Evaporating heat exchanger with moistened surface

A heat exchanger, evaporative technology, applied in the field of surface wetting evaporative heat exchanger, can solve the problems of difficult maintenance, unstable structure, complex structure, etc., achieve uniform control of quality, heat exchange effect saving, evaporation The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

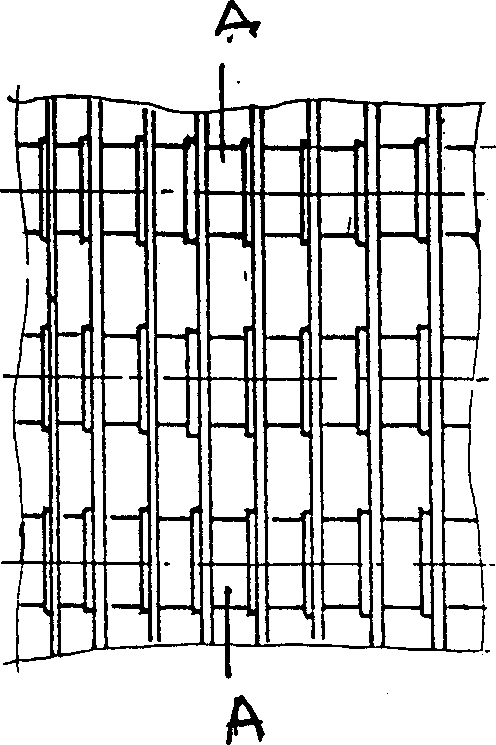

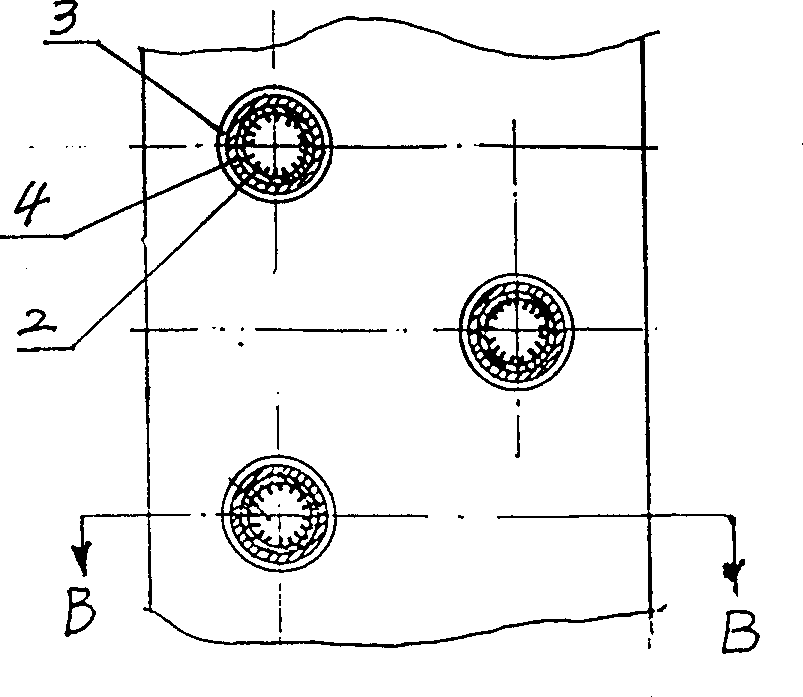

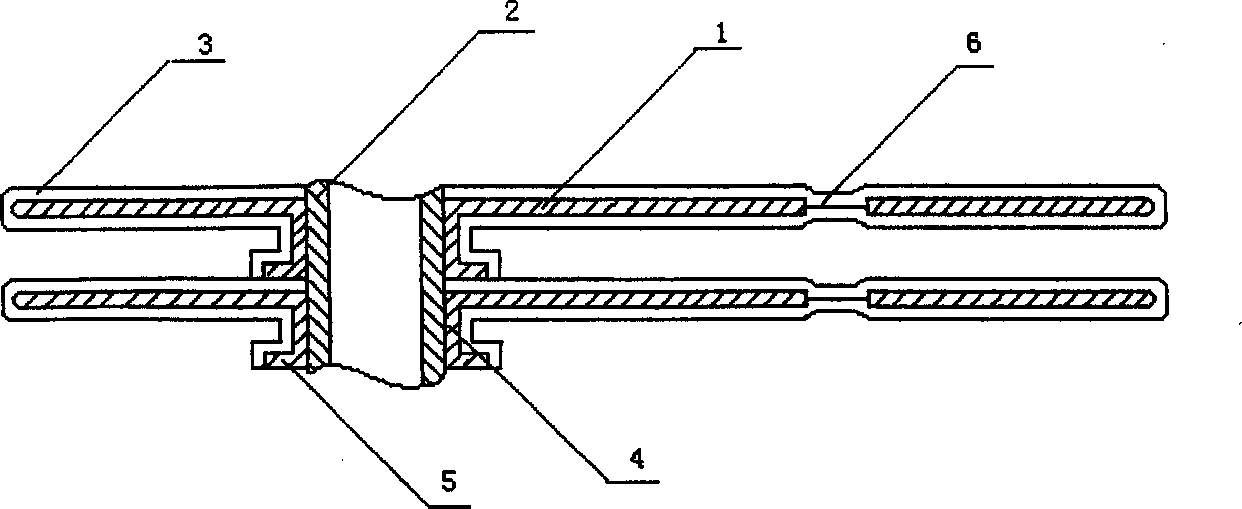

[0017] The following will be further described in conjunction with the accompanying drawings. The surface wetting evaporative heat exchanger of the present invention includes a fan, a water spray device, and a plurality of metal cooling fins 1 parallel to each other. A plurality of metal tubes 2 are equipped with non-woven fabrics 3 on the outer surface of the metal heat sink 1; and one side of each heat sink 1 is made with a convex tube leading to the adjacent heat sink 1 and covering the metal tube 2 4. The end of the convex tube 4 is formed with a blue plate 5 extending to the sides, and the outer surfaces of the convex tube 4 and the blue plate 5 are also equipped with non-woven fabrics 3 . The heat sink 1 is formed with a plurality of evenly distributed circular anti-falling holes 6 with a diameter of 4-6 mm, and the non-woven fabrics 3 on both sides of the circular anti-falling holes 6 are directly connected together. The metal pipe 2 is preferably a copper pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com