Lower box body of power battery

A power battery and box technology, which is applied in the field of the box under the power battery, can solve the problems of water-cooling plate damage, insufficient impact resistance of the box, and low overall result strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be further described below in conjunction with the drawings and embodiments.

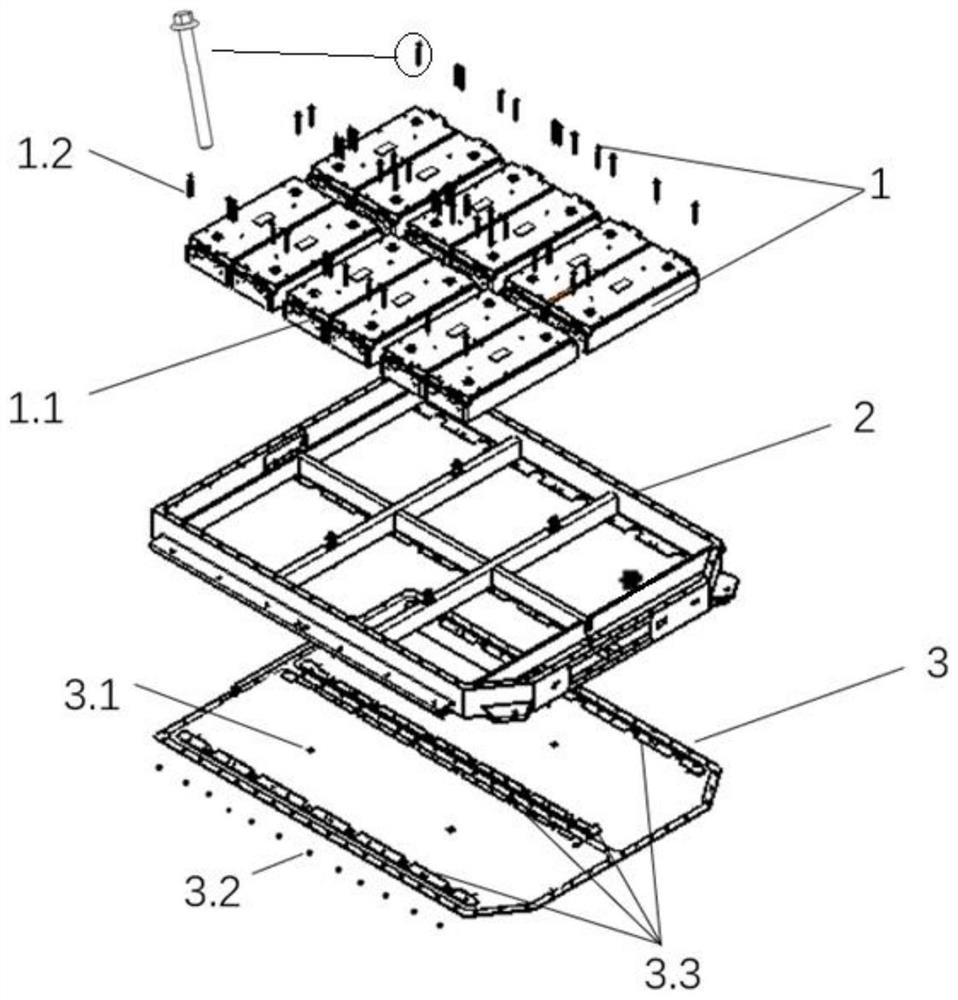

[0027]Such asfigure 1 As shown, a power battery lower box includes: power battery module assembly 1, including 590 module 1.1 and M8 long bolt 1.2 for fixing the module; frame beam assembly 2 of aluminum profile longitudinal and cross beam welding assembly; high The lower base plate 3 made of high-strength steel is suitable for the integration of 590 large-module lithium batteries. The power battery module assembly 1 and the frame beam assembly 2 and the lower base plate 3 are mechanically connected into a group by bolts.

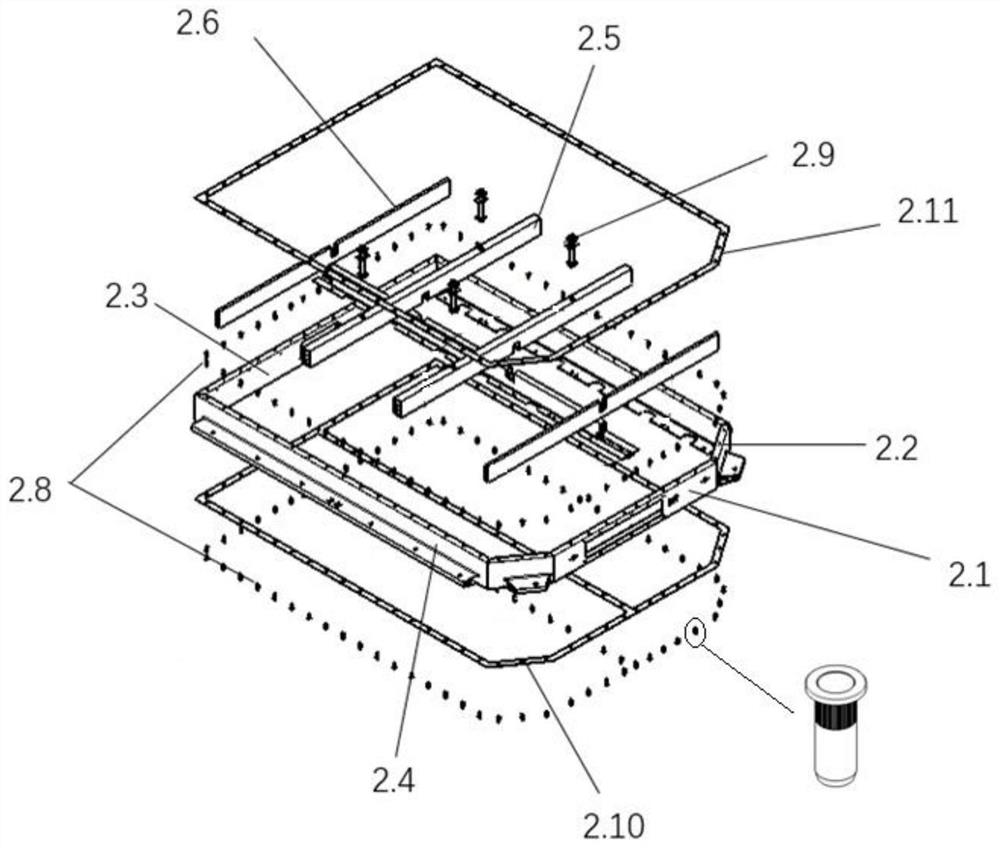

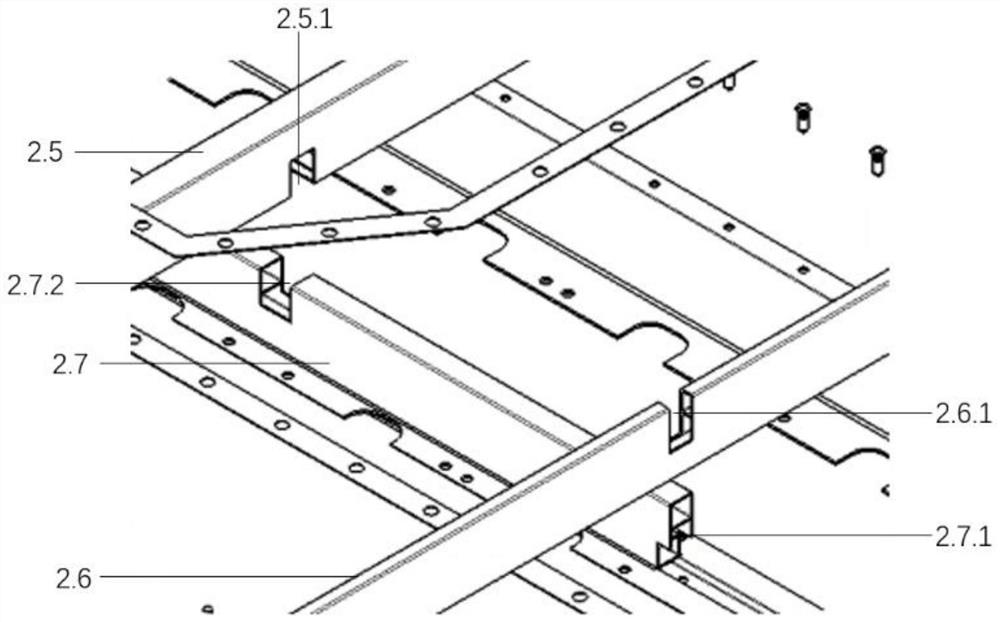

[0028]Such asFigure 1 to Figure 3As shown, the frame beam assembly 2 includes surrounding side beams and inner beams located in the side beams. The side beams include front side beam 2.1, rear side beam 2.3, left and right side beams 2.4, and corners connecting front side beam 2.1 and left and right side beam 2.4. Side beam 2.2, inner beam includes at least 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com