Full-automatic street lamp plate cutting and grinding device

A cutting and grinding, fully automatic technology, which is applied in the direction of grinding/polishing safety devices, grinding machines, grinding racks, etc., can solve problems such as poor performance, grinding wheel wear, and easy displacement, so as to improve the grinding effect and improve the Service life, effect of avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

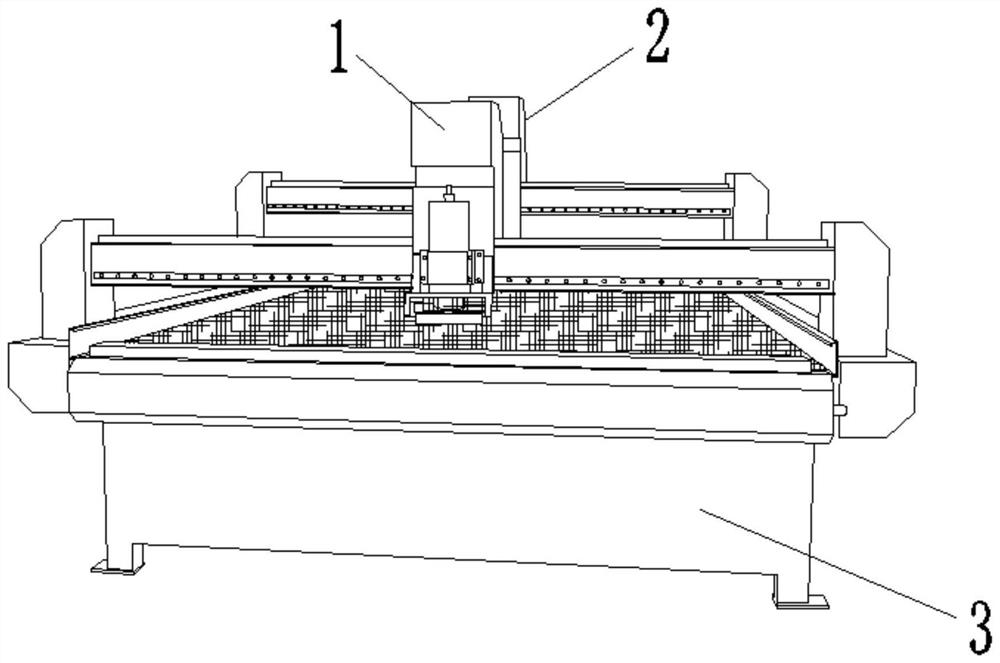

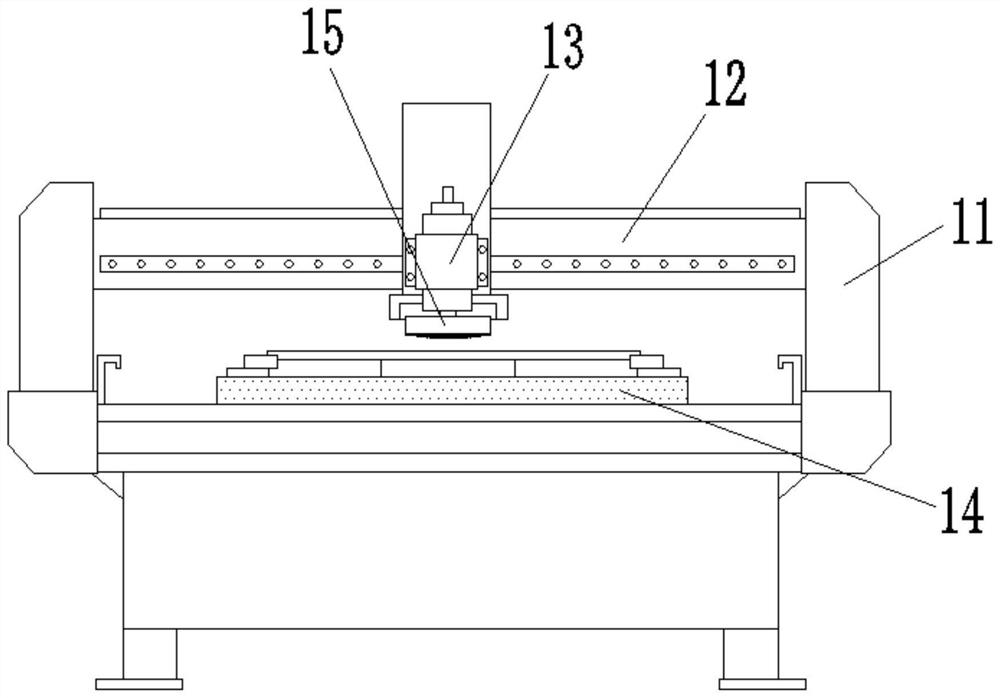

[0028] see Figure 1-5 :

[0029] The present invention provides a technical solution: a fully automatic cutting and grinding device for street lamp panels, including a grinding mechanism 1, a cutting mechanism 2 and a support base 3, the grinding mechanism 1 is installed on the top of the support base 3, and the cutting mechanism 2 is arranged on the back of the grinding mechanism 1 , the grinding mechanism 1 includes a support frame 11, a support cross bar 12, a main shaft 13, a workbench 14 and a grinding wheel 15, the support cross bar 12 is arranged above the support base 3, the support frame 11 is installed on the left and right sides of the support cross bar 12, and the main shaft 13 is arranged at the center of the support cross bar 12, the workbench 14 is installed at the top of the support base 3, and the grinding wheel 15 is arranged at the bottom of the main shaft 13.

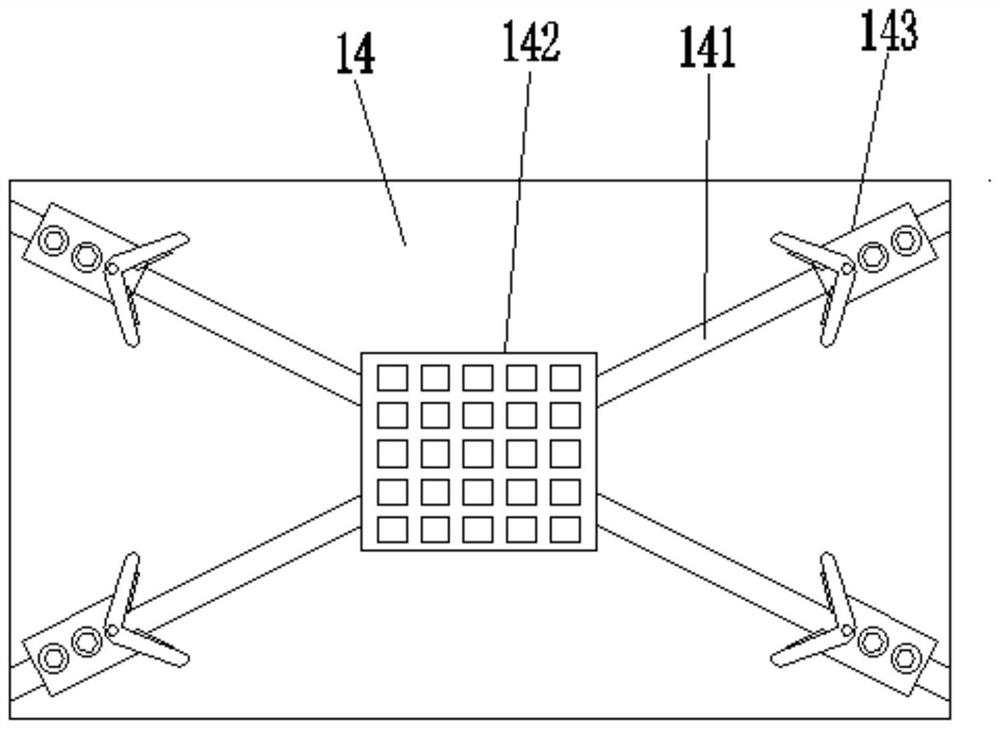

[0030] The workbench 14 includes a T-shaped slot 141, an electromagnetic chuck 142 and a positi...

Embodiment 2

[0033] see Figure 6-8 :

[0034] Grinding wheel 15 comprises running wheel 151, grinding plate 152, push rod 153, back-moving spring 154, rubber cover 155 and cooling mechanism 156, and running wheel 151 is arranged on grinding wheel 15 inside, and running wheel 151 two ends are all provided with chute, and grinding The plate 152 is arranged below the runner 151, the ejector rod 153 is installed on both ends of the grinding plate 152 and extends inside the chute, the top of the return spring 154 is fixedly connected to the top of the inner wall of the chute and the bottom is fixedly connected to the top of the ejector rod 153, and the rubber sleeve 155 The top is fixedly connected with the bottom of the runner 151 and the bottom is fixedly connected with the top of the grinding plate 152. The ejector rod 153 moves upward in the inner chute of the runner 151, and then bounces back through the return spring 154 provided inside to make the grinding wheel 15 The pressing effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com