Micro-combustor for metal mesh heat storage and flame stabilization and combustion method thereof

A metal grid and micro-combustion technology, which is applied in the direction of combustion methods, burners for evaporating liquid fuels, burners, etc., can solve the problems of difficult continuous, high-efficiency and stable combustion, difficulty in complete combustion of fuel, and short dimensional residence time. Stable and continuous, superior performance, convenient ignition process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

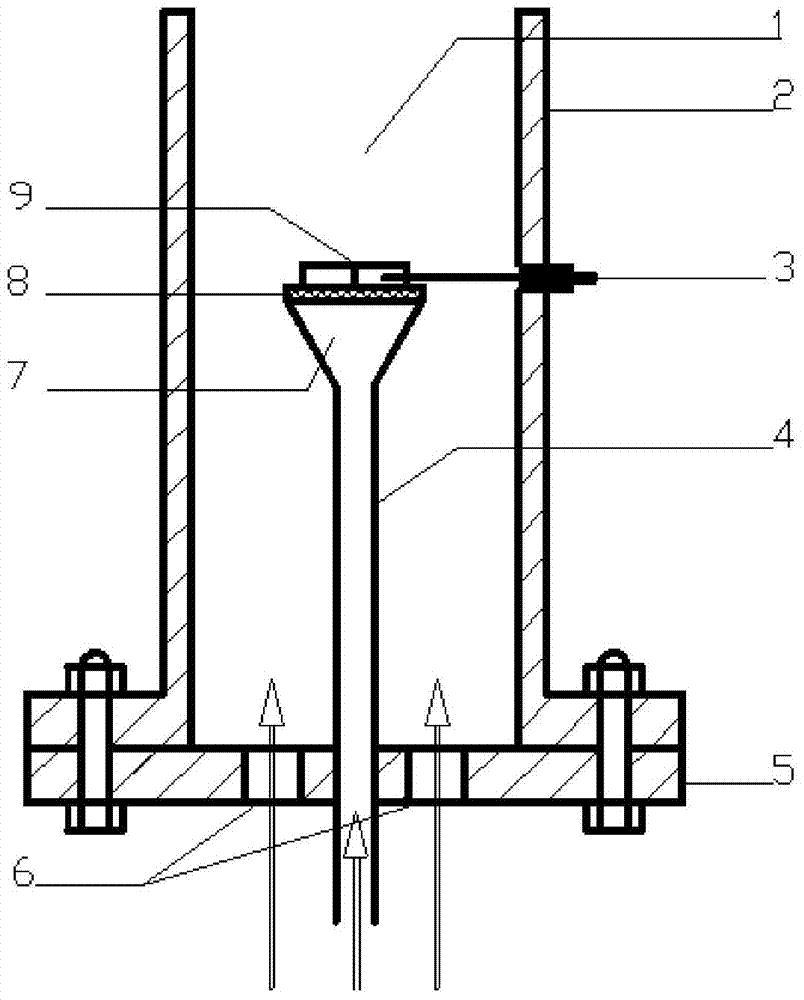

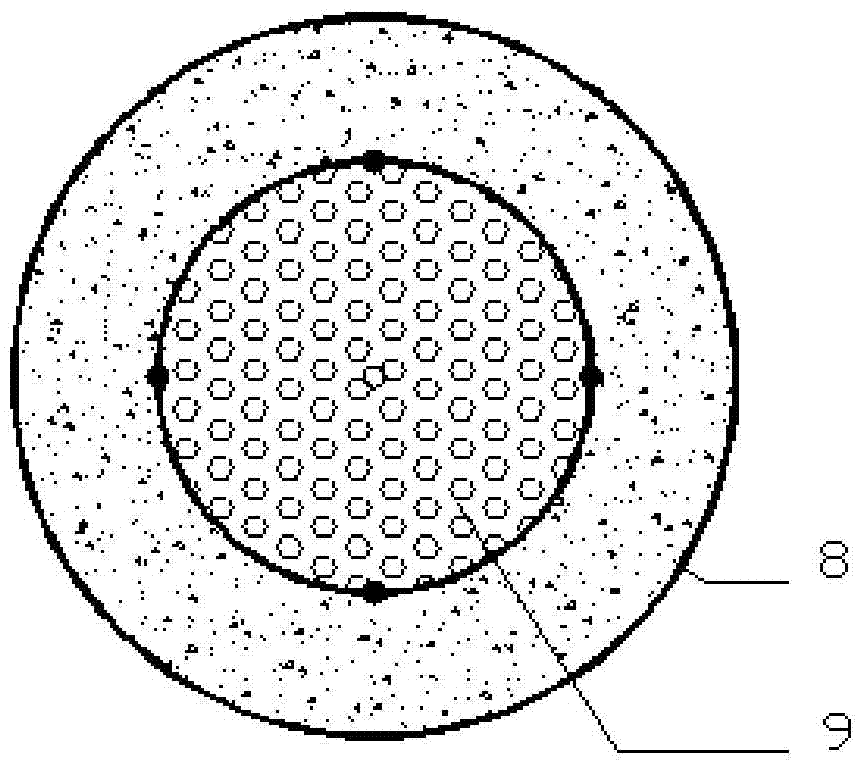

[0027] like figure 1 , 2 shown. The present invention is a miniature burner for thermal storage and stable flame of metal mesh, comprising a burner outer cylinder 2, a burner bottom plate 5 arranged at the bottom of the burner outer cylinder 2, and an igniter 3 arranged on the side wall of the burner outer cylinder 2 1. The burner arranged in the burner outer cylinder 2; the burner includes a hollow blunt body 7 whose longitudinal section shape is an inverted triangle, a porous medium disk 8 and a metal grid 9, and the porous medium disk 8 is placed in a hollow blunt body Above the body 7, the metal grid 9 is placed above the porous medium disc 8; the bottom of the hollow blunt body 7 is connected to the fuel channel 4, and the fuel channel 4 runs through the burner bottom plate 5 to connect to the external liquid fuel.

[0028] The liquid hydrocarbon fuel enters the fuel channel 4 through the micro-injection pump, and the oxidant from the high-pressure gas cylinder (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com