Automatic cutting device for production of triangular belt of oil pumping unit

A technology of automatic cutting device and V-belt, which is applied in the direction of metal processing, etc., can solve the problems of irregular cutting edges, incorrect position placement, and reserved V-belt sleeves, and achieve the effect of preventing position deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

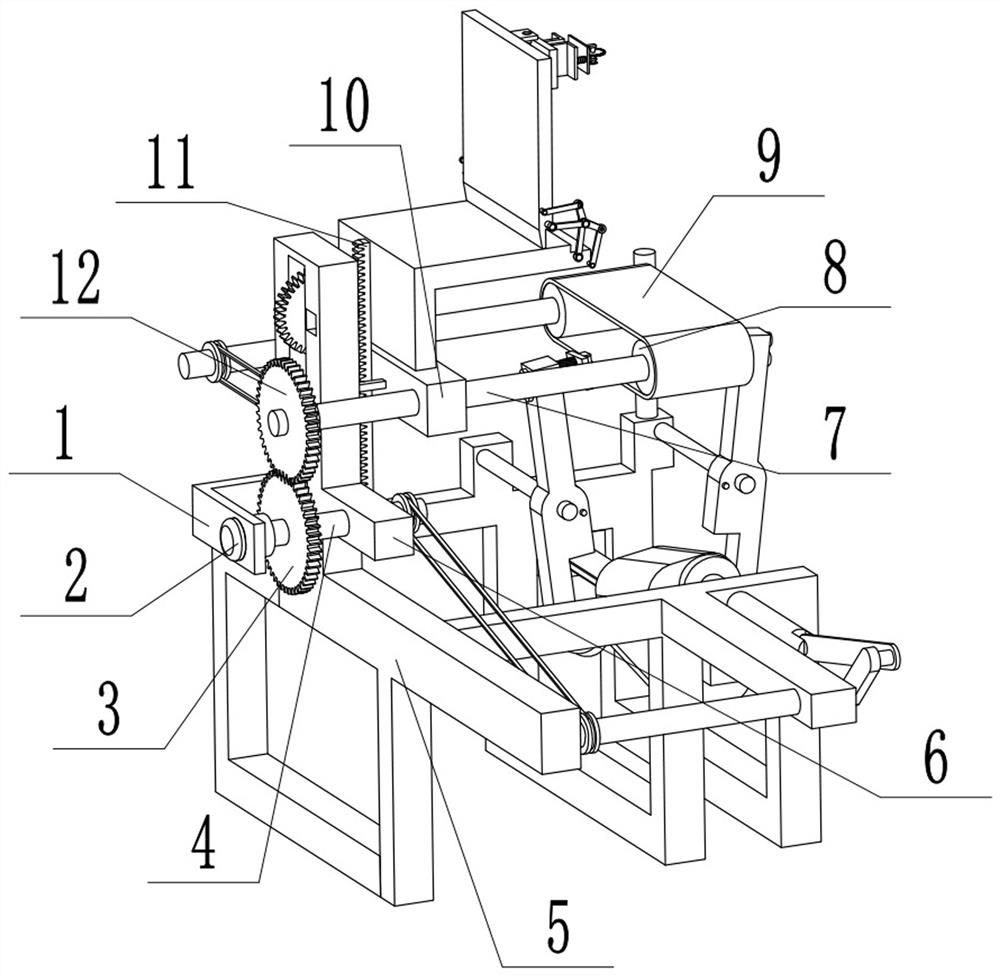

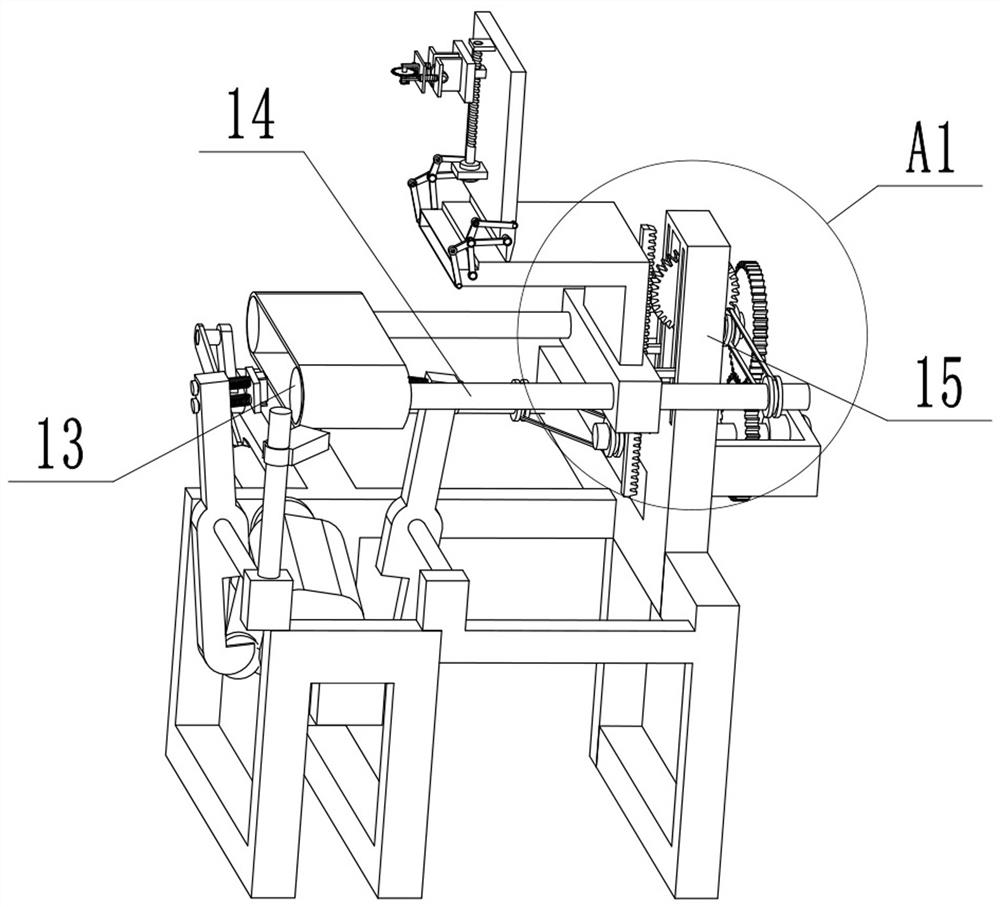

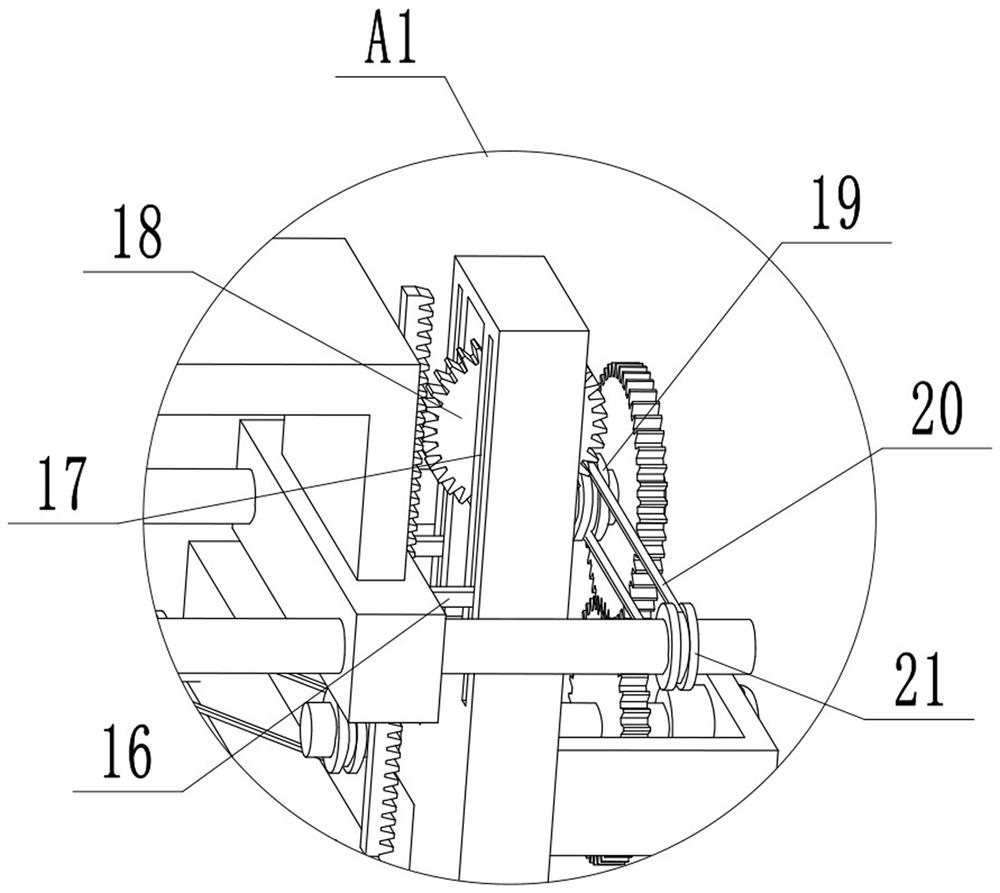

[0033] Example: Figure 1 - Figure 16 Pumping Unit production belt illustrated automatic cutting apparatus, a small bracket fixedly mounted on the holder 15 is placed, it is placed on a holder 15 fixedly mounted transfer holder 5, the active force of the motor 2 is fixedly mounted in a small holder 1, the main gear 3 is fixedly mounted on the main shaft 4, main shaft 4 is fixedly mounted on the output shaft of the active force of the motor 2, a main shaft 4 rotatably installed on the main mount 6, the main mount 6 is fixedly mounted in a fixed place 15, a first rotatably mounted lever 7 is placed on the placement base 10 is placed on the holder 10 is placed is fixed with a rack 11 is mounted, is placed with a seat 10 fixedly mounted on the slide bar 16 is placed, is placed in the slide bar 16 slidably mounted carriage disposed groove 17, the chute 17 is placed on the holder 15 is placed is provided, a first roller 8 is fixedly mounted on the first lever 7 is placed, the second leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com