Tail-cover-free embedding process of electric connector and testing method

A technology of electrical connectors and process methods, which is applied in the field of tailless potting and sealing technology and testing, which can solve problems such as disconnection, cable disconnection, and stress on solder joints, so as to improve the quality of potting, reduce production costs, and ensure firmness The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings.

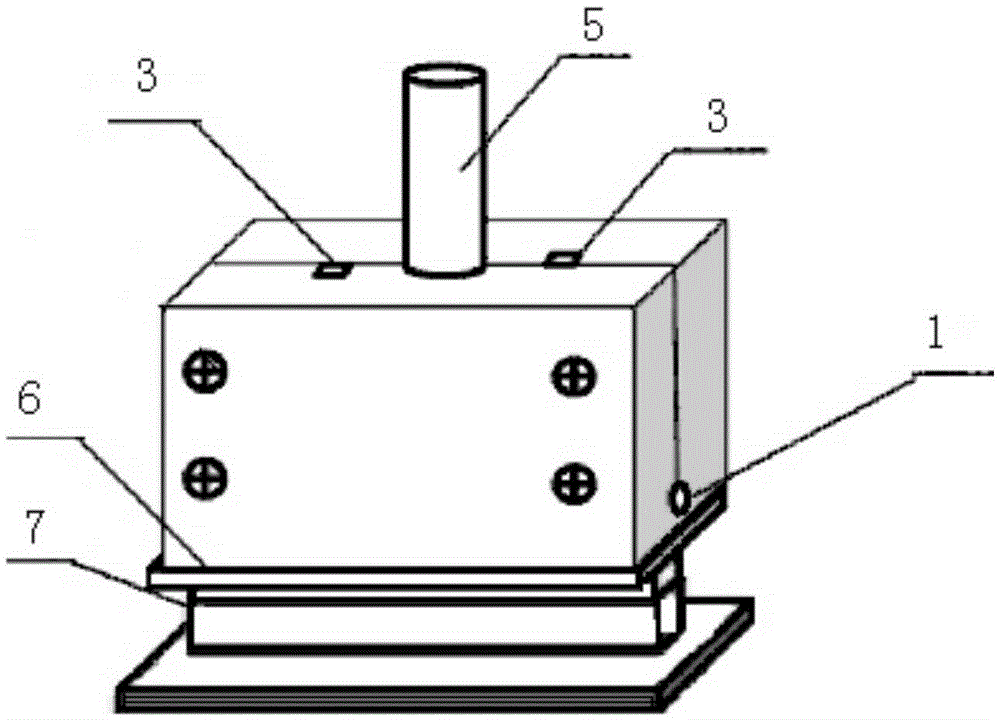

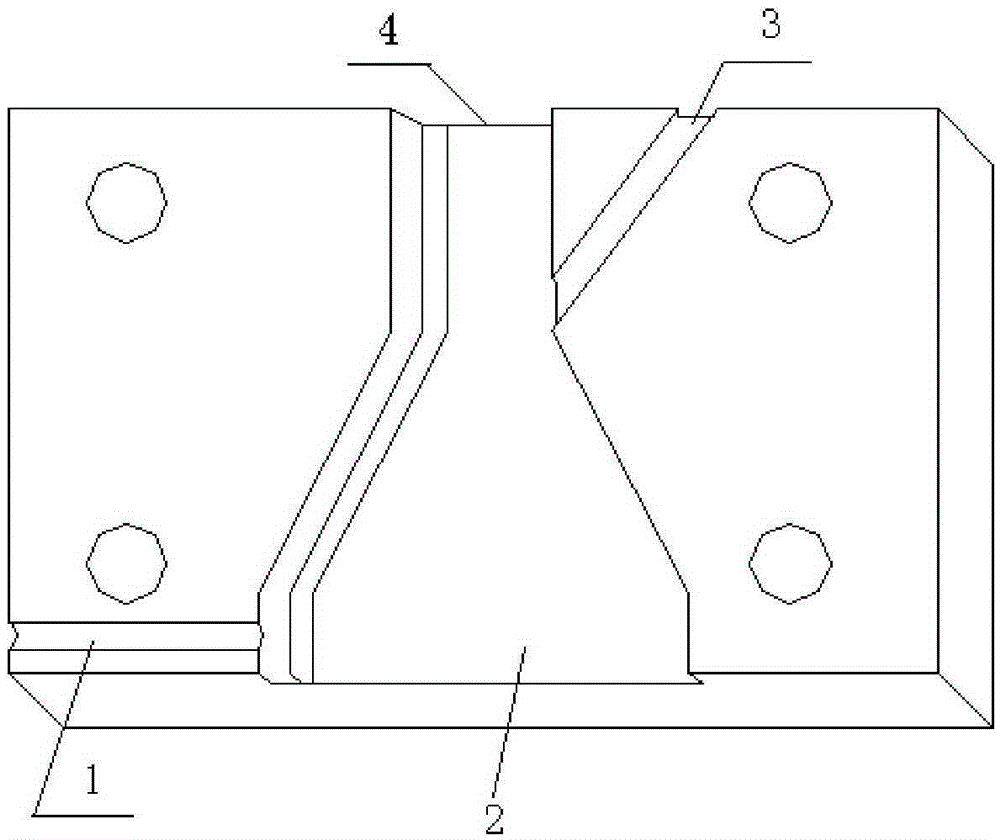

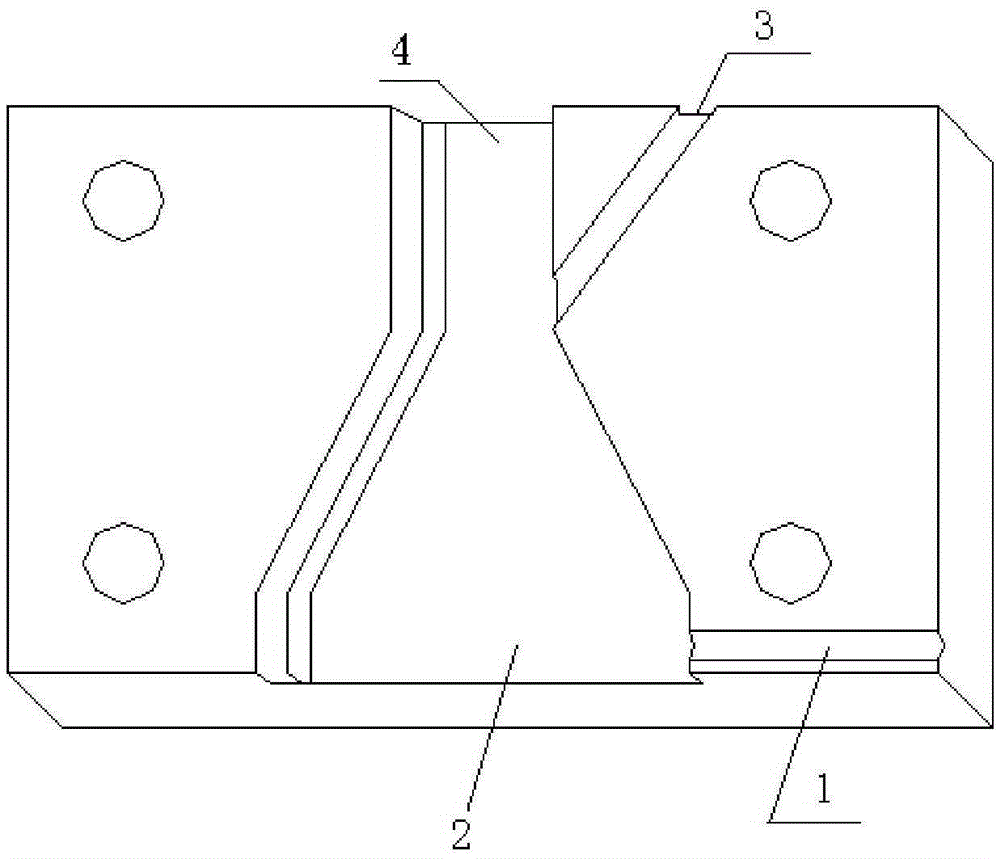

[0033] The invention can well fill the gaps between the pins of the electric connector during potting by selecting potting glue with good fluidity. Through the design of the potting mold, the potting mold and the electrical connector are fixed, and the glue is injected from the bottom of the mold to facilitate the discharge of air bubbles. The potting is completed after the glue reaches the potting height, and the gap-free potting of the high-electricity connector is realized.

[0034] The specific implementation steps follow the following principles:

[0035] a) The potting mold of the spacecraft cable net must meet the principle of sufficient exhaust, and the use of glue from the bottom of the mold is conducive to the discharge of air bubbles;

[0036] b) Easy to assemble and easy to disassemble;

[0037] c) Tight fit to prevent the glue from overflowing;

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com