Anti-ultraviolet, anti-corrosion, anti-water, loadable and anti-extrusion magnetic measuring cable for ship

An anti-ultraviolet and anti-corrosion technology, applied in the direction of insulated cables, cables, circuits, etc., to improve the bearing capacity, easy to use, and excellent load force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

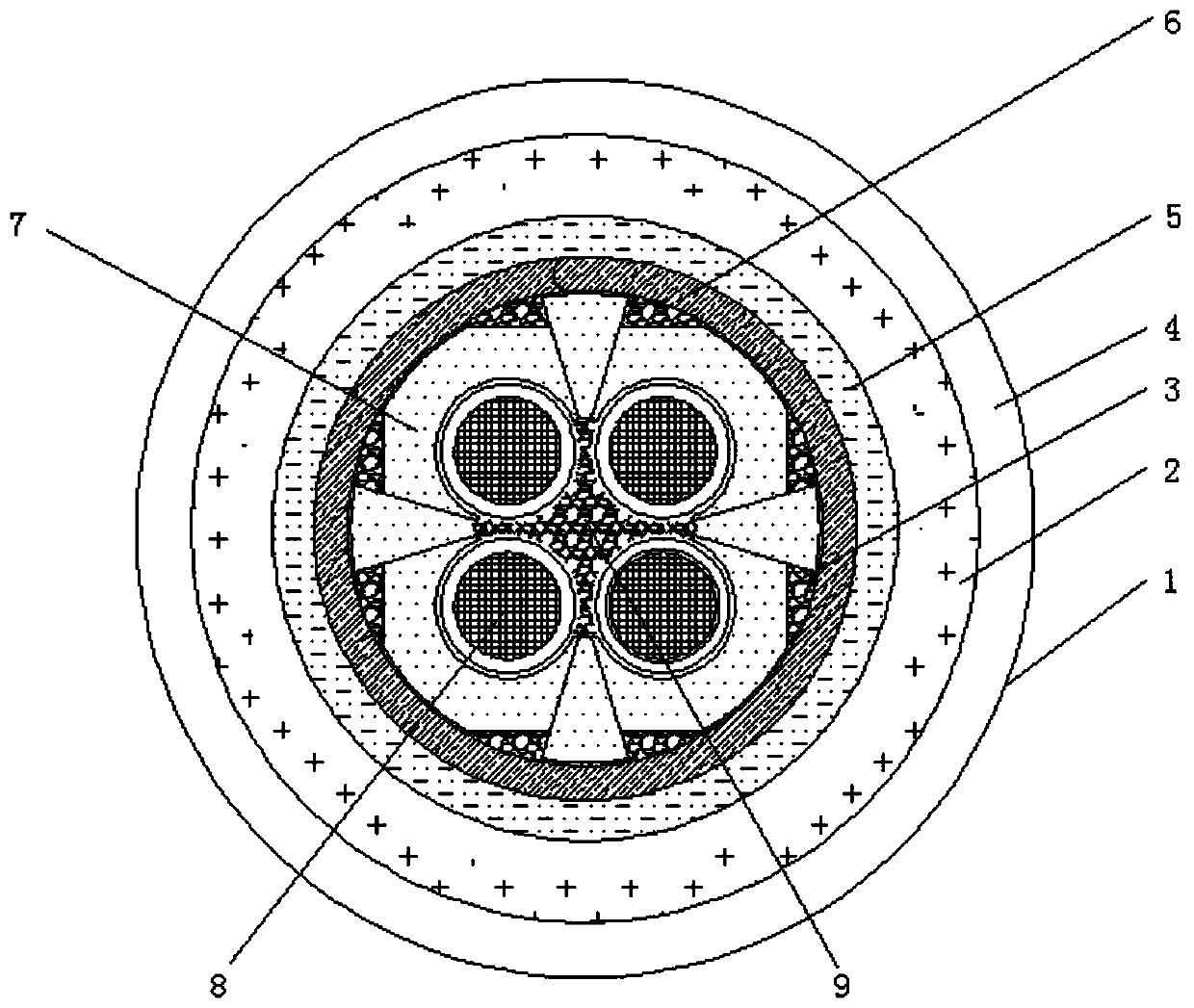

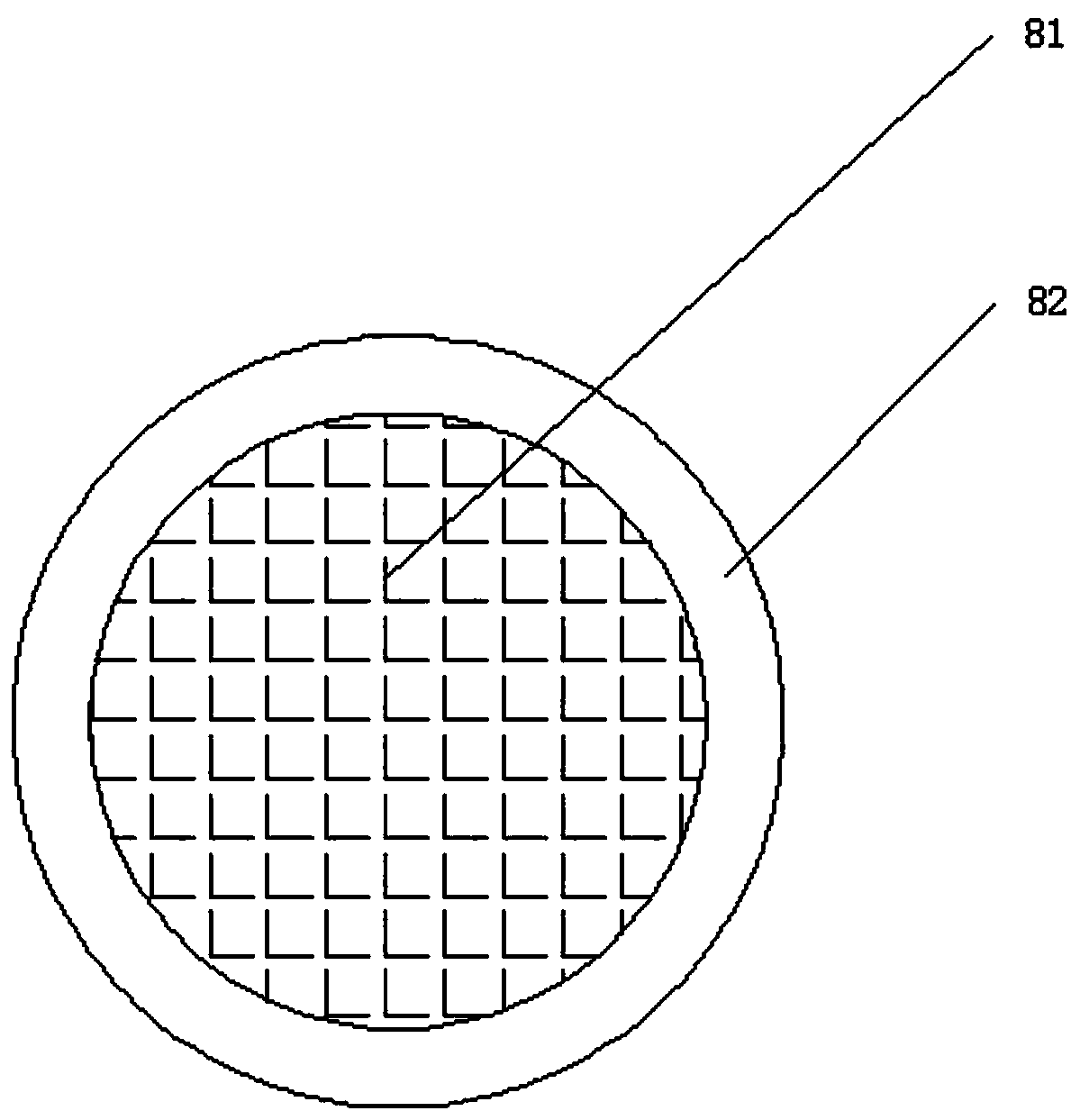

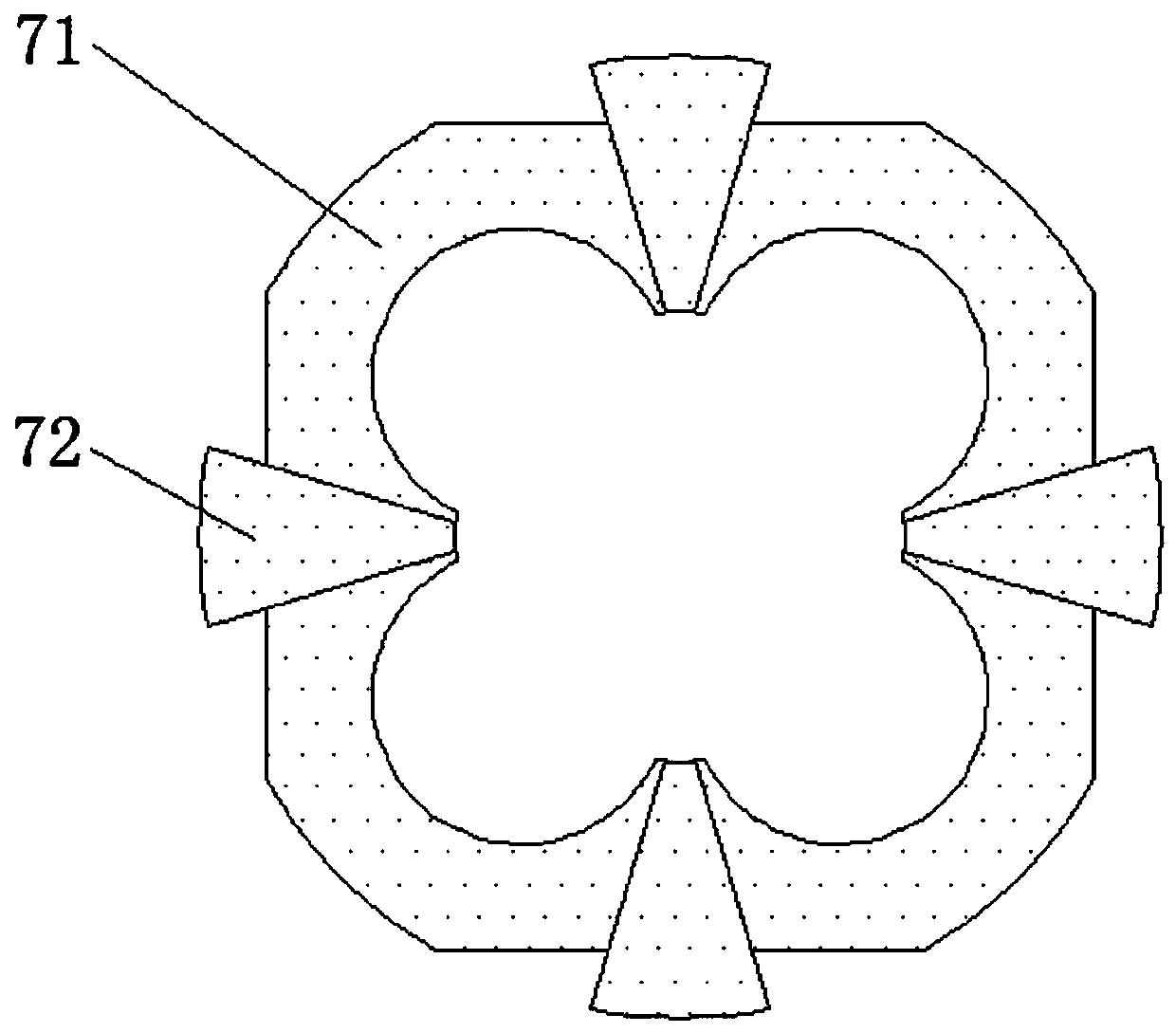

[0026] Such as Figure 1-6 The shown anti-ultraviolet, anti-corrosion, water-resistance, load-resistant and extrusion-resistant magnetic measuring cable for ships includes a cable body 1, a bracket 7 is arranged in the middle of the cable body, and the bracket 7 includes four protective strips 71 and four sliding Bar 72, four protective strips 71 and four sliding strips 72 are arranged at intervals, and the protective strips 71 and sliding strips 72 are slidably connected, the inner side of the protective strip 71 is provided with a groove 711, and the outer side of the protective strip 71 is provided with an arc-shaped portion. 712, the two sides of the protection strip 71 are provided with an inclined surface 1 713 inclined to the arc portion 712, the outer side of the slide bar 72 is provided with an arc portion 721, the inner side of the slide bar 72 is provided with an inner concave portion 722, and the slide bar 72 Both sides are provided with inclined plane 2 723 inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com