Circulating rare earth wastewater comprehensive treatment system

A comprehensive treatment and circulation technology, applied in the field of circulation rare earth wastewater comprehensive treatment system, can solve the problems of slow evaporation speed, small area, vacuum pump damage, etc., and achieve the effect of increasing evaporation surface area, improving distillation efficiency and avoiding evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

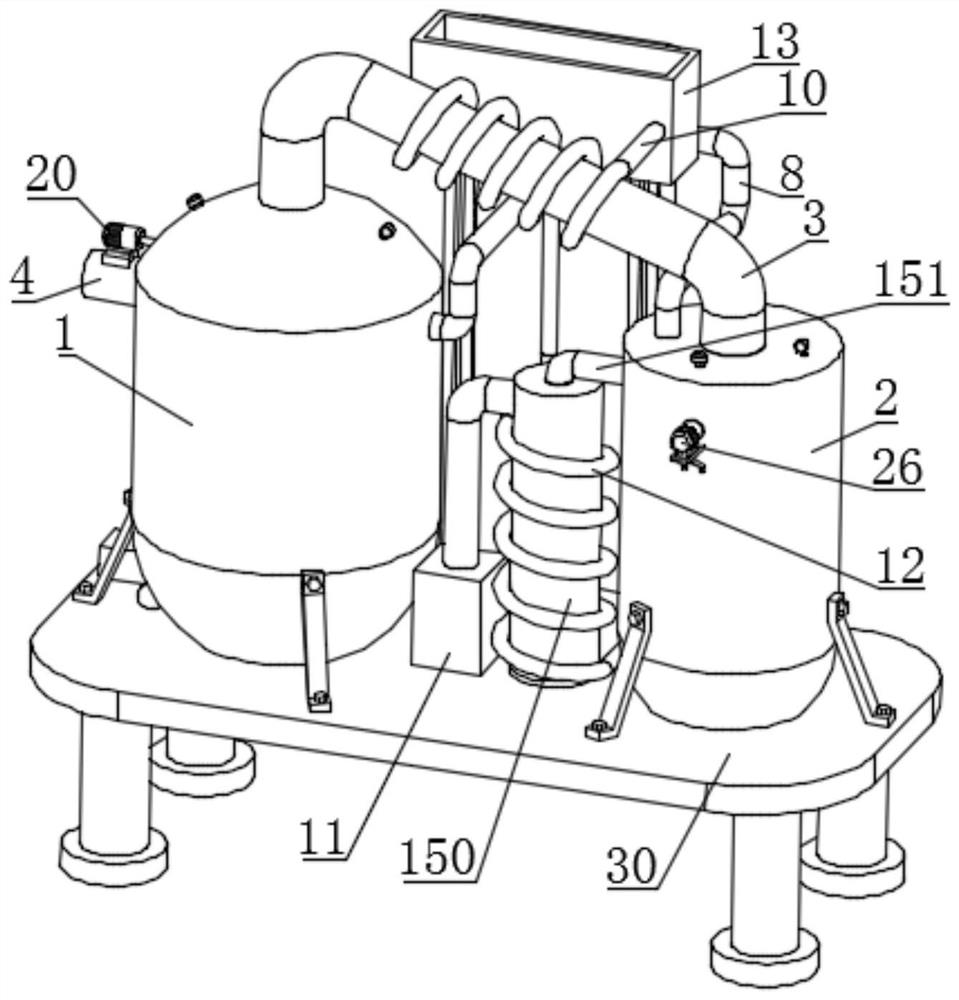

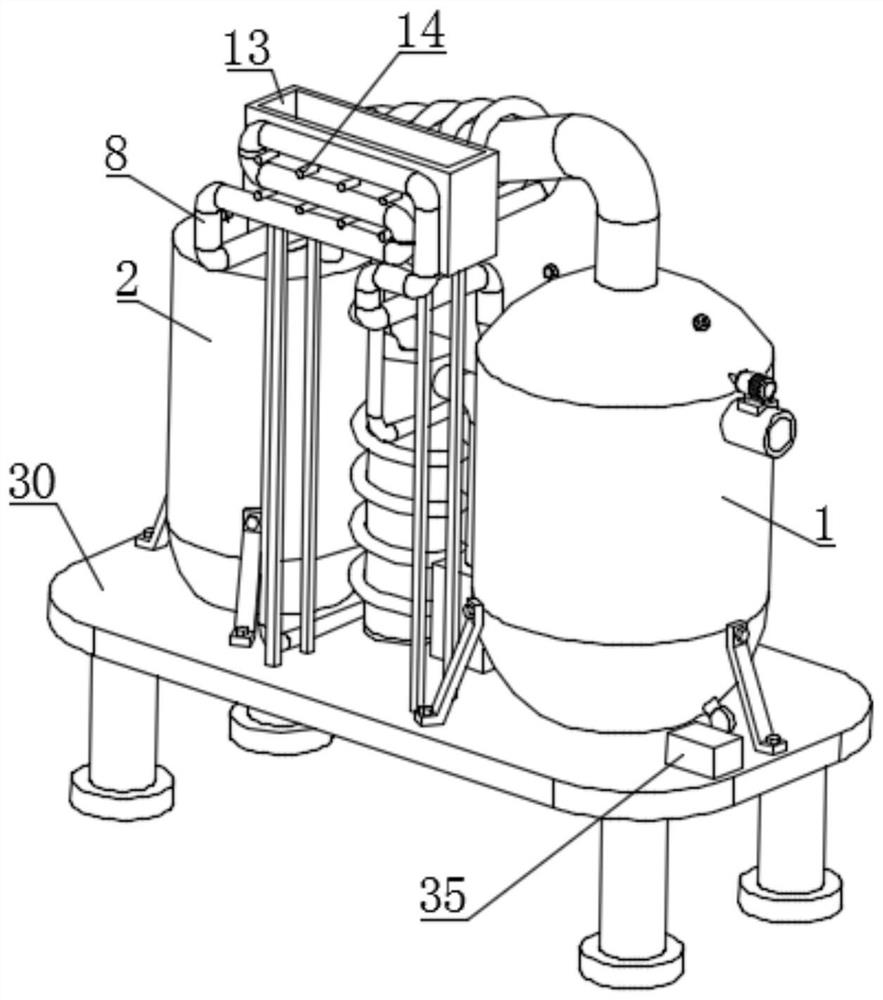

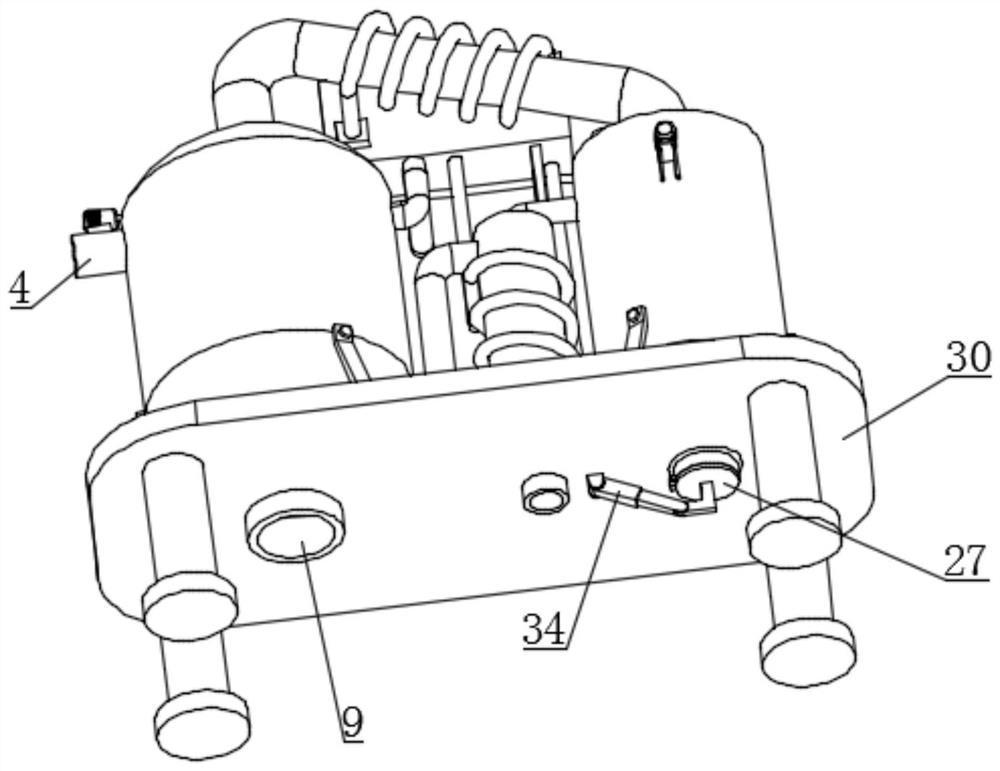

Embodiment 1

[0033] Embodiment 1, the present invention provides a kind of technical scheme: a kind of circulating type rare earth wastewater comprehensive treatment system, comprises distillation kettle 1 and collection tank 2, and pressure relief valve is installed on distillation kettle 1 and collection tank 2 and is used for detecting distillation Pressure gauges for the internal pressure of the still 1 and the collection tank 2, and a pH detection module 31 for detecting acidic wastewater is also installed inside the still 1, and the pressure relief valve can be opened when the distillation is completed, so that the inside of the still 1 and the collection tank 2 The air pressure in the still can be restored to normal, so that the distillation raffinate and condensate can be discharged better. The pH detection module 31 can detect the pH value of the acidic wastewater inside the still 1 in real time, so that the distillation process can be accurately judged, and the still still 1 can be...

Embodiment 2

[0044] Embodiment 2, the evaporation surface of the existing still 1 is the area of the liquid surface, so its evaporation rate is restricted by it, and there is a certain volume of barrier between the evaporation surface and the electric heating wire 5, so it is also easy to occur Therefore, in order to comprehensively utilize the inner surface of the still 1, the structure in the still 1 is changed on the basis of Embodiment 1.

[0045] Specifically, a lifting cylinder 36 that penetrates up and down is installed in the still 1, and the lifting cylinder 36 is installed and connected with the still 1 by surrounding accessories. The turbine 37 is connected to the rotating shaft 6, and the lifting cylinder 36 sets Connected to the outside of the turbine 37, the turbine 37 can play the role of agitating paddles, and can also cooperate with the lifting cylinder 36 to remove the upper end of the lifting cylinder 36 from the material and liquid lift. The upper end of the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com