Adhesive tape

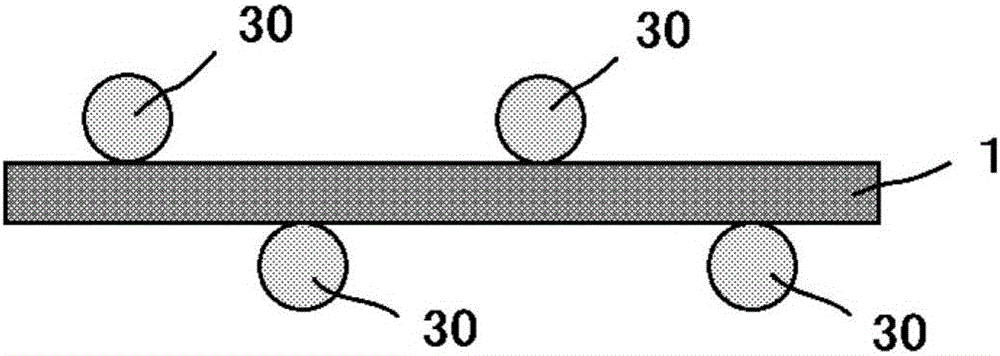

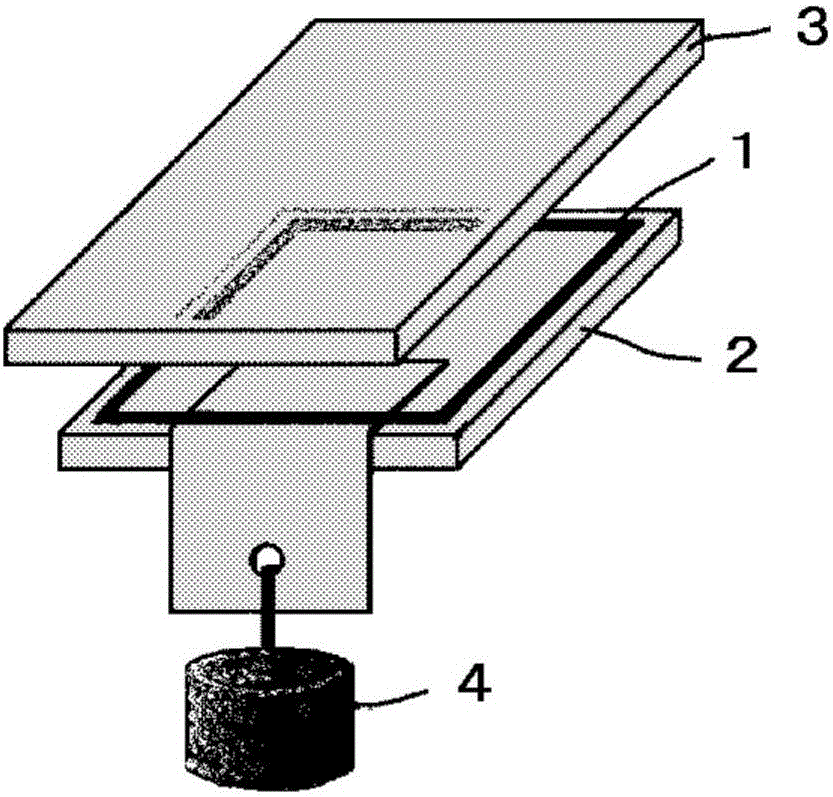

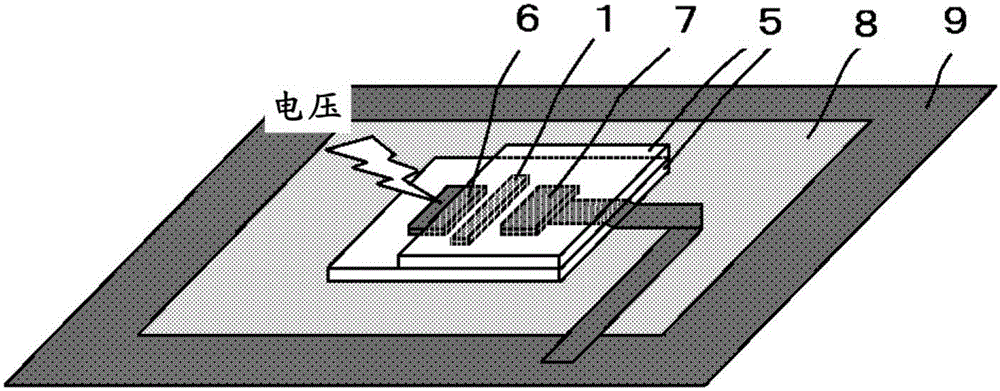

A technology of adhesive tape and adhesive layer, which is applied in the field of adhesive tape, can solve the problems of inability to evaluate impact resistance and antistatic property, and achieve the effect of excellent extrusion force and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1~3

[0056] Add the components (A1)~(A5) of the amount (%) shown in Table 1 in the reaction device that has stirrer, thermometer, reflux cooler and nitrogen gas introduction pipe, and ethyl acetate, the n-dodecanoate as chain transfer agent Mercaptan and 0.1 part of lauroyl peroxide as a peroxide-based radical polymerization initiator. Nitrogen gas was enclosed in the reaction apparatus, and the polymerization reaction was carried out at 68° C. for 3 hours under nitrogen flow while stirring, and then the polymerization reaction was carried out at 78° C. for 3 hours. Then, after cooling to room temperature, ethyl acetate was added. Thus, an acrylic copolymer (A) with a solid content concentration of 30% was obtained.

[0057] Table 1 shows the weight average molecular weight (Mw) and theoretical Tg of each acrylic copolymer. This weight average molecular weight (Mw) is the value obtained by measuring the molecular weight of the standard polystyrene conversion of an acrylic-type co...

Embodiment 4

[0083] In addition to using a base material composed of a PE-based foam containing 70% EVA (thickness = 0.15mm, tensile modulus = 46.2N / mm 2 , Bending moment = 18gf / cm, expansion ratio = 1.7, density = 590kg / m 3 ) was used as a base material, a double-sided adhesive tape was obtained in the same manner as in Example 1.

Embodiment 5

[0085] In addition to using a base material composed of a PE-based foam containing 70% EVA (thickness = 0.2mm, tensile modulus = 36.6N / mm 2 , Bending moment = 18gf / cm, expansion ratio = 2.9, density = 356kg / m 3 ) was used as a base material, a double-sided adhesive tape was obtained in the same manner as in Example 1.

[0086]

[0087] Except for using a PE-based foam (manufactured by Sekisui Chemical Industry Co., Ltd., trade name VOLARAXL-HT#030012, thickness = 0.2mm, tensile modulus = 21.0N / mm 2 , Bending moment = 3gf / cm, expansion ratio = 3, density = 330kg / m 3 ) was used as a base material, a double-sided adhesive tape was obtained in the same manner as in Example 1.

[0088]

[0089] Except for the use of PE-based foam (manufactured by Sekisui Chemical Industry Co., Ltd., trade name VOLARAXL-H#0180015, thickness = 0.15mm, tensile modulus of elasticity = 23.7N / mm 2 , Bending moment = 7gf / cm, expansion ratio = 1.8, density = 560kg / m 3 ) was used as a base material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com