Negative pressure thermal evaporation equipment and technology of interventional activated carbon fiber boards

A technology of activated carbon fiber and thermal evaporation, applied in evaporation, evaporator accessories, evaporation separation and crystallization, etc., can solve the problems of insufficient evaporation area, easy fouling, high operating cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

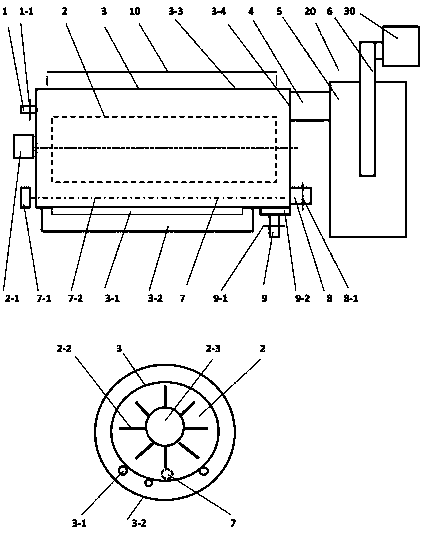

[0026]Use coal-fired flue gas wet desulfurization salty wastewater as raw material for solid-liquid separation, and send it to negative pressure thermal evaporation equipment with activated carbon fiber boards. According to the process of the present invention, finally collect clean water from the centrifugal cyclone gas-liquid separation assembly, The crystallized salt from the raw material is discharged from the discharge pipe (8); the leather desalted water is used as the raw material for solid-liquid separation, and after flocculation and precipitation to remove organic impurities such as oil, protein, etc., the salt-containing supernatant is sent to the negative side of the activated carbon fiber board. The autoclave evaporation equipment, according to the process of the present invention, finally collects clean water from the centrifugal cyclone gas-liquid separation assembly, and the crystallized salt from the raw material is discharged from the discharge pipe (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com