Machining centre

A machining center and process technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of time-consuming and low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

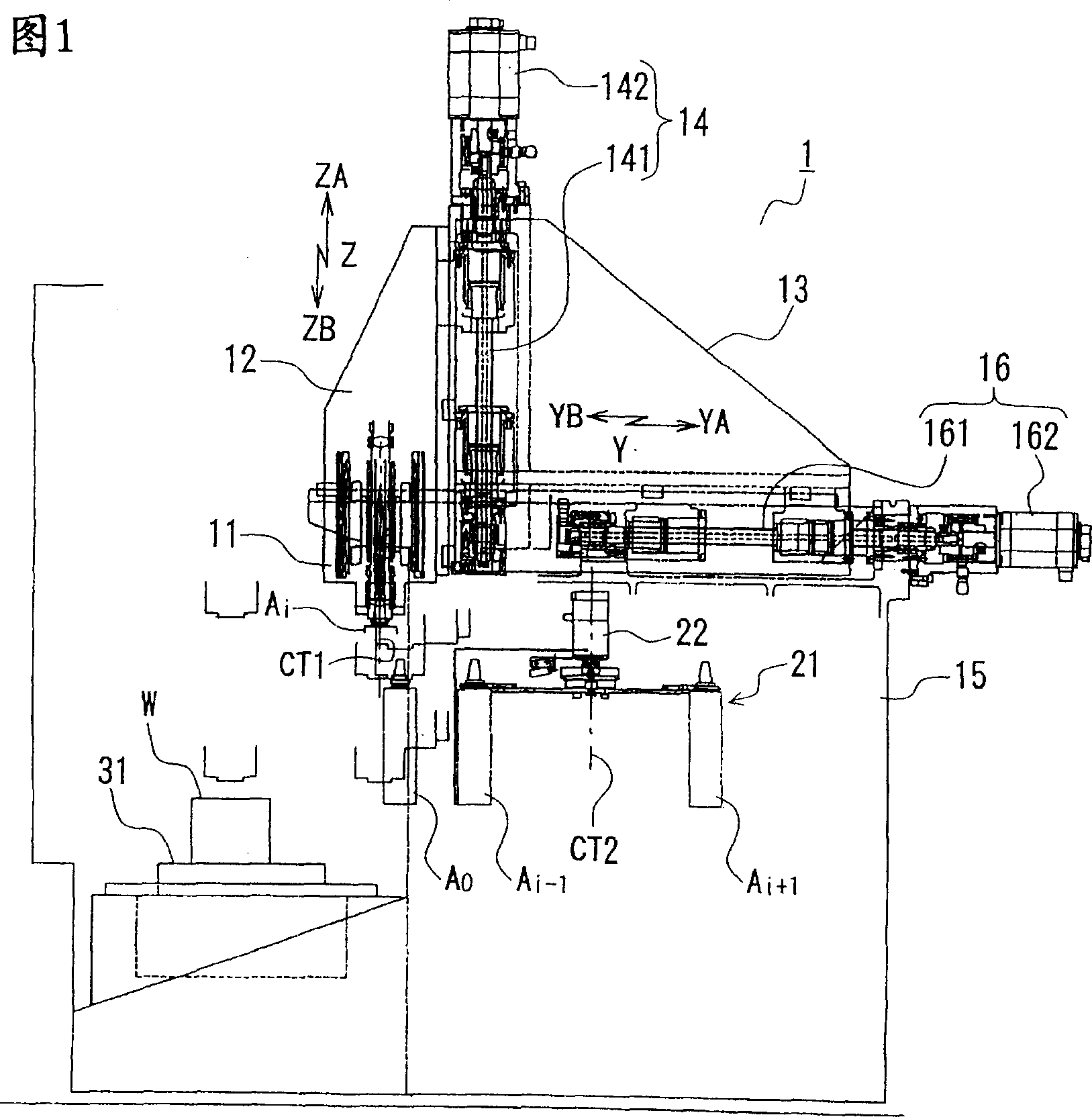

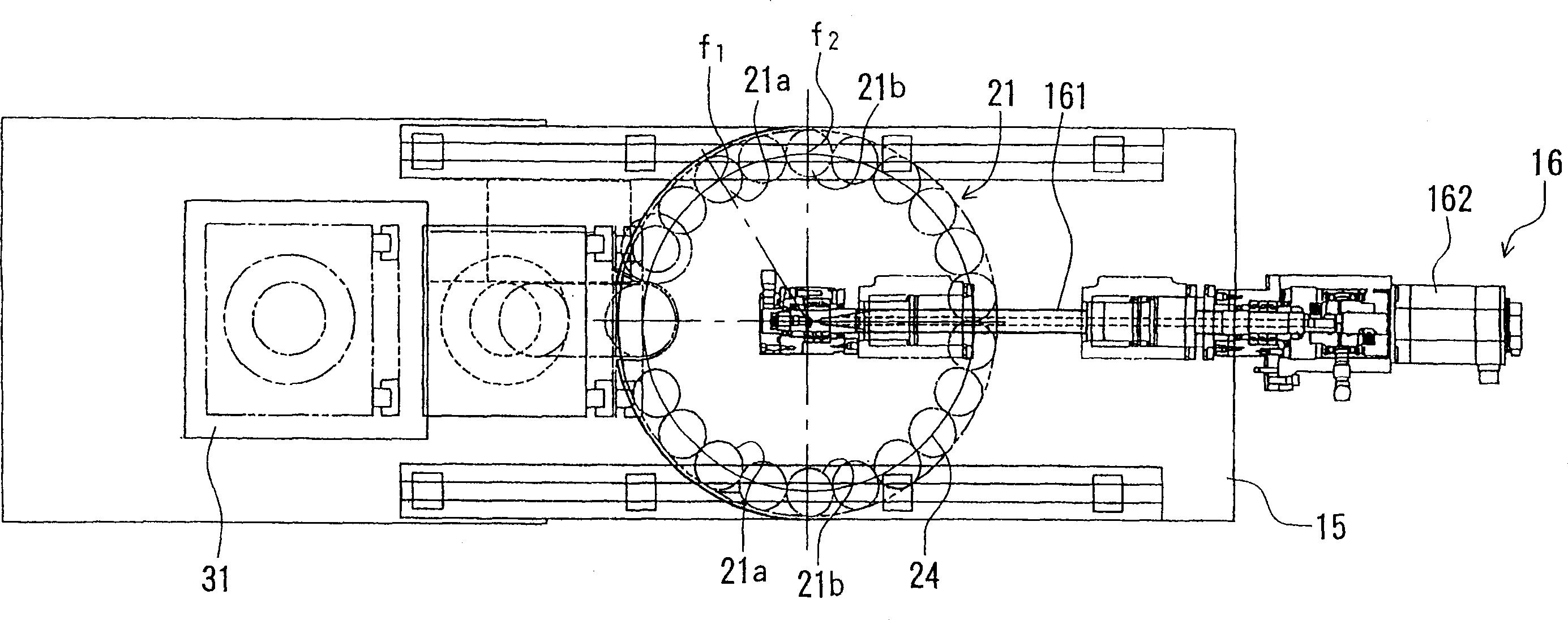

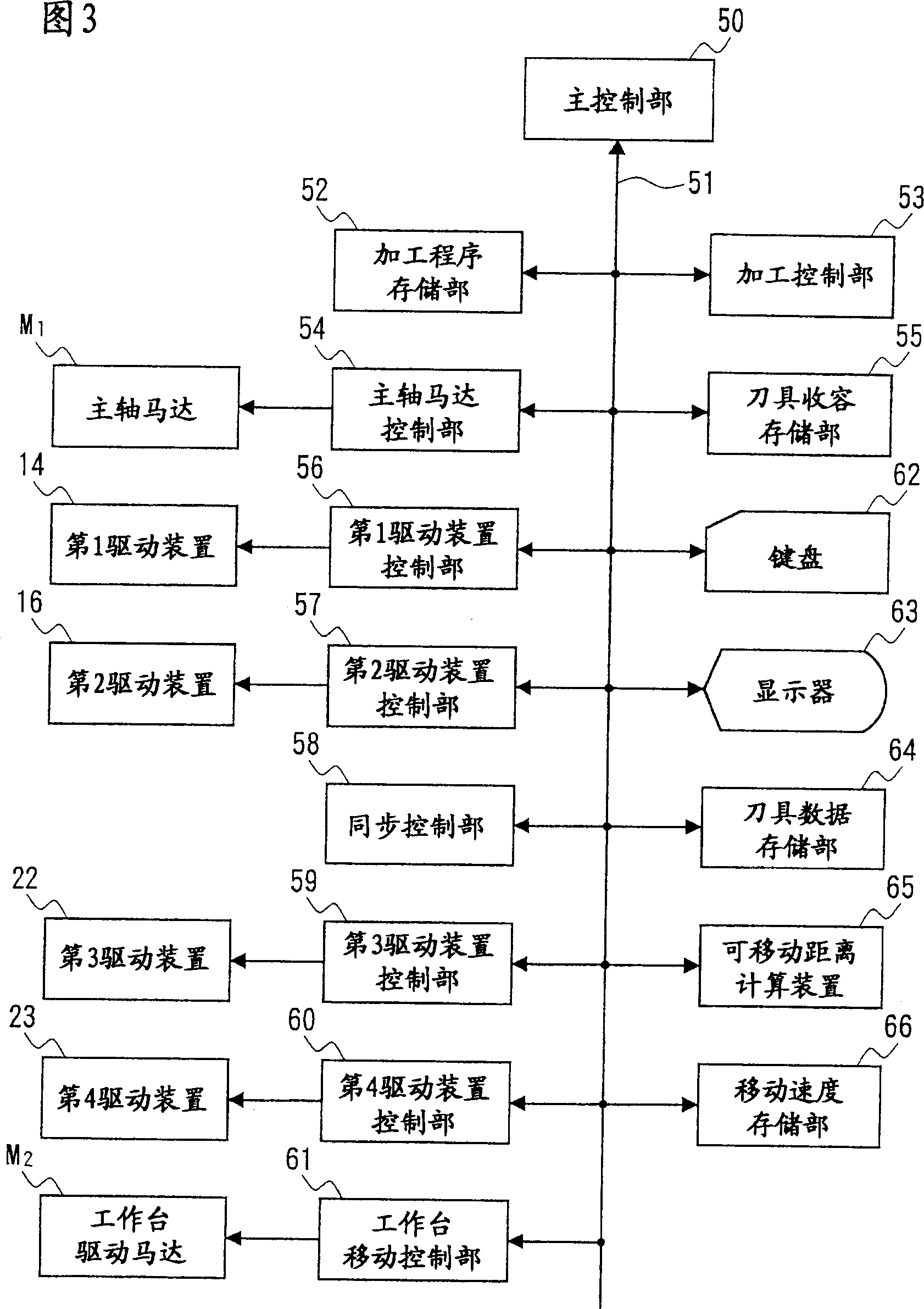

[0031] Fig. 1 is a side view showing an example of the structure of the machining center in the present invention; figure 2 It is a plan view showing an example of the structure of the machining center in the present invention; FIG. 3 is a block diagram showing an example of the structure of the control device of the machining center in the present invention; A schematic diagram of the state in which the tool is removed and stored in the tool magazine; Figure 5(a)-(e) is a schematic diagram showing the state of the tool magazine moving; Figure 6 (a) to (e) are schematic diagrams showing a state in which a tool is mounted on a spindle.

[0032] As shown in FIG. 1, a machining center 1 in the present invention has a spindle 11 that detachably supports a tool Ai (only the upper part is shown), and a plurality of tool holders for accommodating the tools Ai-1 and Ai+1. (refer to figure 2 In the label 21a, 21b) tool magazine 21. As shown in Figure 4 (a), in the tool magazine 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com