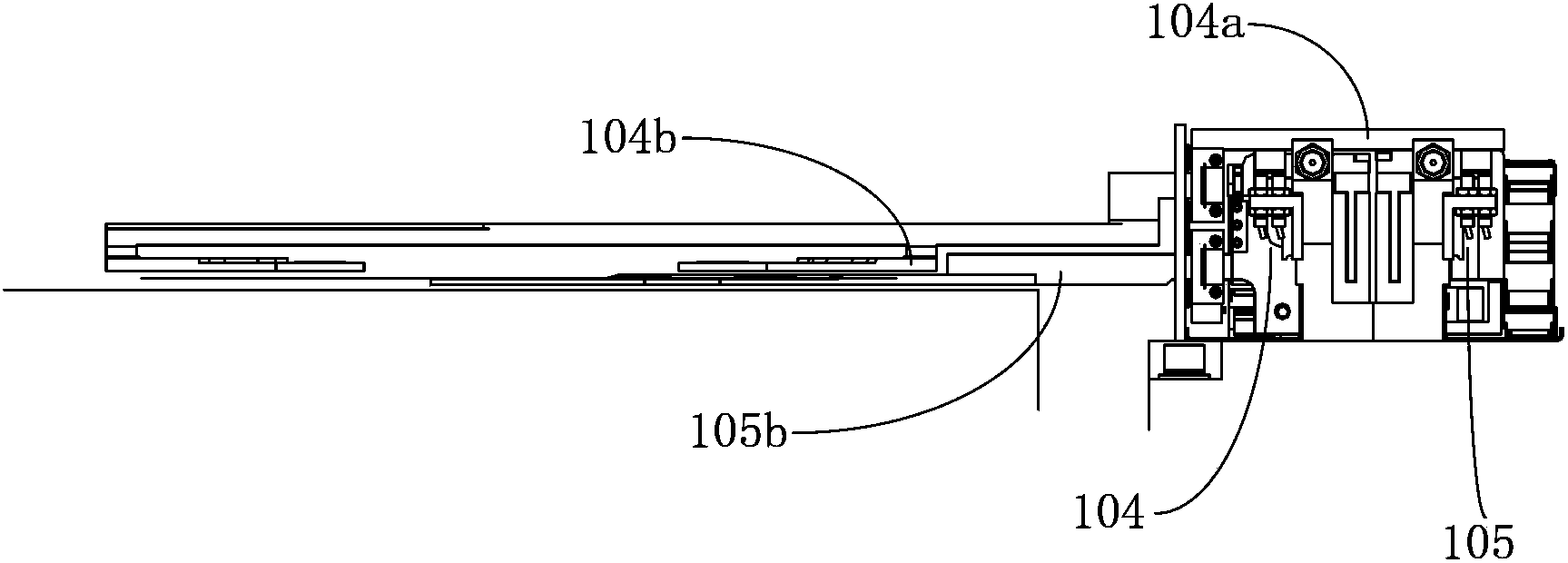

[0036] The silicon chip linear exchange device provided by the present invention is used to transfer materials between the workbench and the external device, and its structure is as follows: figure 1 and figure 2 As shown, the guide rail 101 is included, specifically, the guide rail 101 is a single wide linear guide rail; the first slider 102 and the second slider 103 arranged on the guide rail 101, the first and second The sliders 102, 103 are capable of staggered reciprocating motion along the guide rail 101; the first mechanical arm 104, the first mechanical arm 104 is connected to the first slider 102 through the mechanical arm adapter 104a; and the second mechanical arm 105, the second mechanical arm 105 is connected to the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com