A kind of mechanochemical method for synthesizing lithium magnesium silicate

A technology for synthesizing magnesium silicate and mechanochemistry, applied in the direction of non-metallic elements, etc., can solve the problems of large-scale production of magnesium-lithium silicate, high input and operating costs, increased material viscosity, etc., and achieve low cost and short reaction time Effect of shortening and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Precursor preparation:

[0039] (1) 860g water glass (SiO 2 28wt%,Na 2 (09wt%, modulus 3.22) is dissolved in 4L water, then adds 162g H rapidly while stirring 2 SO 4 ;

[0040] (2) 560g MgCl 2 ·6H 2 O dissolved in 1L of water;

[0041] (3) Add the solution of step (2) into the slurry obtained in step (1), and stir evenly;

[0042] (4) Keep stirring continuously and slowly add 2.4L of 3N NaOH solution to make coprecipitation precursor slurry;

[0043] (5) centrifuging the co-precipitation precursor slurry, and fully washing the centrifuged filter cake with clear water to obtain the washed slurry;

[0044] (6) 14.5g LiOH·H 2 O is dissolved in 200g of water;

[0045] (7) Add the solution of step (6) into the slurry after washing in step (5), and stir evenly;

[0046] (8) Heating while stirring, so that the temperature of the system reaches 70° C. to obtain a precursor.

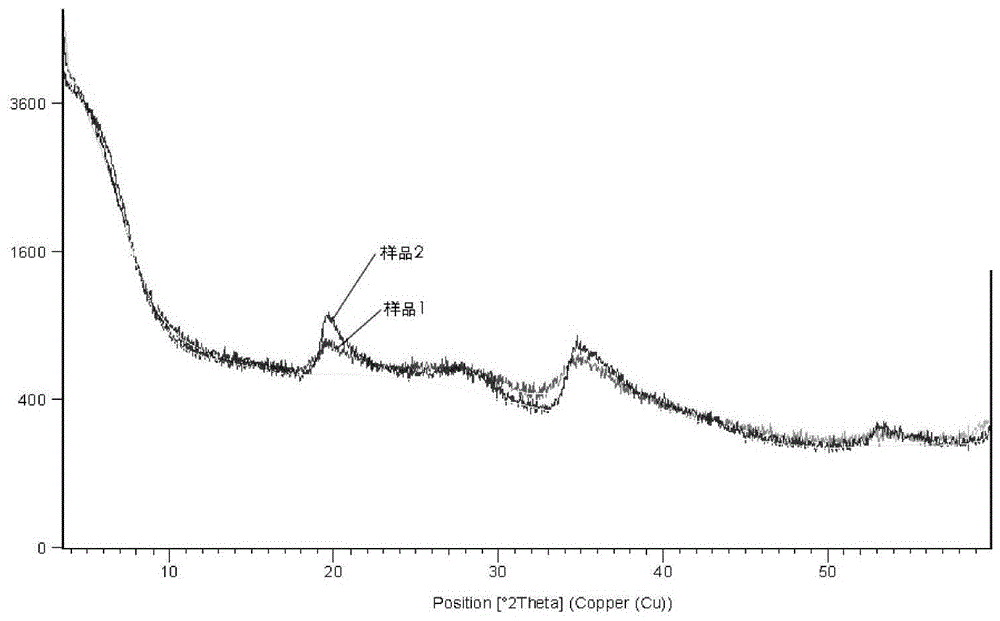

[0047]The prepared precursor was input into a nano ball mill, the grinding medium was zirco...

Embodiment 2

[0049] Precursor preparation:

[0050] (1) 800g water glass (SiO 2 12.5wt%, Na 2 O3.9wt%, modulus 3.54) was dissolved in 4L water, and then 143g HNO was added quickly while stirring 3 ;

[0051] (2) 530g MgSO 4 Dissolve in 1L of water;

[0052] (3) Add the solution of step (2) into the slurry obtained in step (1), and stir evenly;

[0053] (4) Keep stirring continuously and slowly add 1L of ammonia water to make co-precipitation precursor slurry.

[0054] (5) centrifuging the co-precipitation precursor slurry, and fully washing the centrifuged filter cake with clear water to obtain the washed slurry;

[0055] (6) 29.4g LiOH·H 2 O is dissolved in 400g of water;

[0056] (7) Add the solution of step (6) into the slurry after washing in step (5), and stir evenly;

[0057] (8) Heating while stirring, so that the temperature of the system reaches 30° C. to obtain a precursor.

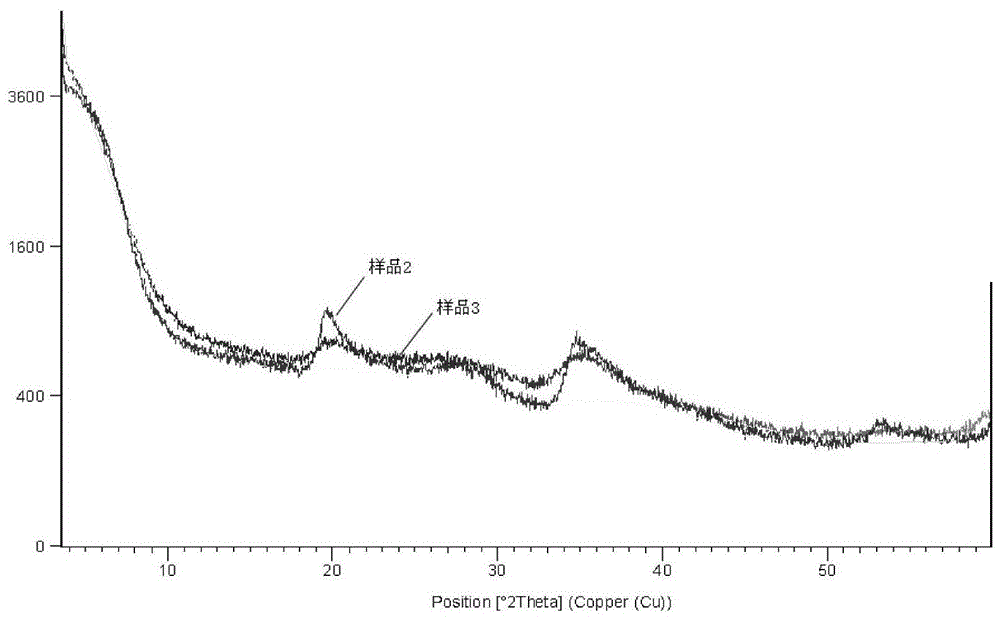

[0058] The prepared precursor was input into a nano-sand mill, the grinding medium was yttrium-...

Embodiment 3

[0060] Precursor preparation:

[0061] (1) 880g water glass (SiO 2 12.5wt%, Na 2 (03.9wt%, modulus 3.54) is dissolved in 5L water, then adds 120g HCl rapidly while stirring;

[0062] (2) 620g Mg(NO 3 ) 2 Dissolve in 2L water;

[0063] (3) Add the solution of step (2) into the slurry obtained in step (1), and stir evenly;

[0064] (4) Keep stirring continuously and slowly add 2L of ammonia water to make co-precipitation precursor slurry.

[0065] (5) centrifuging the co-precipitation precursor slurry, and fully washing the centrifuged filter cake with clear water to obtain the washed slurry;

[0066] (6) 25g LiOH·H 2 O is dissolved in 400g of water;

[0067] (7) Add the solution of step (6) into the slurry after washing in step (5), and stir evenly;

[0068] (8) Heating while stirring, so that the temperature of the system reaches 50° C. to obtain a precursor.

[0069] The prepared precursor was input into a peeling machine, the grinding medium was zirconium silicate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com