High-altitude oil exchange system for gearbox of wind driven generator and control method of high-altitude oil exchange system

A technology for wind turbines and gearboxes, which is applied to wind turbines, wind energy power generation, engines, etc., can solve problems such as difficulty in realization, oil quality cannot be guaranteed, oil cleanliness cannot be guaranteed, etc., to avoid human error. Effects of Operational Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

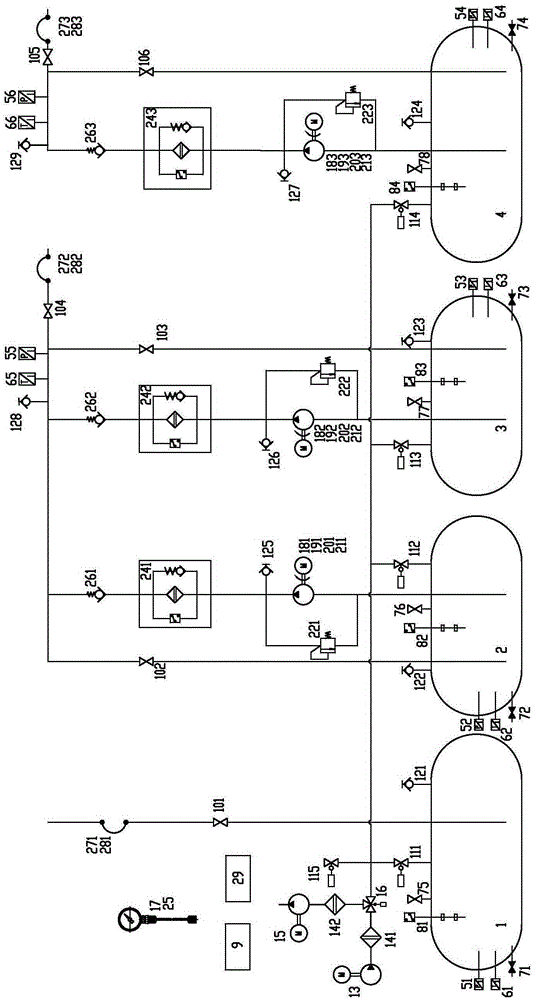

[0113] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a high-altitude oil change system for a wind turbine gearbox includes a waste oil discharge module, a flushing oil module, a cleaning oil module, a new oil module, an auxiliary power system, and an electric control system 29;

[0114] The waste oil discharge module includes a waste oil tank 1, a rubber hose A281 and a quick-change joint A271. The waste oil tank 1 is equipped with a pressure sensor A51, a temperature sensor A61, a liquid level relay A81, a ball valve A71, a ball valve E75 and The pressure measuring joint A121, the waste oil tank 1 is connected to the quick-change joint A271 through the ball valve I101 and the rubber hose A281; the waste oil tank 1 is also connected to one end of the electric valve A111;

[0115]The flushing oil module includes a flushing oil tank 2 and a gear pump A211, and the flushing oil tank 2 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com