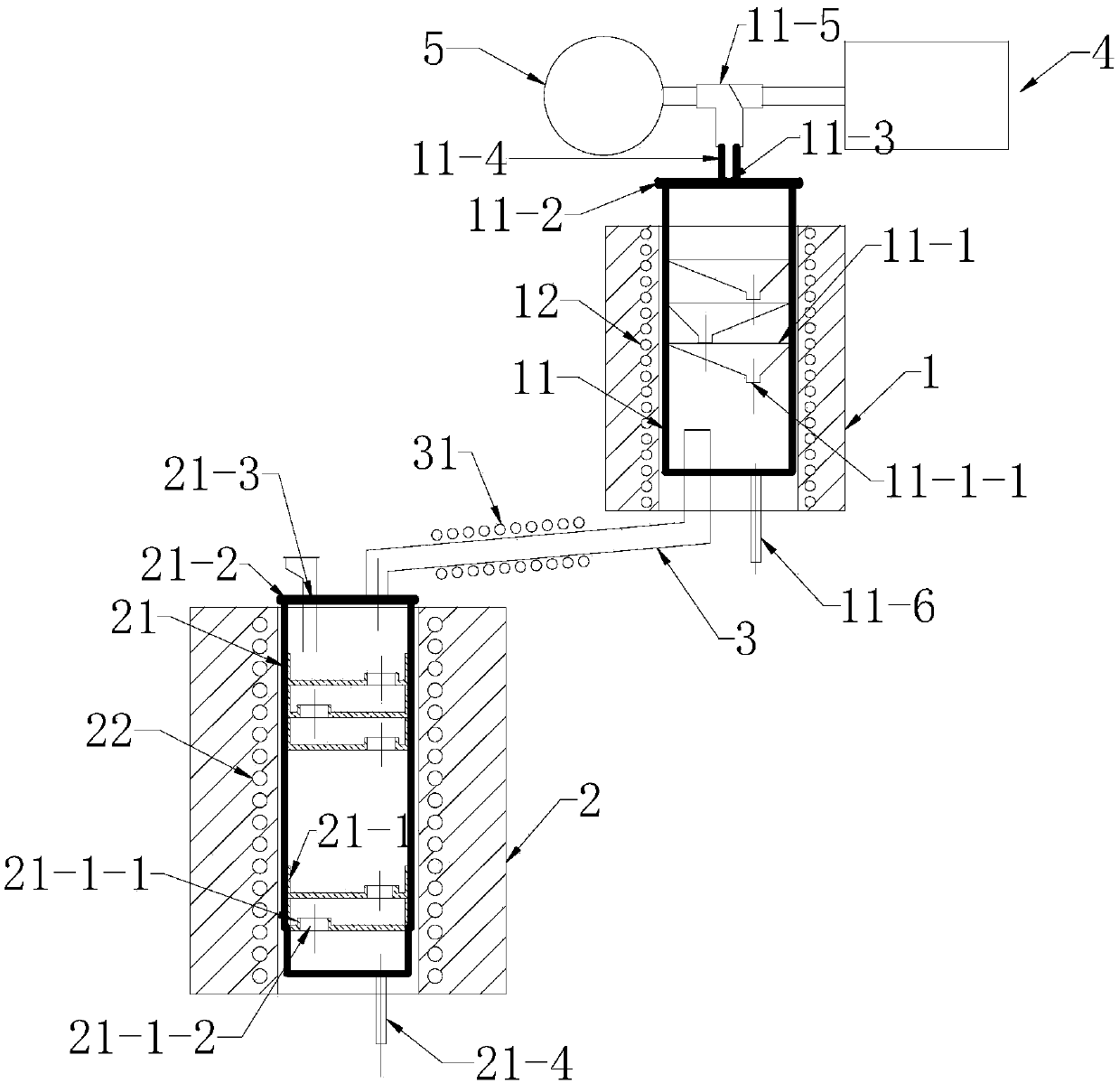

High-purity anaerobic selenium vacuum rectifying apparatus

A vacuum distillation and rectification technology, applied in vacuum distillation, element selenium/tellurium and other directions, can solve the problems of difficult to enlarge distillation equipment, limited production capacity, low production efficiency, etc., and achieve simple structure, convenient self-control, and improved production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

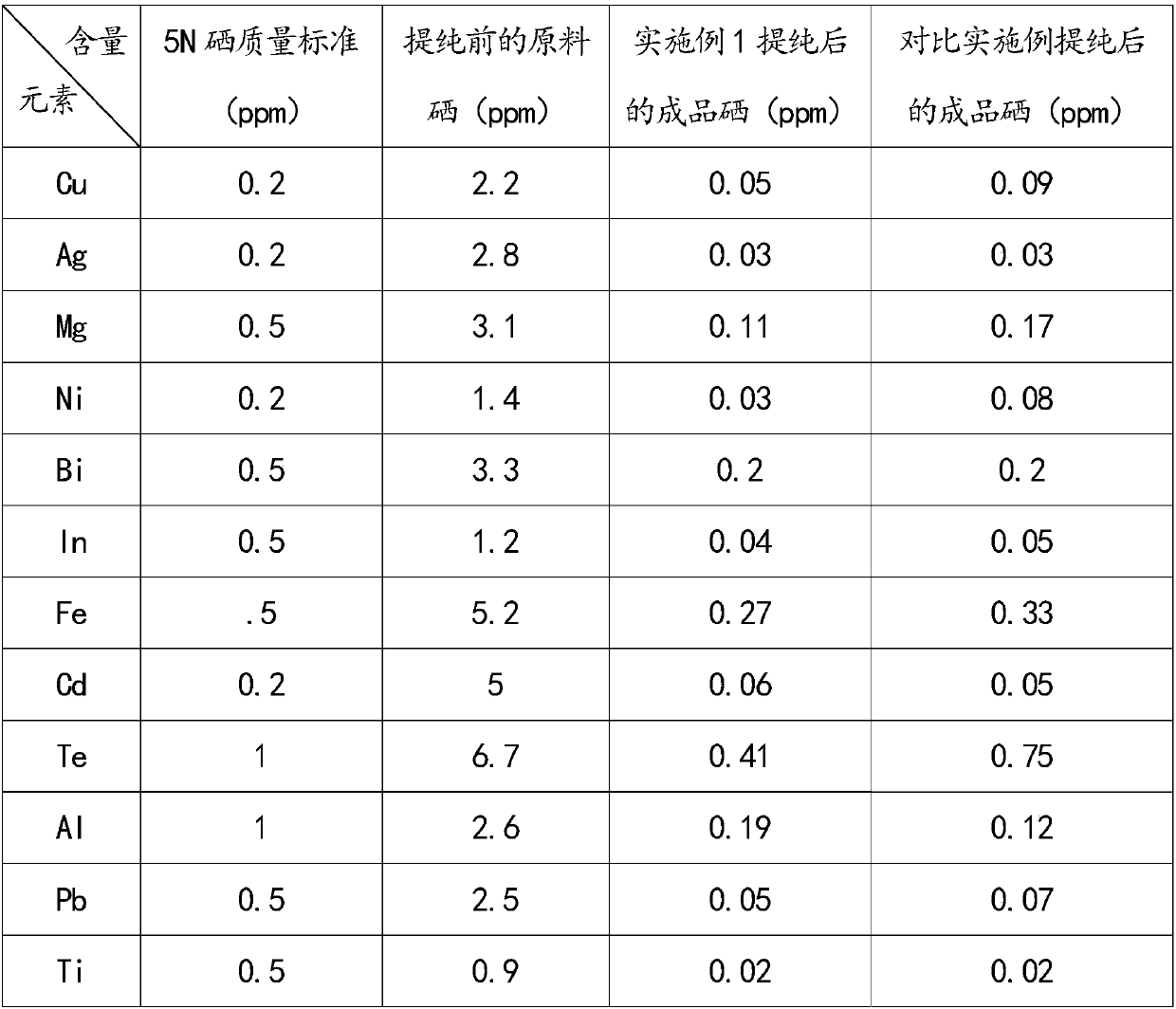

Embodiment 1

[0049] After the selenium raw material is crushed to 5-7 mm, it is placed in a quartz crucible and heated and melted into a liquid raw material selenium for use; the residual material outlet 21-4 of the rectification chamber 21 and the finished product outlet 11-6 of the condensation chamber 11 are sealed; After the distillation chamber is heated above 220°C, 10 kg of liquid selenium is added into the rectification chamber through the material inlet 21-3 at the upper end of the rectification chamber, and the liquid selenium raw material passes through the material overflow port 21-1-1 of the evaporator plate 21-1 Flow into each evaporator in turn from top to bottom. After the raw materials are added, the material inlet 21-3 is sealed, and the vacuum device 4 is turned on to evacuate until the vacuum degree in the rectification chamber reaches 10. -2 ~10 -4 After Pa, the rectification chamber 21, the steam pipe 3 and the condensation chamber 11 are heated, the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com