Pre-branch cable production and processing system

A processing system and pre-branching technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of large influence of pre-branched cables and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

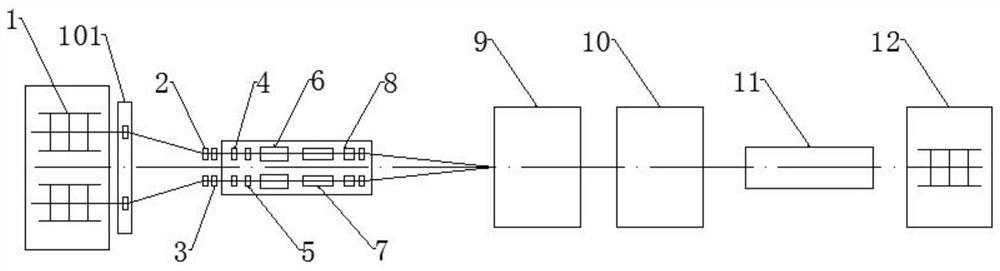

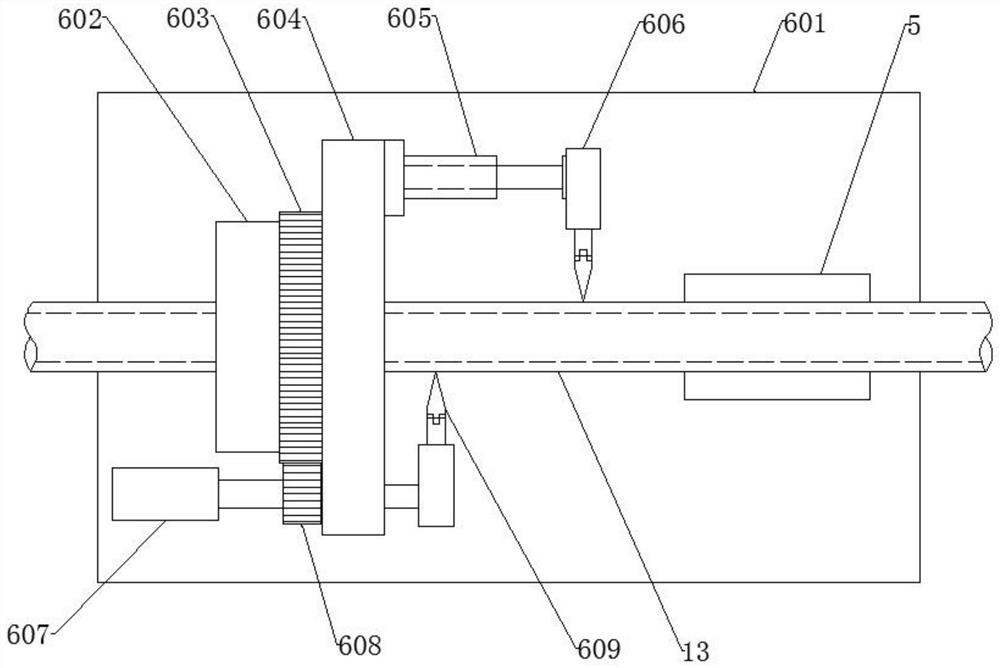

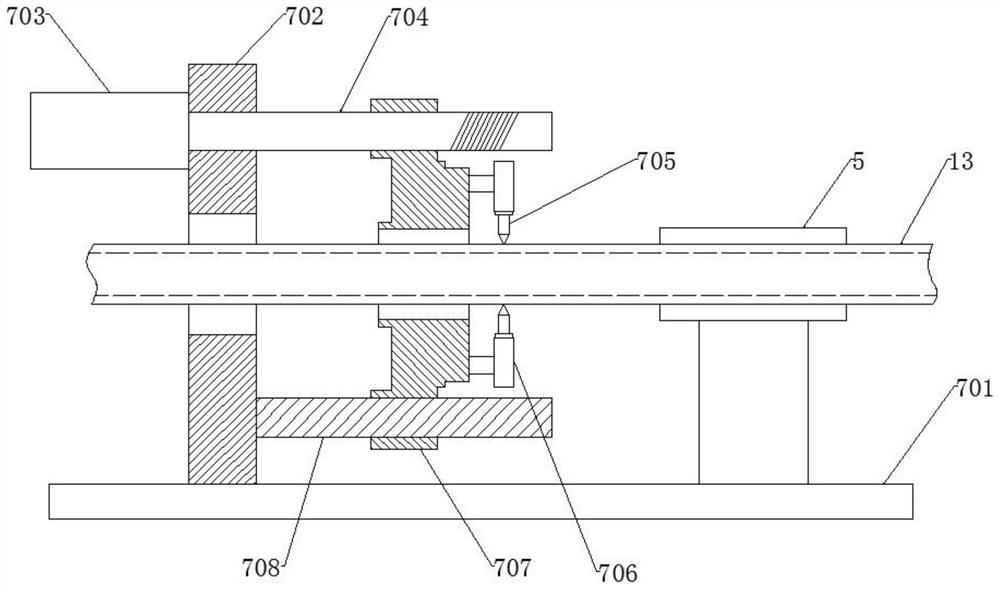

[0020] The reference signs in the accompanying drawings of the specification include: pay-off wheel 1, wire rack 101, front guide wheel 2, meter counter 3, rear guide wheel 4, cable clamp 5, clamping plate one 501, clamping plate two 502, Clamping cavity 503, tine 1 504, tine 2 505, circular cutter 6, workbench 601, bearing seat 602, driven gear 603, turntable 604, telescopic rod 605, telescopic motor 606, driving motor 607, driving gear 608, circumcision blade 609, slitter 7, support seat 701, support plate 702, horizontal drive motor 703, screw mandrel 704, cutting knife 705, push cylinder 706, sliding seat 707, guide rod 708, shears 8, wiring Machine 9, injection molding machine 10, tractor 11, take-up machine 12, cable 13.

[0021] The embodiment is basically as attached figure 1 Shown: the pre-branch cable production and processing system, including a pay-off machine, a wire s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com