High-pressure extrusion dehydrator for garbage treatment

A extrusion dehydrator and waste disposal technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of long process time, low processing efficiency, and long process chain of finished products, so as to reduce moisture content, increase efficiency, and improve extrusion effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

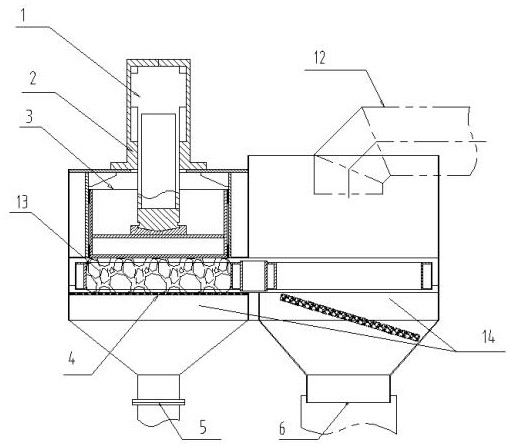

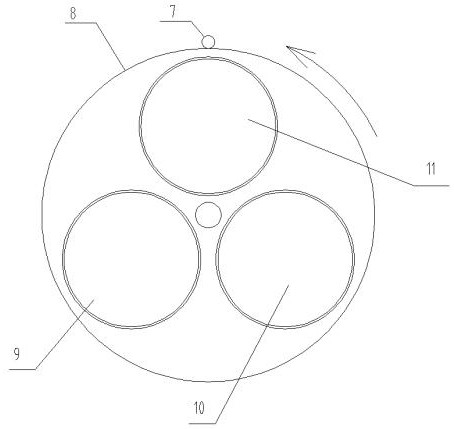

[0025] A high-pressure extrusion dehydrator for waste treatment, characterized by comprising: a dehydrator main body 1, a main pressure cylinder 2, a pressure head 3, a filter plate 4, a wet material outlet 5, a dry material outlet 6, and a rotating motor 7 , material turntable 8, first silo 9, second silo 10, third silo 11, feed station 12, extrusion station 13 and discharge station 14, said dehydrator main body 1 is provided with The main pressure oil cylinder 2, the bottom of the main pressure oil cylinder 2 is provided with a pressure head 3 for compressing kitchen waste and kitchen waste, and the bottom of the main body 1 of the dehydrator is provided with a pressure head 3 for filtering kitchen waste and food waste. The filter hole plate 4, the bottom of the filter hole plate 4 is provided with a wet material outlet 5, the material turntable 8 is arranged between the main body of the dehydrator 1 and the filter hole plate 4, and the dry material outlet 6 is arranged on th...

Embodiment 2

[0027] A high-pressure extrusion dehydrator for waste treatment, characterized by comprising: a dehydrator main body 1, a main pressure cylinder 2, a pressure head 3, a filter plate 4, a wet material outlet 5, a dry material outlet 6, and a rotating motor 7 , material turntable 8, first silo 9, second silo 10, third silo 11, feed station 12, extrusion station 13 and discharge station 14, said dehydrator main body 1 is provided with The main pressure oil cylinder 2, the bottom of the main pressure oil cylinder 2 is provided with a pressure head 3 for compressing kitchen waste and kitchen waste, and the bottom of the main body 1 of the dehydrator is provided with a pressure head 3 for filtering kitchen waste and food waste. The filter hole plate 4, the bottom of the filter hole plate 4 is provided with a wet material outlet 5, the material turntable 8 is arranged between the main body of the dehydrator 1 and the filter hole plate 4, and the dry material outlet 6 is arranged on th...

Embodiment 3

[0033] A high-pressure extrusion dehydrator for waste treatment, characterized by comprising: a dehydrator main body 1, a main pressure cylinder 2, a pressure head 3, a filter plate 4, a wet material outlet 5, a dry material outlet 6, and a rotating motor 7 , material turntable 8, first silo 9, second silo 10, third silo 11, feed station 12, extrusion station 13 and discharge station 14, said dehydrator main body 1 is provided with The main pressure oil cylinder 2, the bottom of the main pressure oil cylinder 2 is provided with a pressure head 3 for compressing kitchen waste and kitchen waste, and the bottom of the main body 1 of the dehydrator is provided with a pressure head 3 for filtering kitchen waste and food waste. The filter hole plate 4, the bottom of the filter hole plate 4 is provided with a wet material outlet 5, the material turntable 8 is arranged between the main body of the dehydrator 1 and the filter hole plate 4, and the dry material outlet 6 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com