Preparation technique of embossing plate roller

An embossed plate roll and preparation process technology, applied in the field of embossed plate roll preparation technology, can solve problems such as easy breakage, unclear lines, blurred lines, etc., and achieve the effects of not easy to break and wear, rich layers, and clear lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A preparation process for an embossed plate roll, comprising the following steps:

[0015] 1) Roll body material selection and welding pre-processing, the specific steps are: A, the roll body selects steel pipes with no burrs, scratches and pipe body deformation on the surface, and cuts the steel pipes into equal-length steel pipes by a pipe cutting machine. The slit roller shaft, the shaft head is blocked with a round steel flange, and it is reserved; B. Use a turning machine to turn the joint surface of the roller body and the joint surface of the round steel flange, so that the roller body and the round steel method The blue plate can be closely matched and is ready for use; C. Preheat the roller body and the round steel flange after the specific step B to raise the temperature to 250°C, and then put the preheated roller body and the round steel flange The discs are closely matched, and then welded by an argon arc welding machine in a windless environment indoors, so...

Embodiment 2

[0021] A preparation process for an embossed plate roll, comprising the following steps:

[0022] 1) Roll body material selection and welding pre-processing, the specific steps are: A, the roll body selects steel pipes with no burrs, scratches and pipe body deformation on the surface, and cuts the steel pipes into equal-length steel pipes by a pipe cutting machine. The slit roller shaft, the shaft head is blocked with a round steel flange, and it is reserved; B. Use a turning machine to turn the joint surface of the roller body and the joint surface of the round steel flange, so that the roller body and the round steel method The blue plate can be closely matched and is ready for use; C. Preheat the roller body and the round steel flange processed in the specific step B to raise the temperature to 300°C, and then put the preheated roller body and the round steel flange The discs are closely matched, and then welded by an argon arc welding machine in a windless environment indo...

Embodiment 3

[0028] A preparation process for an embossed plate roll, comprising the following steps:

[0029] 1) Roll body material selection and welding pre-processing, the specific steps are: A, the roll body selects steel pipes with no burrs, scratches and pipe body deformation on the surface, and cuts the steel pipes into equal-length steel pipes by a pipe cutting machine. The slit roller shaft, the shaft head is blocked with a round steel flange, and it is reserved; B. Use a turning machine to turn the joint surface of the roller body and the joint surface of the round steel flange, so that the roller body and the round steel method The blue plate can be closely matched and is ready for use; C. Preheat the roller body and the round steel flange processed in the specific step B to raise the temperature to 275°C, and then put the preheated roller body and the round steel flange The discs are closely matched, and then welded by an argon arc welding machine in a windless environment indo...

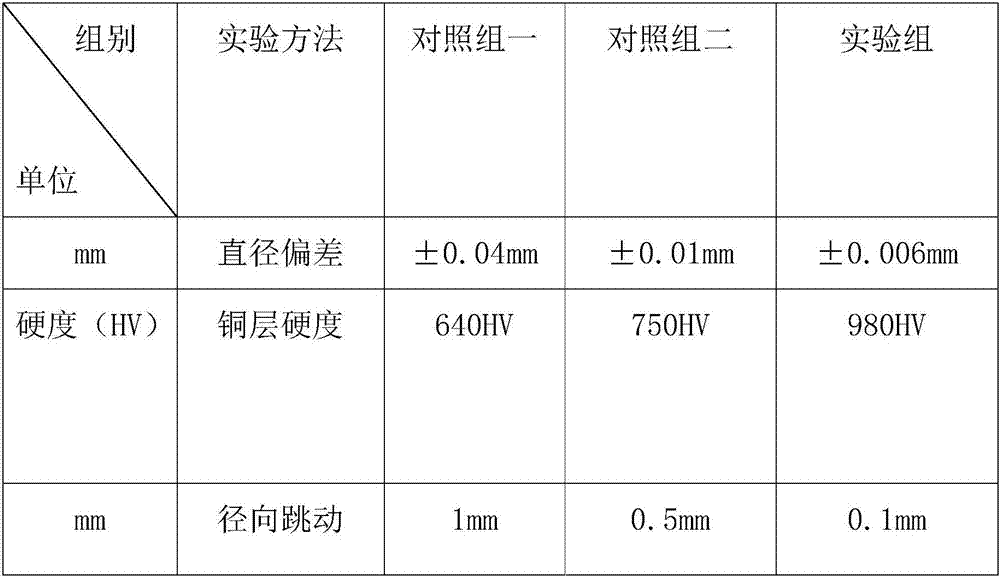

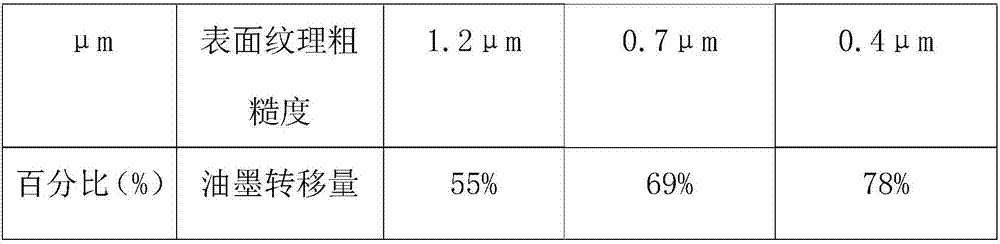

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com